Dyeing method of calcium alginate fiber

A technology of calcium alginate fiber and dyeing method, which is applied in the field of fiber dyeing, and can solve the problems of few types of dyes, complicated dyeing process, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

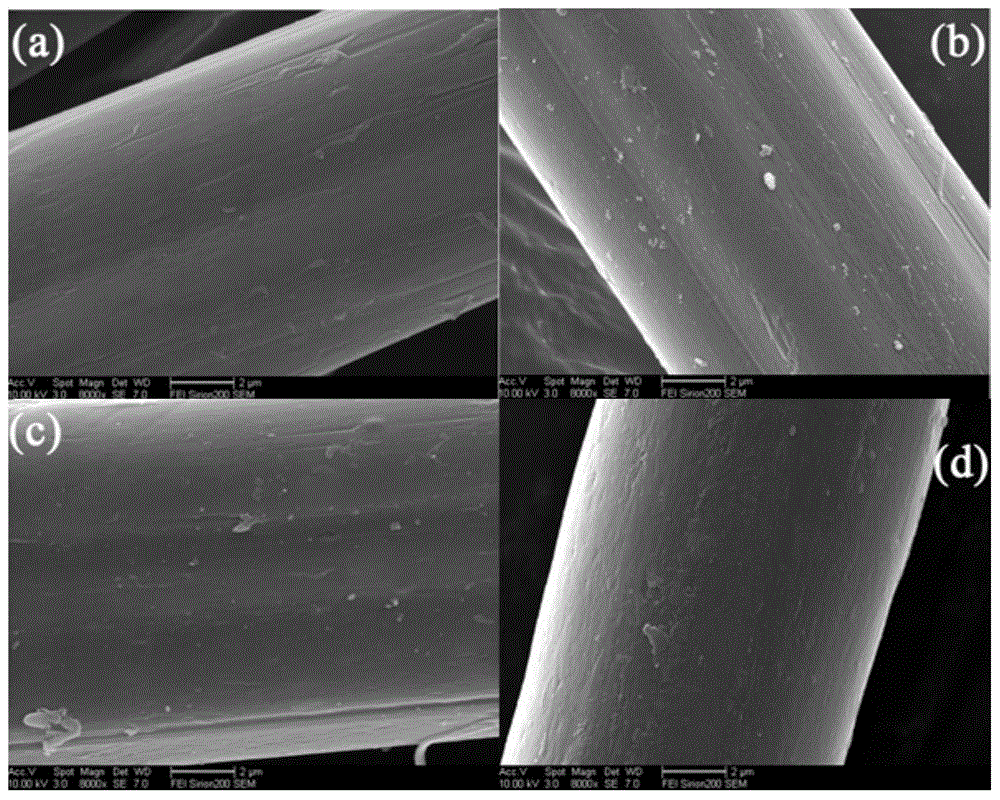

Image

Examples

Embodiment 1

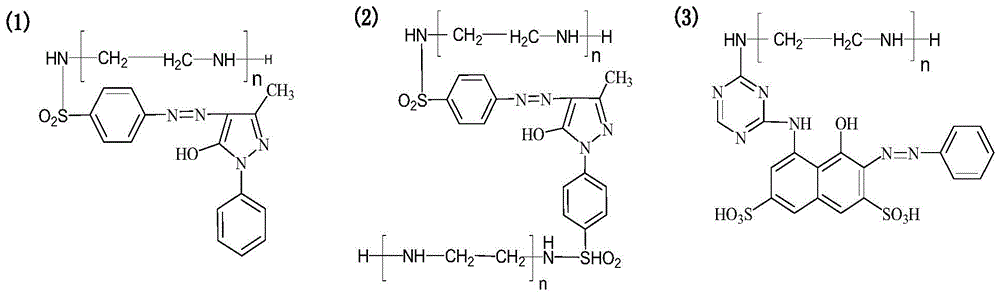

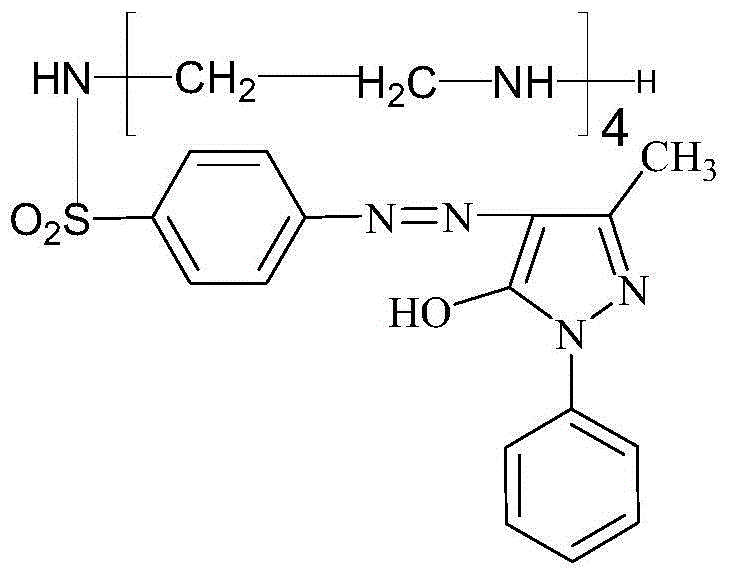

[0025] The dye Y-1 structure used is shown below:

[0026]

[0027] Weigh 0.5 g of dye Y-1 and dissolve it in 500 g of water to prepare the dye solution. Then use 5% hydrochloric acid solution to adjust the pH value of the dye solution to 4.5. Put 25 grams of calcium alginate fibers in the dyeing solution, raise the temperature of the dyeing solution to 40° C., and then dye for 50 minutes. After dyeing, take out the fiber and soak it in a neutral soap solution containing 4‰ at 95°C for 10 minutes. After taking out the fiber, wash it fully and dry it in the air.

Embodiment 2

[0029] The structure of the dye Y-2 used is described below:

[0030]

[0031] Weigh 0.5 g of dye Y-2 and dissolve it in 800 g of water to prepare the dye solution. Then use 5% hydrochloric acid solution to adjust the pH value of the dye solution to 3.5. Put 50 grams of calcium alginate fibers in the dyeing solution, raise the temperature of the dyeing solution to 30°C, and then dye for 30 minutes. After dyeing, take out the fiber and soak it in a neutral soap solution containing 4‰ at 95°C for 10 minutes. After taking out the fiber, wash it fully and dry it in the air.

Embodiment 3

[0033] The structure of the dye R-1 used is described below:

[0034]

[0035] Weigh 0.5 g of dye R-1 and dissolve it in 800 g of water to prepare the dye solution. Then use 5% hydrochloric acid solution to adjust the pH value of the dye solution to 5. Put 50 grams of calcium alginate fibers in the dyeing solution, raise the temperature of the dyeing solution to 50°C, and then dye for 50 minutes. After dyeing, take out the fiber and soak it in a neutral soap solution containing 4‰ at 95°C for 10 minutes. After taking out the fiber, wash it fully and dry it in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com