A palladium-silver bimetallic composite material and a preparing method thereof

A composite material and bimetal technology, which is applied in the field of palladium-silver bimetal composite materials and its preparation, can solve the problems of low palladium activity and difficult electrochemical desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The application also provides the preparation method of above-mentioned palladium-silver bimetallic catalyst, comprising:

[0036] Silver nanocrystals, reducing agent, etchant, surface protection agent, solvent and palladium source compound are mixed and then reacted to obtain palladium-silver bimetal composite material.

[0037] In the process of preparing the palladium-silver bimetallic composite material, the application utilizes etchant, reducing agent and surface protection agent to make the palladium-silver bimetallic composite material prepared have silver nanoparticles as the core and a palladium-silver alloy layer as the core. Composite material for the shell.

[0038] In the process of preparing the palladium-silver bimetallic composite material, the present application mixes silver nanocrystals, reducing agent, etchant, surface protection agent, solvent and palladium source compound and reacts to obtain the palladium-silver bimetallic composite material; In ...

Embodiment 1

[0048] The preparation of embodiment 1 silver nanocrystal

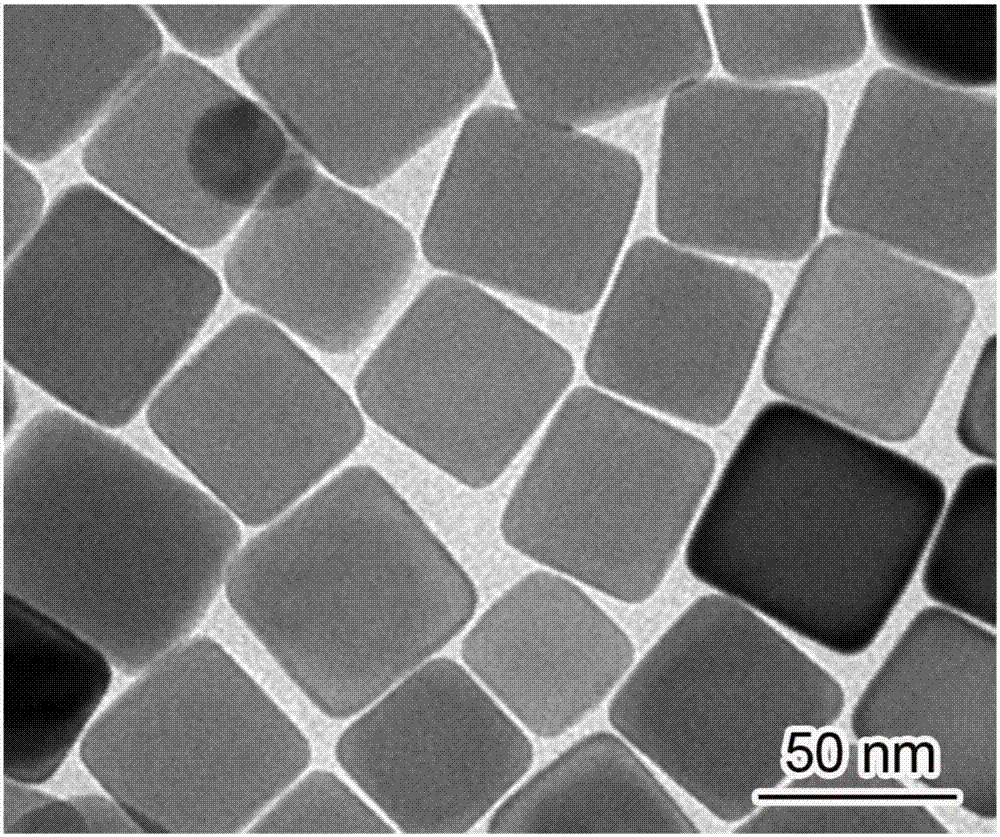

[0049] Add 50 milliliters of ethylene glycol into a 250 milliliter round-bottomed flask, heat the oil bath to 150 degrees Celsius and keep the temperature, while stirring at a constant speed with a magnet; quickly add 0.6 milliliters of 3 millimoles per liter of sodium hydrosulfide ethylene glycol solution, After 4 minutes, add 5 ml of 1 mol per liter hydrochloric acid aqueous solution, and after another 2 minutes, add 12.5 ml of 20 mg per ml of polyvinylpyrrolidone glycol solution, and after another 2 minutes, add 4 ml of 282 mmol per liter of tris Silver fluoroacetate ethylene glycol solution; keep the reaction mixed solution obtained above at 150 degrees Celsius for one hour under constant speed stirring; then wash out the sample with acetone and ethanol, and disperse it in a 10 ml centrifuge tube with water to obtain silver nanocrystals. The TEM photograph of the silver nanocrystal that present embodiment obtains ...

