Coloring agent for outer layer nylon fabrics of outdoor sport functional garments

A functional technology for nylon fabrics, applied in dyeing methods, textiles, and papermaking. It can solve the problems of unsuitable dyeing agents and fading, and achieve the effects of meeting dyeing requirements, easy coloring, and excellent waterproof and breathable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

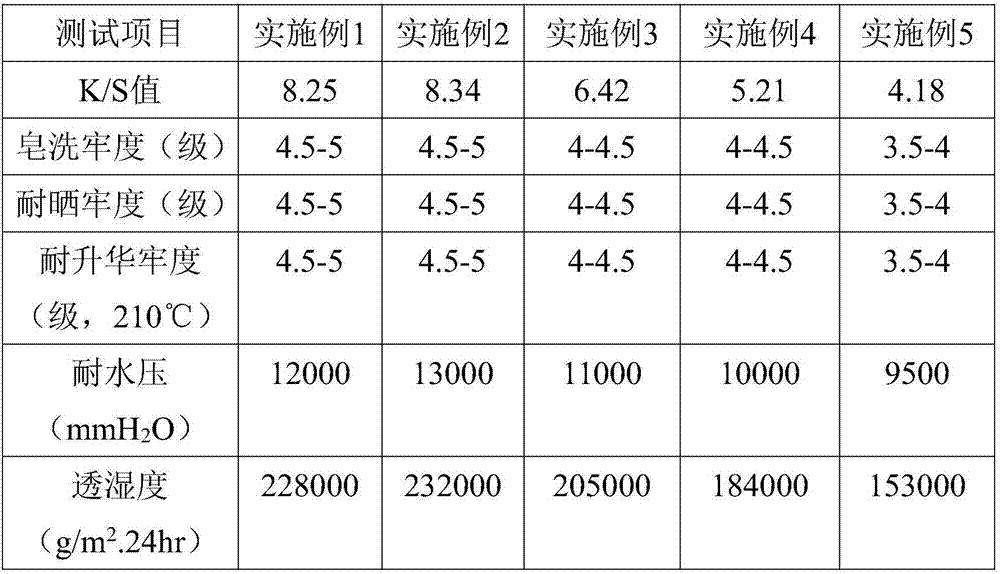

Examples

Embodiment 1

[0021] (1) Add 5 parts of polyethylene oxide and 5 parts of polyvinyl chloride paste resin to 100 parts of water, heat to reflux state and keep mixing for 25 minutes, then add 4 parts of terpene resin and 1 part of epoxy soybean oil, continue to reflux and keep mixing 15min, to obtain material I;

[0022] (2) Add 2 parts of polytetrafluoroethylene and 1 part of hydrogenated castor oil to 10 parts of polyvinyl alcohol resin, heat to 120-125 ° C and mix for 30 minutes, then add 0.5 parts of polydimethyldiallylammonium chloride and 0.5 parts of dicyclohexylcarbodiimide, and continue to mix at 120-125°C for 10 minutes to obtain material II;

[0023] (3) Add 5 parts of organic dyes, 3 parts of crospovidone and 2 parts of poloxamer to material I, and heat to reflux state and mix for 10 minutes, then add material II, 2 parts of nano talcum powder, 2 parts of Lauryl alcohol polyoxyethylene ether and 0.5 part of cationic polyacrylamide were continuously mixed under reflux for 15 minut...

Embodiment 2

[0027] (1) Add 8 parts of polyethylene oxide and 4 parts of polyvinyl chloride paste resin to 100 parts of water, heat to reflux state and mix for 25 minutes, then add 4 parts of terpene resin and 1 part of epoxidized soybean oil, continue to reflux and mix 15min, to obtain material I;

[0028] (2) Add 2 parts of polytetrafluoroethylene and 1 part of hydrogenated castor oil to 10 parts of polyvinyl alcohol resin, heat to 120-125 ° C and mix for 30 minutes, then add 1 part of polydimethyldiallylammonium chloride and 0.5 parts of dicyclohexylcarbodiimide, and continue to mix at 120-125°C for 10 minutes to obtain material II;

[0029] (3) Add 5 parts of organic dyes, 3 parts of crospovidone and 3 parts of poloxamer to material I, and heat to reflux state and mix for 10 minutes, then add material II, 2 parts of nano talcum powder, 1 part of Lauryl alcohol polyoxyethylene ether and 1 part of cationic polyacrylamide were continuously refluxed and kept mixed for 15 minutes, and the ...

Embodiment 3

[0033] (1) Add 8 parts of polyethylene oxide and 4 parts of polyvinyl chloride paste resin to 100 parts of water, heat to reflux state and mix for 25 minutes, then add 4 parts of terpene resin and 1 part of epoxidized soybean oil, continue to reflux and mix 15min, to obtain material I;

[0034] (2) Add 2 parts of polytetrafluoroethylene and 1 part of hydrogenated castor oil to 10 parts of polyvinyl alcohol resin, heat to 120-125 ° C and mix for 30 minutes, then add 1 part of polydimethyldiallylammonium chloride and 0.5 parts of dicyclohexylcarbodiimide, and continue to mix at 120-125°C for 10 minutes to obtain material II;

[0035] (3) Add 5 parts of organic dyes, 3 parts of crospovidone and 3 parts of poloxamer to material I, and heat to reflux state and mix for 10 minutes, then add material II, 2 parts of nano talcum powder, 1 part of Lauryl alcohol polyoxyethylene ether and 1 part of cationic polyacrylamide were continuously refluxed and kept mixed for 15 minutes, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com