Bulk yarn processing device and method

A processing device and technology of bulked yarn, which is applied in the direction of yarn, spinning machine, textile and paper making, etc. It can solve the problems of uneven yarn bulking, inconsistent density, inconsistent yarn shrinkage ratio, and inadaptability to environmental protection requirements. Uniform distribution to avoid different effects of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

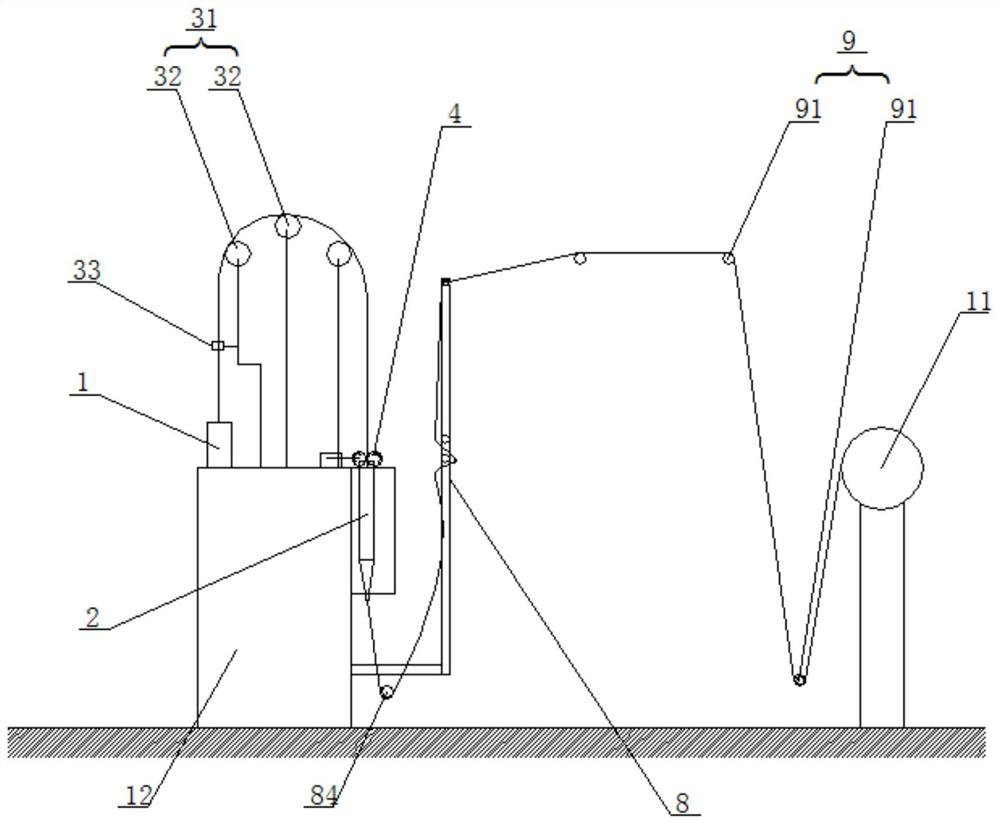

[0095] like Figure 1-2 Show, this embodiment provides a vertical yarn puff device, including the storage veil 1, the velvery device 2, and heating device for heating for the heating of the velvet device 7, the gauze delivery mechanism 3, the tube gauze rolling equipment 11 equipment 11 Dyeing equipment: also includes supporting rack 12, the storage veil 1, the velvery device 2. The gauze delivery mechanism 3 is connected to the support frame 12; specific:

[0096] The storage yarn 1 is used to store yarn 13, and the yarn 13 is a tube gauze;

[0097] The velvery device 2, the veteran vessel device is equipped with a vertical chamber for bullets to push; in this embodiment, the velvet device 2 includes the external in the first cavity 21 and the first cavity 21 of the first cavity 21 The form of expression can be round tube, internal and external tube. One end of the first cavity 21 is equipped with a yarn 22. The other end of the first cavity 21 is connected to the cone -shaped cav...