Embodiment 2

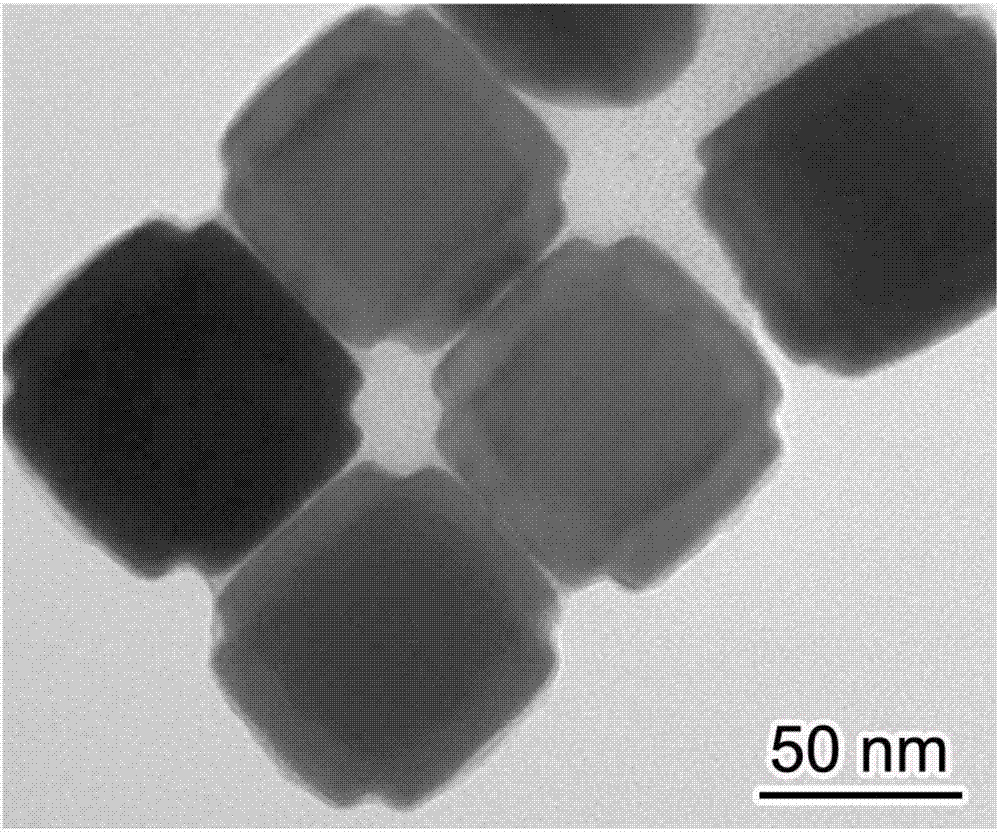

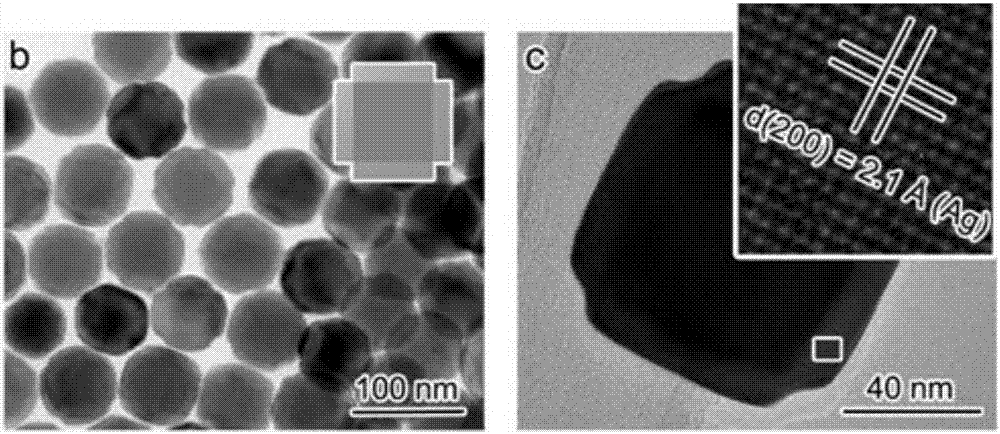

[0052] Mix 0.5mL oleylamine, 1mL 2mol / L hydrochloric acid aqueous solution, 0.03g ascorbic acid and 3.5mL ethylene glycol, heat in an oil bath at 80°C, and stir at a constant speed on a magnet; after preheating for 5 minutes, add 1mL containing 3mg palladium chloride Potassium acid potassium solution and 1mL silver nanocrystal solution, stir at constant speed 20min, wash out sample with n-hexanol subsequently, obtain palladium-silver bimetallic composite material; The TEM photo of the palladium-silver bimetallic composite material prepared in the present embodiment is as follows figure 2 as shown, figure 2 The scale bar is 50nm. image 3 Ordinary TEM and high-resolution TEM photographs of the palladium-silver bimetallic composite material prepared for Example 2 of the present invention, by image 3 It can be seen that the palladium-silver bimetallic composite material obtained in this example has a complete structure, and the internal silver nanoparticles are not damaged. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com