Preparation method for NiTe2 used for electrode material of supercapacitor

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors. It can solve the problems of environmental pollution restrictions, low energy density, poor conductivity, etc., and achieve simple preparation process and large electrode specific surface area. , short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

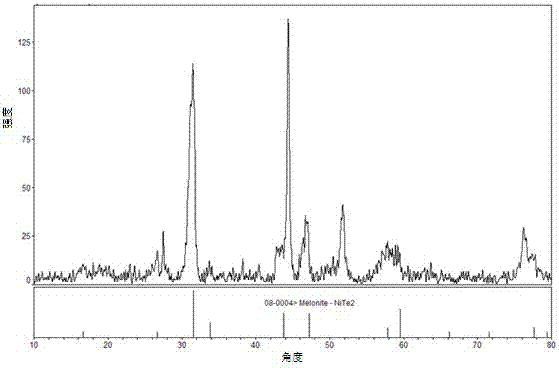

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with specific examples.

[0025] The experimental procedure of embodiment 1~4 is as follows:

[0026] 1. Weigh tellurium source (Te powder) and nickel source according to the molar number in Table 1; put the weighed material into a polytetrafluoroethylene reactor, add reducing agent hydrazine hydrate and an appropriate amount of solvent, and stir to form a mixed solution; The selection of concrete consumption and solvent is as shown in table 1;

[0027] 2. Put the foamed nickel sheet into the mixed solution; put the reactor into the heating furnace and react at a certain temperature for a period of time; then let the reactor cool down with the furnace; take out the nickel sheet;

[0028] 3. Wash the nickel sheet repeatedly with absolute ethanol and deionized water, then put it in a drying oven at 60°C to dry, and finally get a dried nickel sheet; the final NiTe is formed on the surface of the nickel sheet 2 Materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com