Production method capable of preventing rubber tree wood flour from being corroded by moths through physical method

A technology of production method and physical method, applied in the direction of wood treatment, wood heating, wood processing equipment, etc., can solve the problem of long soaking time, etc., to prevent drying, reduce drying cycle and drying cost, omit equipment and anti-corrosion treatment process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

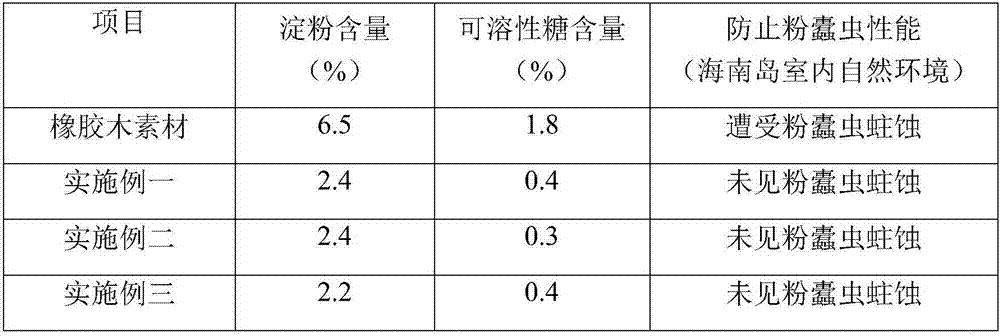

Embodiment 1

[0068] 1) Saw small rubber wood logs into small-sized lumber as raw material for glulam finger-jointed boards. The thickness of the board is 2.5cm, the length of the board is 40cm, 50cm, 60cm, 70cm, 80cm, and the width of the board is 4.5cm. 5.5cm, 6.5cm, 7.5cm;

[0069] 2) Stack the plates and counterweight them, and dry them in air;

[0070] 3) Put the wood into a high-temperature hydrothermal treatment kiln, start heating, and pass in steam. When the temperature is below 95°C, keep the dry bulb and wet bulb to heat up synchronously. The air window is slightly opened, so that the excess moisture released by the wood can be naturally dissipated through the gap of the exhaust window. Keep it for 2 days. When the moisture content of the wood is lower than 15%, the temperature is lowered to 80°C, and the humidity balance treatment is completed until the moisture content of the wood is 12%. , the kiln temperature is lower than 45°C, and the kiln is taken out.

[0071] 4) Detect...

Embodiment 2

[0073] 1) Saw rubber wood logs into natural boards and imperial standard lumber as raw materials for the production of solid wood furniture. The thickness of natural boards is 2.5cm, 3.5cm, length 2m, the width of the small head is greater than 10cm, and the thickness of imperial standard lumber is 2.5cm cm, 3.5cm, plate length 1-1.3m, plate width less than 10.5cm;

[0074] 2) Stack the plates and counterweight them, and dry them in air;

[0075] 3) Put the wood into a high-temperature hydrothermal treatment kiln, start heating, and feed steam. When the temperature is below 95°C, keep the dry bulb and wet bulb warming up synchronously. When the temperature of the dry bulb rises to 121°C, keep heating but stop feeding steam The air window is slightly opened, so that the excess moisture released by the wood can be dissipated naturally through the gap of the exhaust window. The moisture content of the wood is reduced to 35%, and the temperature is reduced to 115°C. After the mois...

Embodiment 3

[0078] 1) Saw rubber wood logs into natural boards and imperial standard timbers as raw materials for the production of solid wood furniture. The thickness of natural boards is 4.5cm, 5.5cm, length 2m, the width of the small end is greater than 12cm, and the thickness of imperial standard timbers is 4.5cm. cm, 5.5cm, plate length 1-1.3m, plate width less than 10.5cm;

[0079] 2) Stack the plates and counterweight them, and dry them in air;

[0080] 3) Put the wood into a high-temperature hydrothermal treatment kiln, start heating, and feed steam. When the temperature is below 95°C, keep the dry bulb and wet bulb warming up synchronously. When the temperature of the dry bulb rises to 117°C, keep heating but stop feeding steam The air window is slightly opened, so that the excess moisture released by the wood can be naturally dissipated through the gap of the exhaust window. The moisture content of the wood is reduced to 40%, and the temperature is reduced to 110°C. After the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com