Embodiment 2

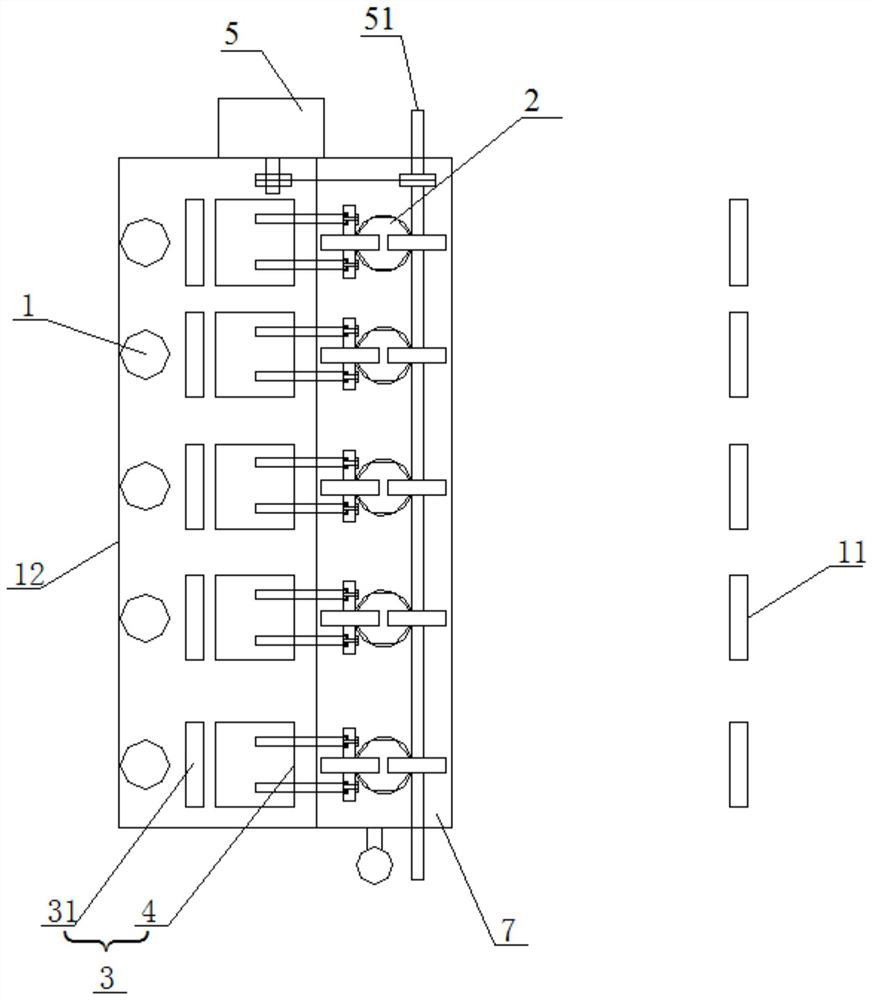

[0109] Regarding the driver agency, the driver includes active wheel components 41 and the slave wheel component 42, the driver's agency 52 and the rotation of the Angle wheel 62 will be sandwiched to the yarn between the active wheel 52 and the velvet 62 to enter to the entry to the entry to the inlet Towel 22.

[0110] In this embodiment, the active wheel component 41 includes the active axis 51 connected to the power device 5 and the set of the active wheel 52 set on the active axis 51. Transmission. The fixed rod 61 extended from the cylinder 6, the expansion and contraction self -cylinder 6, the connection shaft 64 connected to the fixed rod 61 (e.g., the connection shaft 64 set is set on the fixed rod 61 to implement the connection) and the rotation connection connection From the slave wheel 62 on the connection axis 64, the cylinder 6 can control the expansion of the fixed rod 61 to adjust the spacing of the active wheel 52 to the slave wheel 62. In addition, such as Figure...

Embodiment 3

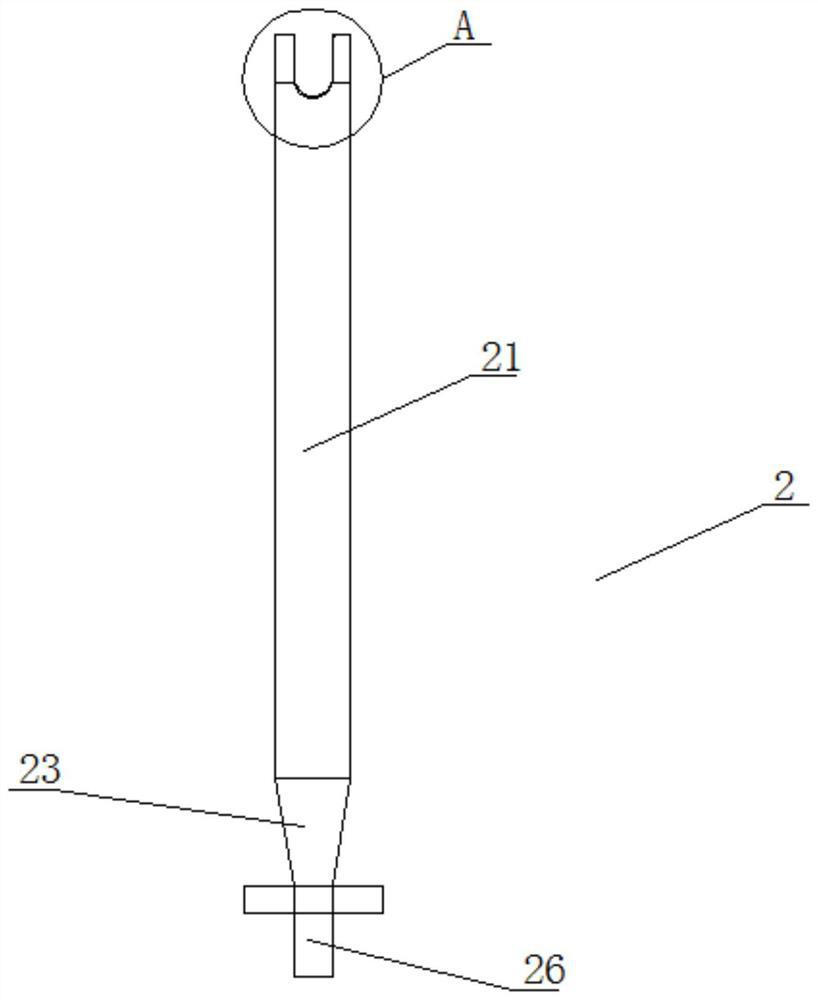

[0113] About heating device 7, such as Figure 10 Show, heating device 7 includes a diversion pipe 72, the first shell 71, and the velvet device 2 in the first shell 71; 71; Specifically, the first cavity 21 is cylindrical, which is provided with an external thread in the outer wall of the first cavity 21. 24 Connection with a gauze tube 26, and the veil tube 26 is connected to support seat 27, which is provided with an external thread on the yarn tube 26, which is connected by the veil tube 26 and the first shell 71 through the thread;

[0114] The first shell 71 and the velvet device 2 form a media cavity. There is the first opening 76 and a plug corresponding to the first opening 76 (not shown in the picture);

[0115] The side wall of the first shell 71 is provided with the first cycle outlet 73 and the second cycle port 74. The first cycle port 73 is close to the top of the first shell 71, which Near the bottom of the first shell 71, the first cycle port 73 is higher than 74 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com