Method for preparing bone-like structure film layer on surface of titanium

A structural membrane and bone-like technology, applied in the field of biomedical materials, can solve the problems of inability to form a three-dimensional structure, unfavorable protein adhesion, bone cell adhesion and proliferation, prolonged osseointegration, etc., and achieves excellent results in contact angle and surface energy measurement data. , Low production cost, uniform shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing an osteoid structure film layer on a titanium surface, comprising the following steps:

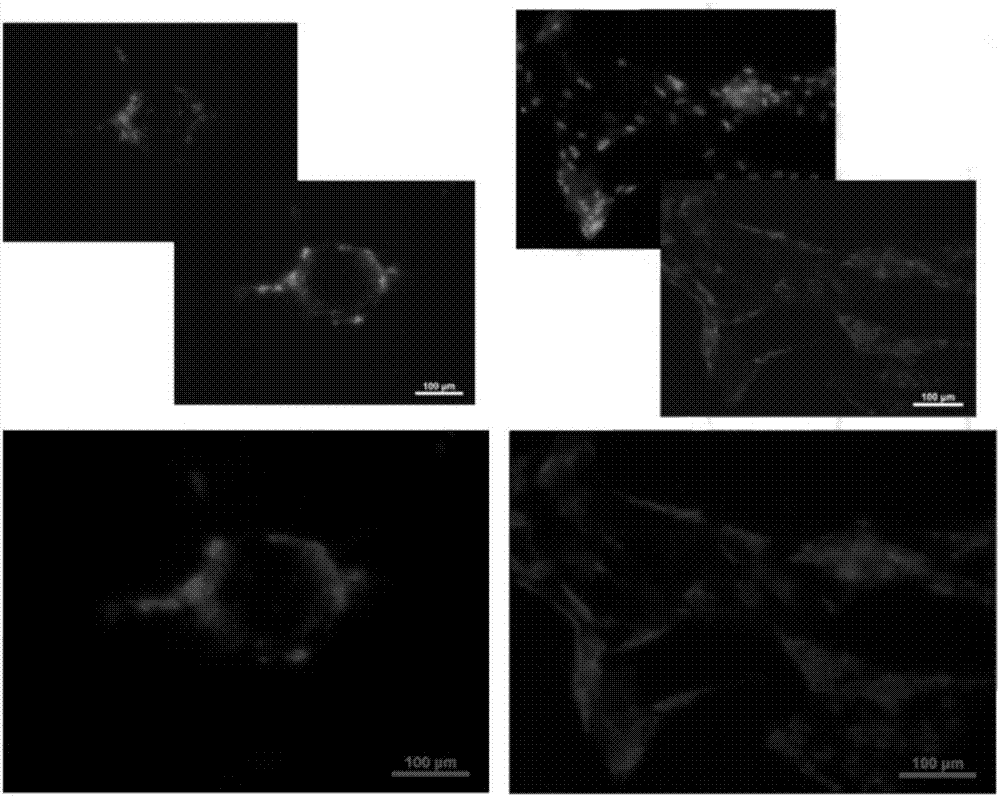

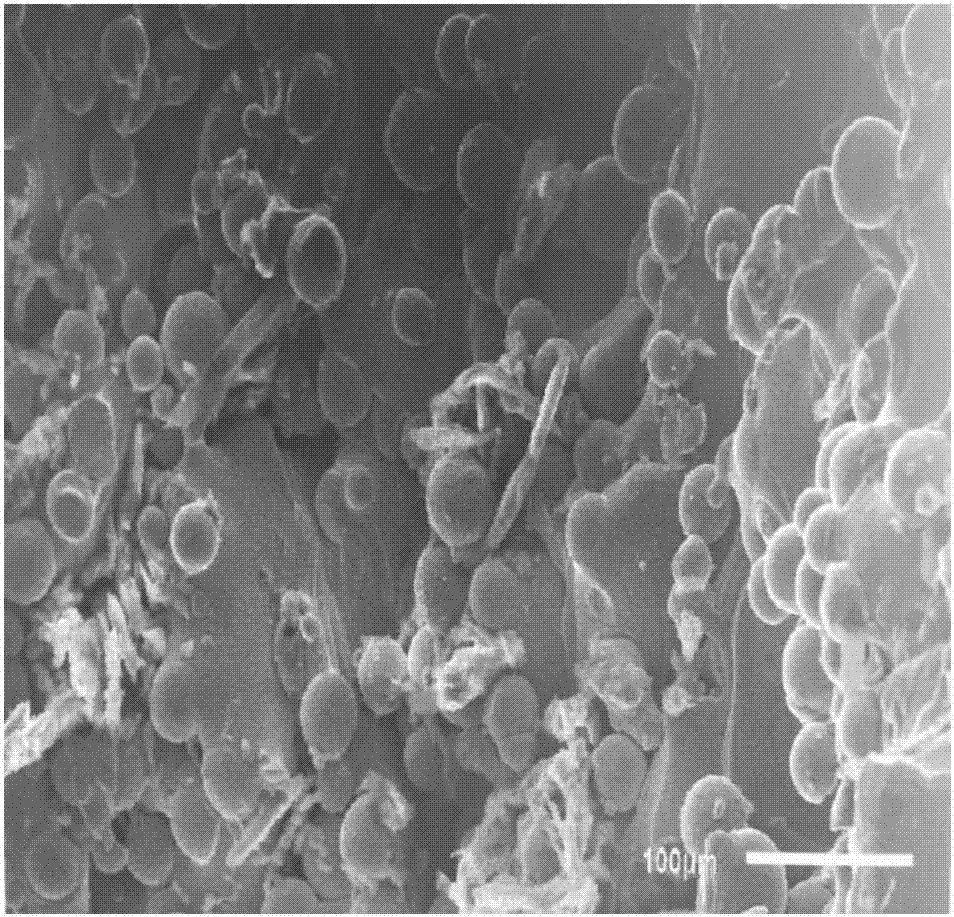

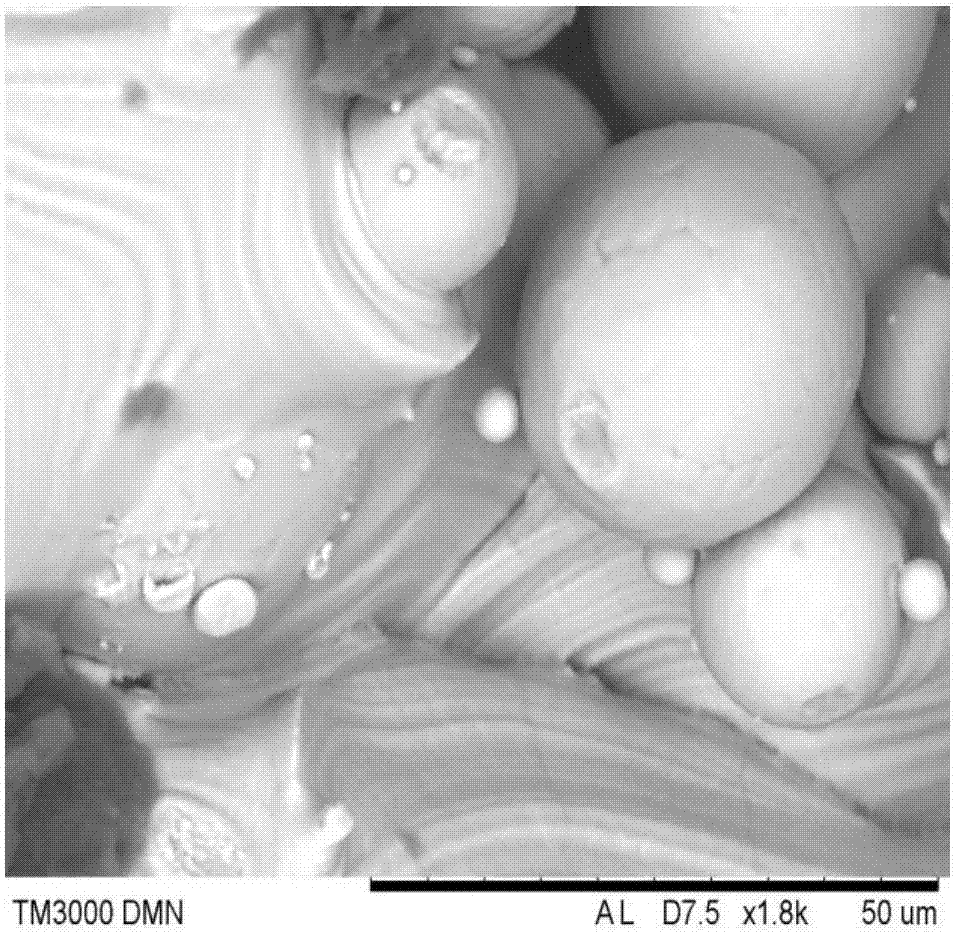

[0040] a. Pretreatment: 3D printing laser casting technology is used to form a smooth spherical structure on the surface of medical titanium metal, which makes the surface of medical titanium metal rough. The diameter of the spherical structure is 20-50 μm, and the distance between the pits on the surface is 100-300 μm. After repeated washing with high-pressure water, ultrasonic oscillation was performed for 30 minutes, and dried for later use.

[0041] b. Electrochemical treatment: the pretreated medical titanium metal is used as the anode, and the copper sheet is used as the cathode, which is placed in the electrolyte solution and anodized by a DC stabilized power supply. The anodic oxidation current is 100mA, and the distance between the two electrodes is 25mm. Electrolyzed for 2 hours, a titanium dioxide-like periosteum layer was formed on the surface; the...

Embodiment 2

[0062] A method for preparing an osteoid structure film layer on a titanium surface, comprising the following steps:

