Preparation method of fluorine-containing adhesive for lithium battery ceramic diaphragm and ceramic diaphragm prepared by using the adhesive

A technology of ceramic diaphragm and lithium battery, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of affecting the coating speed, product leveling, affecting the microscopic morphology of ceramic diaphragm, and harmful to the environment of the adhesive. Achieve excellent water repellency, excellent processability, heat resistance and improved solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the adhesive used for the lithium-ion battery ceramic diaphragm is: 18.6g of trifluoroethyl methacrylate calculated by weight percentage, 2.4g of hydroxyethyl methacrylate, 7.2g of acrylic acid, 13.5g of styrene g, emulsifier allyloxy nonylphenol propanol polyoxyethylene (4) ether ammonium sulfate 0.6g, sodium hydroxide 3.9g, ammonium persulfate 0.2g and water 140g are all added to the pre-emulsification reaction container, mechanically stirred for 3h Disperse to form a stable pre-emulsion; take 120g of the pre-emulsion and add it to the polymerization reaction vessel, heat it to the polymerization reaction temperature of 70°C under the protection of nitrogen, react for 20 minutes, then add the remaining pre-emulsion dropwise, drop it within 1 hour, and keep it warm for 3 hours , cooled to room temperature, and filtered to obtain a binder emulsion for lithium battery ceramic separators.

[0031] The prepared ceramic diaphragm adhesive emulsion ...

Embodiment 2

[0033] In this embodiment, trifluoroethyl acrylate is used as the adhesive for the ceramic diaphragm instead of trifluoroethyl methacrylate, the amount of water is increased from 140 g to 180 g, and the rest of the steps are the same as in Embodiment 1.

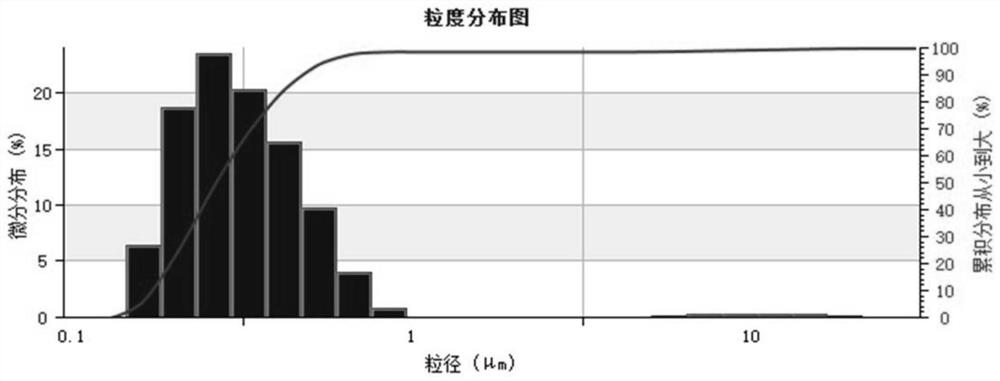

[0034] The prepared ceramic diaphragm adhesive emulsion is white, with a solid content of about 20%, a viscosity of less than 200 centipoise, and a copolymer particle size D50 of less than 0.5 μm. The obtained adhesive particle size distribution spectrum is as follows: figure 2 shown.

Embodiment 3

[0036] In this embodiment, the ceramic diaphragm adhesive uses hydroxyethyl acrylate instead of hydroxyethyl methacrylate, and the emulsifier allyloxy fatty alcohol oxyethylene ether ammonium sulfate replaces allyloxy nonylphenol propanol polyoxyethylene ( 4) ether ammonium sulfate, and consumption is brought up to 0.8g by 0.6g, and potassium persulfate replaces ammonium persulfate, and the consumption of water is reduced to 100g by 140g, and all the other steps are with embodiment 1.

[0037] The prepared ceramic diaphragm binder emulsion is milky white, has a solid content of about 30 percent, a viscosity of less than 600 centipoise, and a copolymer particle diameter D50 of less than 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com