A kind of weak solvent type ink-jet medium and preparation method thereof

A weak solvent, inkjet technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of no mention of drying speed, poor adhesion to the support, long drying time, etc., to achieve vivid color reproduction and good coating. Good effect of layer fastness and coating fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Modification of Inorganic Particles

[0074] Add 4 grams of titanium dioxide with a particle size of 10 microns, 2 grams of titanium dioxide with a particle size of 0.2 microns, silicon dioxide with a particle size of 10 microns, and 80 ml of water into the container, disperse at 10,000 rpm with high-speed stirring for 1 hour, and heat up to 70±1 ℃, 10 grams of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate and 2 ml of 1% hydrochloric acid were gradually injected into the dispersed inorganic particles at the same time, and the stirring was continued for 60 minutes, and the stirring speed was reduced to 200 rpm, the modification reaction was carried out for 6 hours, the modification reaction was terminated, and an inorganic particle modification liquid was prepared.

[0075] Preparation of Inkjet Receptor Layer Coating Liquid

[0076] Add polyacrylic acid emulsion, polyvinyl acetate emulsion, polyethylene emulsion, polyurethane emulsion and other polymer emulsio...

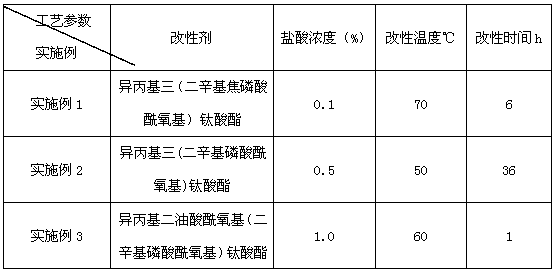

Embodiment 2~8

[0080] The types of inorganic particles used in the inorganic particle modification process in Examples 2 to 8, their particle sizes and their added amounts are shown in Table 1, and the types of modifiers, hydrochloric acid concentration, modification temperature, modification time and other process conditions are shown in Table 2. The content of each component of the coating solution is shown in Table 3, and the glass transition temperature of the polymer used is shown in Table 4. Others are in accordance with the operation of Example 1, respectively preparing weak solvent inkjet media 2-8.

[0081] Table 1 Condition of inorganic particles in the examples (unit: g)

[0082]

[0083] Table 2 Modifiers, hydrochloric acid concentration, modification temperature, modification time used in the examples

[0084]

[0085]

[0086] Table 3 Contents of components in the examples (unit: grams)

[0087]

[0088]Table 4 Glass transition temperature of polymer emulsion (unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com