A Method Adapted to Carbon Dioxide Capture and Power Generation in Cement Kiln Flue Gas

A carbon dioxide and cement kiln technology, applied in chemical instruments and methods, separation methods, cement production, etc., can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

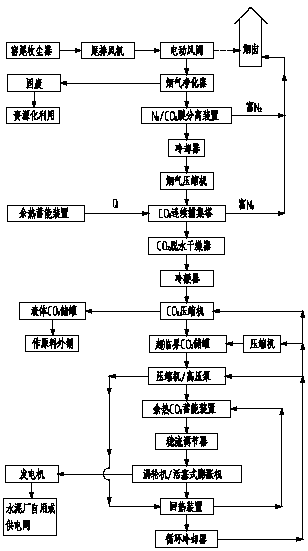

[0079] refer to figure 2 , one containing 2 sets of CO 2 Parallel capture of CO with continuous capture towers 2 , 2 sets of CO 2 A method for generating energy by an energy storage device mainly includes the following steps:

[0080] (1) Flue gas purification

[0081] An electric air valve is installed on the flue gas pipeline between the exhaust fan and the chimney after the dust collector at the end of the kiln in the cement plant to switch the direction of the flue gas, and the flue gas is continuously sent into the flue gas purifier by the power of the tail exhaust fan , using known methods such as "foam method / film bubble method / oxidation method" to purify harmful gaseous and dust pollutants in the flue gas and dehydrate them, the purified flue gas is continuously discharged from the gas outlet of the flue gas purifier, the flue gas purification process The solid waste generated in the process is discharged from the bottom of the flue gas purifier and utilized as a ...

Embodiment 2

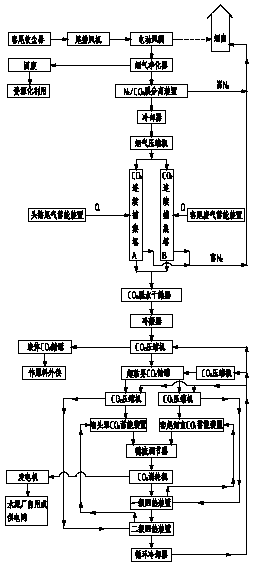

[0096] refer to image 3 , one containing 2 sets of CO 2 Continuous capture towers capture CO in series 2 , 2 sets of CO 2 A method for generating energy by an energy storage device mainly includes the following steps:

[0097] (1) Flue gas purification

[0098] An electric air valve is installed on the flue gas pipeline between the exhaust fan and the chimney after the dust collector at the end of the kiln in the cement plant to switch the direction of the flue gas, and the flue gas is continuously sent into the flue gas purifier by the power of the tail exhaust fan , using known methods such as "foam method / film bubble method / oxidation method" to purify harmful gaseous and dust pollutants in the flue gas and dehydrate them, the purified flue gas is continuously discharged from the gas outlet of the flue gas purifier, the flue gas purification process The solid waste (solid waste) generated in the process is discharged from the bottom of the flue gas purifier and utilized...

Embodiment 3

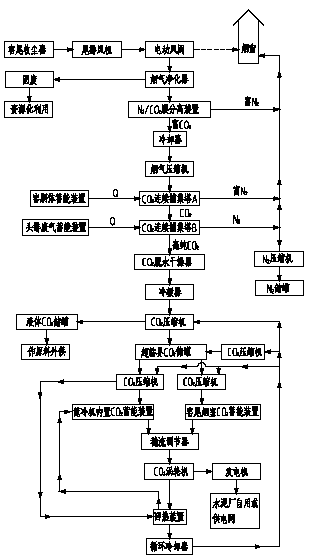

[0113] refer to Figure 4 , the dust content of flue gas from the kiln tail dust collector of the cement plant is 10mg / Nm 3 And when there are no harmful pollutants such as heavy metals, one contains 2 sets of CO 2 Continuous capture towers capture CO in series 2 , 2 sets of CO 2 A method for generating energy by an energy storage device mainly includes the following steps:

[0114] (1) CO 2 connection capture

[0115] CO with two sets in series 2 Continuous capture tower A and CO 2 Continuous capture column B to increase captured CO 2 purity;

[0116] An electric air valve is installed on the flue gas pipeline between the exhaust fan and the chimney after the dust collector at the end of the kiln in the cement factory. Cooling and flue gas compressor compression, continuously fed into the first set of CO set in series 2 Continuous capture tower A, CO 2 N-rich continuously discharged from the continuous capture tower A 2 The gas is directly evacuated through the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com