Preparation method of copper oxidechemically modified electrode for detecting glucose

A technology of chemical modification and copper oxide, applied in electrochemical variables of materials, measuring devices, scientific instruments, etc., can solve the problems of poor consistency of quality and performance, complicated operation, easy environmental pollution, etc., and achieve strong vertical charge transfer. Ability, mild process conditions, the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

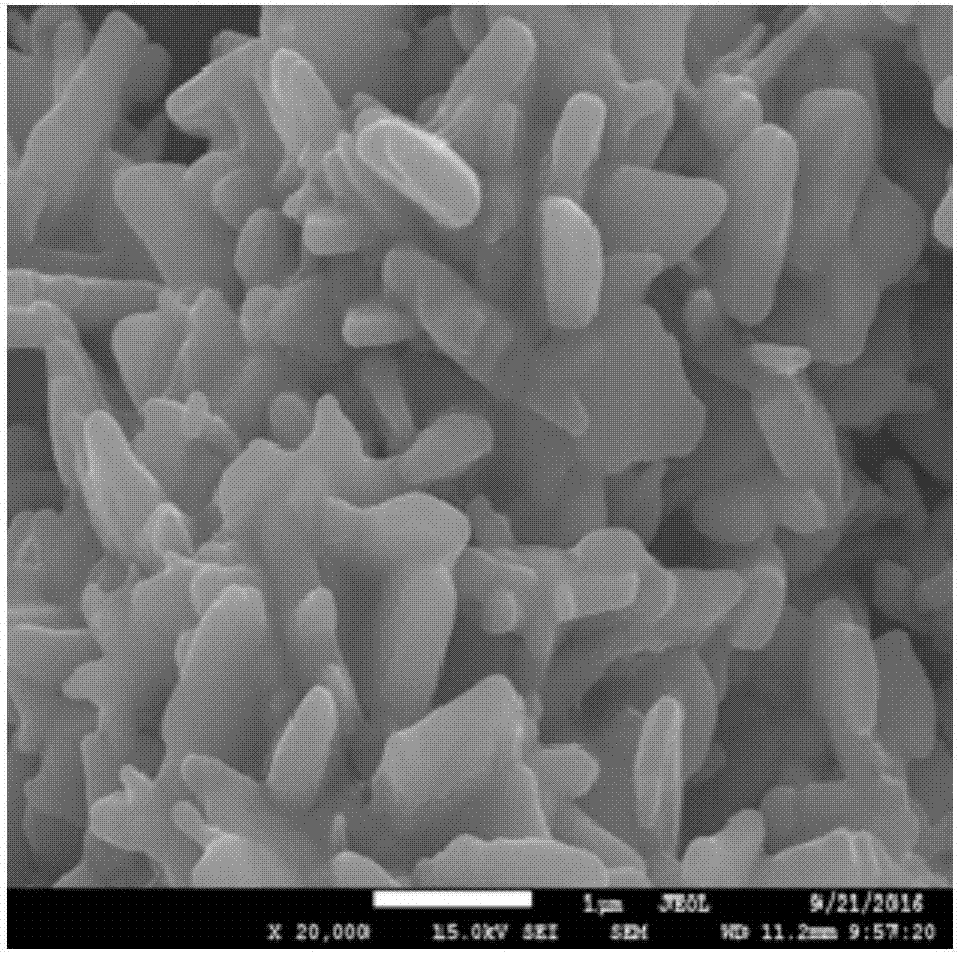

[0038] A preparation method for a copper oxide chemically modified electrode for detecting glucose, the steps of which are:

[0039] A. Adding Cu(NO 3 ) 2 Prepare 1.0mol / L of Cu(NO 3 ) 2 solution, prepare urea into 1.0mol / L urea solution; then Cu(NO 3 ) 2 The solution is slowly added dropwise to the urea solution, and then stirred for 20 minutes to obtain a mixed solution; the molar ratio of copper salt to urea in the mixed solution is 3:2;

[0040] B. Pour the mixed solution obtained in step A into a hydrothermal reaction kettle, and perform a hydrothermal reaction at a temperature of 130° C. for 5 hours; then suction filter to obtain a solid product, then wash and dry;

[0041] C. Put the solid product of step B into a muffle furnace, calcine and decompose, then cool down naturally, and grind to obtain copper oxide powder;

[0042] In this example, the heating rate of the calcination decomposition is 5° C. / min, the calcination temperature is 450° C., and the calcinatio...

Embodiment 2

[0053] A preparation method for a copper oxide chemically modified electrode for detecting glucose, the steps of which are:

[0054] A. Add CuSO 4 Prepare 1.0mol / L CuSO 4 solution, the urea was formulated into 8mol / L urea solution; then the CuSO 4 The solution is slowly added dropwise to the urea solution, and then stirred for 60 minutes to obtain a mixed solution; the molar ratio of copper salt to urea in the mixed solution is 3:2;

[0055] B. Pour the mixed solution obtained in step A into a hydrothermal reaction kettle, and perform a hydrothermal reaction at a temperature of 200° C. for 0.5 hours; then suction filter to obtain a solid product, then wash and dry;

[0056] C. Put the solid product of step B into a muffle furnace, calcine and decompose, then cool down naturally, and grind to obtain copper oxide powder;

[0057] In this example, the heating rate of the calcination decomposition is 1° C. / min, the calcination temperature is 220° C., and the calcination time is...

Embodiment 3

[0062] A preparation method for a copper oxide chemically modified electrode for detecting glucose, the steps of which are:

[0063] A. CuCl 2 Prepare 1.5mol / L CuCl 2 Solution, prepare urea into 0.1mol / L urea solution; then CuCl 2 The solution is slowly added dropwise to the urea solution, and then stirred for 5 minutes to obtain a mixed solution; the molar ratio of copper salt to urea in the mixed solution is 3:2;

[0064] B. Pour the mixed solution obtained in step A into a hydrothermal reaction kettle, and perform a hydrothermal reaction at a temperature of 100° C. for 12 hours; then suction filter to obtain a solid product, then wash and dry;

[0065] C. Put the solid product of step B into a muffle furnace, calcine and decompose, then cool down naturally, and grind to obtain copper oxide powder;

[0066] In this example, the heating rate of the calcination decomposition is 20° C. / min, the calcination temperature is 600° C., and the calcination time is 0.5 hour.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com