Repairing material for heavy metal polluted soil and application method of repairing material

A technology for repairing materials and polluted soil, applied in the field of environmental protection, can solve problems such as complicated preparation process of repairing materials, affecting soil planting function, long degradation cycle, etc., achieves broad application prospects and practical value, and is easy for large-scale industrial production and promotion application, long-term stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

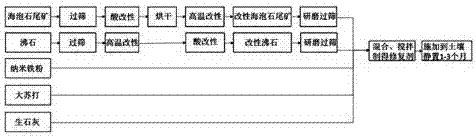

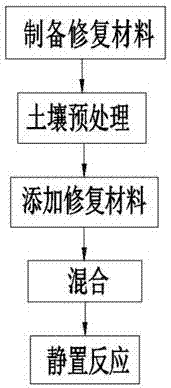

[0059] A repairing agent for heavy metal polluted soil, comprising: modified zeolite, modified sepiolite, nanometer iron powder, soda, and quicklime. Sepiolite tailings were purchased from Yuanyuan Sepiolite Company in Xiangtan County, Hunan Province. The main components of sepiolite tailings were: SiO2 66.28%, CaO 9.80%, MgO 8.74%, Fe2O3 1.81%, Al2O3 2.72%.

[0060] First prepare the modified zeolite, then prepare the modified sepiolite, then mix 7 parts of modified zeolite, 30 parts of modified sepiolite tailings, 13 parts of nano-iron powder, and 5 parts of soda Mix evenly with 45 parts of quicklime.

[0061] Wherein, the modified zeolite is prepared according to the sequence of first thermal modification and then acid modification, and the specific modification steps are as follows:

[0062] a, pretreatment, the natural zeolite is naturally dried, and sieved through a 20-mesh sieve to obtain a zeolite pretreatment product;

[0063] b, thermal modification, the zeolite af...

Embodiment 2

[0081] First prepare the modified zeolite, then prepare the modified sepiolite, then prepare 3 parts of modified zeolite, 30 parts of modified sepiolite tailings, 14 parts of nano-iron powder, and 3 parts of soda Mix evenly with 50 parts of quicklime.

[0082] Wherein, the modified zeolite is prepared according to the sequence of first thermal modification and then acid modification, and the specific modification steps are as follows:

[0083] a, pretreatment, the natural zeolite is naturally dried, and sieved through a 20-mesh sieve to obtain a zeolite pretreatment product;

[0084] b, thermal modification, the zeolite after sieving is subjected to heat treatment, the thermal modification temperature is 450°C, the thermal modification is 3h, and put into a desiccator to cool;

[0085] c, Acid modification, adding a concentration of 0.5mol / L hydrochloric acid solution to the above-mentioned cooled zeolite, the solid-to-liquid ratio is 1g: 5mL, soaking and stirring at room tem...

Embodiment 3

[0094] Prepare modified zeolite first, then prepare modified sepiolite, then prepare 6 parts of modified zeolite, 35 parts of modified sepiolite tailings, 8 parts of nano-iron powder, and 3 parts of soda Mix evenly with 48 parts of quicklime.

[0095] Wherein, the modified zeolite is prepared according to the sequence of first thermal modification and then acid modification, and the specific modification steps are as follows:

[0096] a, pretreatment, the natural zeolite is naturally dried, and sieved through a 20-mesh sieve to obtain a zeolite pretreatment product;

[0097] b, thermal modification, the zeolite after sieving is subjected to heat treatment, the thermal modification temperature is 500°C, the thermal modification is 2h, and put into a desiccator to cool;

[0098] c, Acid modification, add a concentration of 0.5mol / L nitric acid solution to the above cooled zeolite, the solid-to-liquid ratio is 1g: 5mL, soak and stir at room temperature for 10h, supplemented with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com