[0063] a. Pretreatment: 3D printing laser casting technology is used to form a smooth spherical structure on the surface of medical titanium metal, which makes the surface of medical titanium metal rough. The diameter of the spherical structure is 20-50 μm, and the distance between the pits on the surface is 100-300 μm. Then use high-pressure water to wash repeatedly, perform ultrasonic oscillation for 20 minutes, and dry it for later use.

[0064] b. Electrochemical treatment: the pretreated medical titanium metal is used as the anode, and the copper sheet is used as the cathode, which is placed in the electrolyte solution and anodized by a DC stabilized power supply. The anodic oxidation current is 80mA, and the distance between the two electrodes is 22mm. After electrolysis for 3 hours, a titanium dioxide-like periosteum layer was formed on the surface; the...

Embodiment 3

[0068] A method for preparing an osteoid structure film layer on a titanium surface, comprising the following steps:

[0069] a. Pretreatment: 3D printing laser casting technology is used to form a smooth spherical structure on the surface of medical titanium metal, which makes the surface of medical titanium metal rough. The diameter of the spherical structure is 20-50 μm, and the distance between the pits on the surface is 100-300 μm. After repeated washing with high-pressure water, ultrasonic oscillation was performed for 40 minutes, and then dried for later use.

[0070] b. Electrochemical treatment: the pretreated medical titanium metal is used as the anode, and the copper sheet is used as the cathode, which is placed in the electrolyte solution, and the anodic oxidation is performed by a DC stabilized power supply. The anodic oxidation current is 120mA, and the distance between the two electrodes is 30mm. After 4 hours of electrolysis, a titanium dioxide-like periosteum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com