A transport bed methanation catalyst, a preparing method thereof and applications of the catalyst

A catalyst, bed methane technology, used in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. The effect of improved strength and wear resistance, good flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

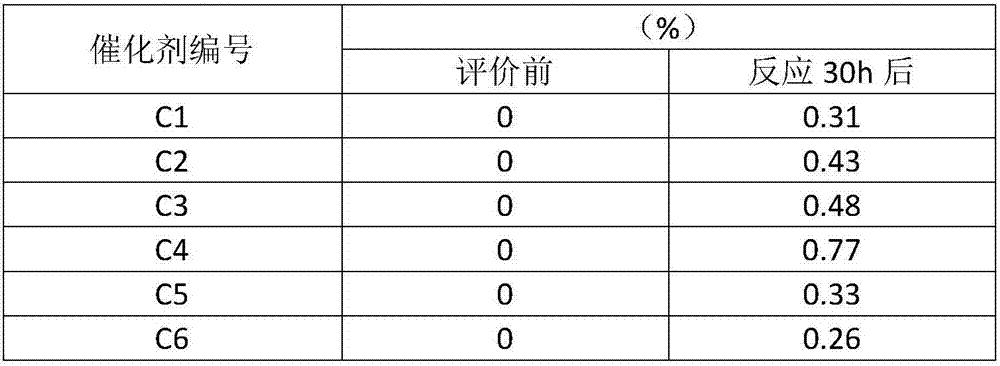

Examples

Embodiment 1

[0028] The specific preparation process of the catalyst of this embodiment is as follows:

[0029] 1) 88.80 grams of Mg(NO 3 ) 2 ·6H 2 O, 14.07 g Zr(NO 3 ) 4 ·5H 2 O, 80.96 g Ni(NO 3 ) 2 ·6H 2 O (AR grade) mixed with 100ml deionized water to make a solution;

[0030] 2) 50 g of α-Al with a particle size distribution of 20-180 μm after roasting treatment 2 o 3 The microspheres were immersed in the above solution and placed in a water bath at 40°C for 2 hours;

[0031] 3) The solution prepared in step 2) was separated by filtration, and the obtained particles were dried at 80° C. for 12 hours.

[0032] 4) The particles obtained in step (3) were calcined at 600° C. for 6 hours to obtain the catalyst of this example.

[0033] Among them, α-Al 2 o 3 The microspheres were calcined at 900°C for 6h in advance.

[0034] The catalyst prepared in this embodiment consists of: 15 parts of NiO, 1 part of ZrO 2 , 5 parts of MgO and 79 parts of Al 2 o 3 , recorded as C1.

Embodiment 2

[0036] The specific preparation process of the catalyst of this embodiment is as follows:

[0037] 1) 85.50 grams of Mg(NO 3 ) 2 ·6H 2 O, 33.78 g Ce(NO 3 ) 3 ·6H 2O (AR grade), 77.88 grams of Ni (NO 3 ) 2 ·6H 2 O mixed and added to 100ml deionized water to make a solution.

[0038] 2) 50 g of α-Al with a particle size distribution of 30-170 μm after roasting treatment 2 o 3 The microspheres were immersed in the above solution and placed in a water bath at 60°C for 2.5 hours;

[0039] 3) The solution prepared in step 2) was separated by filtration, and the obtained particles were dried at 100° C. for 8 hours.

[0040] 4) The particles obtained in step 3) were calcined at 700° C. for 6 hours to obtain the catalyst of this example.

[0041] Among them, α-Al 2 o 3 The microspheres were pre-calcined at 1000 °C for 5 h.

[0042] The catalyst prepared in this embodiment consists of: 15 parts of NiO, 5 parts of CeO 2 , 5 parts of MgO and 75 parts of Al 2 o 3 , record...

Embodiment 3

[0044] The specific preparation process of the catalyst of this embodiment is as follows:

[0045] 1) 88.84 grams of Mg(NO 3 ) 2 ·6H 2 O, 36.88 g La(NO 3 ) 3 (AR grade), 96g Ni(NO 3 ) 2 ·6H 2 O mixed and added to 100ml deionized water to form a solution;

[0046] 2) 50 g of α-Al with a particle size distribution of 50-160 μm after roasting treatment 2 o 3 The microspheres were immersed in the above solution and placed in a water bath at 70°C for 3.5 hours;

[0047] 3) The solution prepared in step 2) was separated by filtration, and the obtained particles were dried at 110° C. for 10 h;

[0048] 4) The particles obtained in step 3) were calcined at 600° C. for 6 hours to obtain the catalyst of this example.

[0049] Among them, α-Al 2 o 3 The microspheres were pre-calcined at 1100 °C for 4 h.

[0050] The catalyst prepared in this embodiment consists of: 18 parts of NiO, 5 parts of La 2 o 3 , 5 parts of MgO and 72 parts of Al 2 o 3 , recorded as C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com