Illumination lamp and preparation method thereof

A lighting fixture, one-sided technology, applied in lighting and heating equipment, lighting devices, components of lighting devices, etc., can solve the problems of large radiators, large size of lamps, inconvenient use, etc., and reduce the volume of heat dissipation and heat transfer channels. The effect of unblocking and reducing the temperature of lamps and lanterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, lighting fixture and preparation method thereof

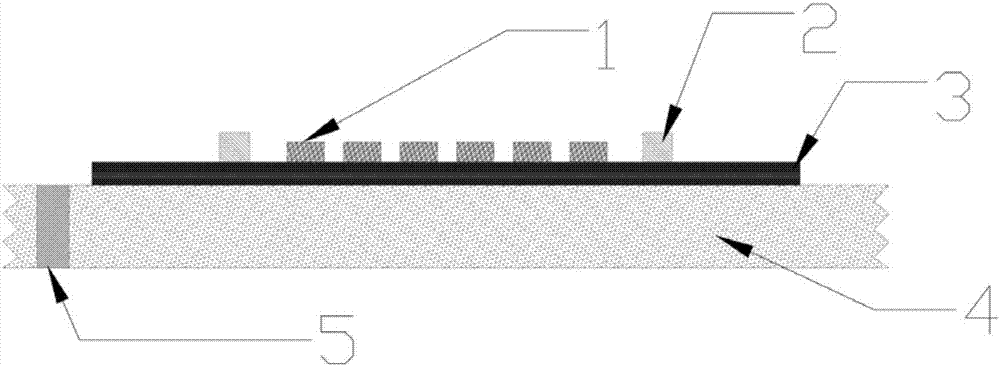

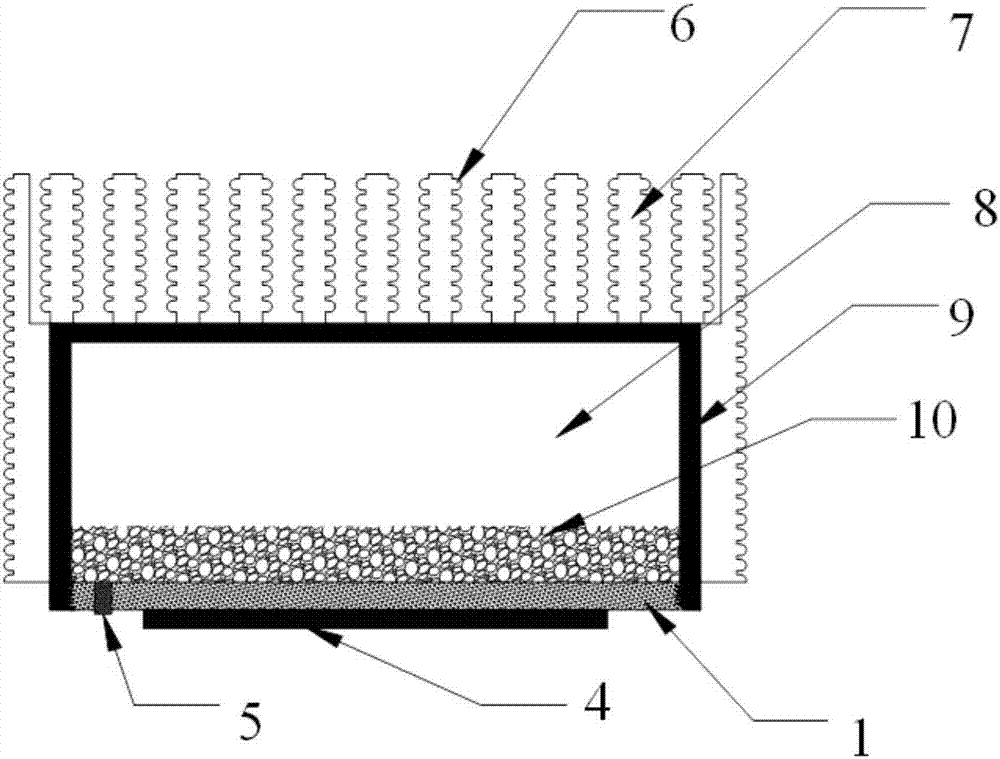

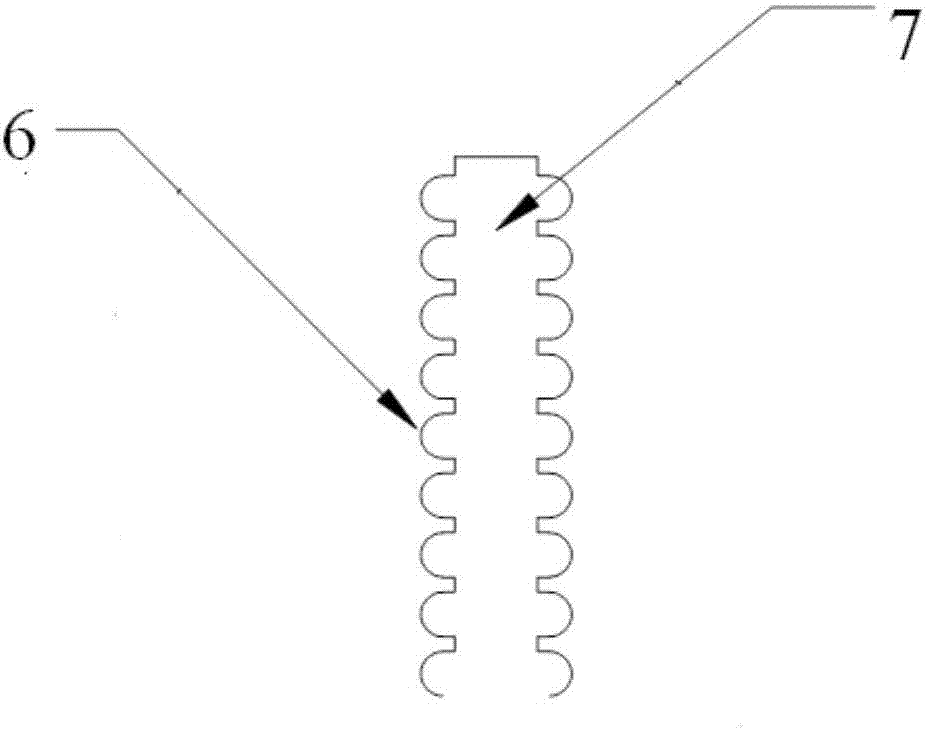

[0063] Such as Figure 1-3 As shown, the lighting fixture provided by the present invention includes an LED light-emitting integrated light source and a micro-groove group phase-change fin radiator; an LED light-emitting integrated light source includes an LED light source 1 and a radiator vapor chamber 4; the LED light source 1 is arranged on On one side of the radiator vapor chamber 4; the microgroove group phase change fin radiator includes a phase change liquid 10, a cavity 8 (in a vacuum state) and cooling fins 7; the cavity 8 has an opening, and the LED light source 1 is opposite The other side of the heat radiator vapor chamber 4 seals the opening; a plurality of cooling fins 7 are arranged on the outer cavity wall 9 of the cavity 8, and a plurality of microgroove groups 6 are arranged on the cooling fins 7, and a phase change liquid 10 (specifically adopts Distilled water) is placed inside the cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com