A red light blue azo disperse dye with high color intensity and preparation method thereof

A technology of disperse dyes and strength, applied in the direction of azo dyes, monoazo dyes, luminescent materials, etc., can solve the problems of dyeing temperature difference and brightness difference, and achieve the effect of close color, simple method and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Synthesis of 2-amino-3-acetyl-5-nitrothiophene diazonium solution

[0049] In parts by weight, 2-amino-3-acetylthiophene (M141, 4.23 parts) was slowly added to 34 parts of concentrated sulfuric acid whose temperature had dropped to -15°C, and stirred for 30 minutes to fully dissolve. At the same time, under good stirring conditions, within 2 hours at a temperature of -15°C--10°C, evenly and slowly add mixed acid (mixed acid is 5 parts by weight of concentrated sulfuric acid and 1.85 parts of 98% nitric acid), and then add Incubate at an acid temperature for 1 hour, and sample and chromatographically analyze that the raw material content is less than 1%. Then add 1 part of activated carbon, stir for 20 minutes, filter, and the quantitative analysis yield is 95%. The mother liquor is stored at low temperature until use.

[0050] Slowly add 15 parts of propionic acid to the 2-amino-3-acetyl-5-nitrothiophene sulfuric acid solution synthesized above at -5°C-0°C, ...

Embodiment 2

[0051] Embodiment 2: the synthesis of dye A

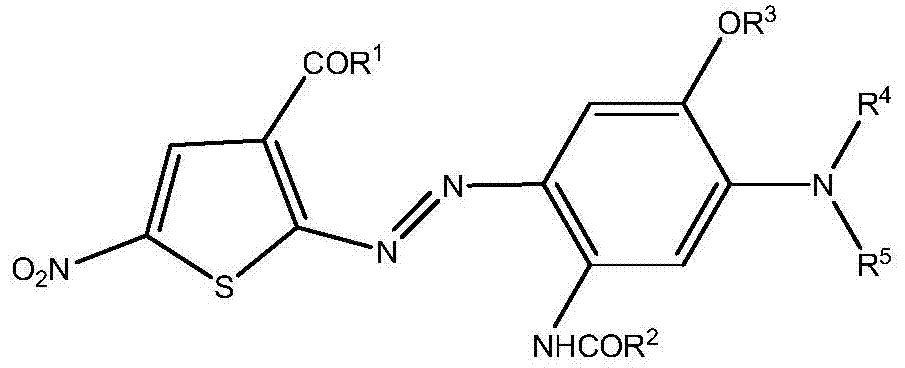

[0052] Coupling components 3-methyl-N-ethyl-N-(ethoxycarbonylpropyl)aniline (M249, 7.45 parts), acetone (30 parts), ice-water mixture (200 parts) and sulfamic acid (0.5 parts) were mixed to obtain a coupling solution. Under a good stirring state, slowly add the obtained diazo component solution into the coupling solution, maintain the temperature at 0°C for 1 hour, filter, wash with water, and dry to obtain dye A (M431, 9.25 parts, yield 75%) The structural formula is as follows:

[0053]

Embodiment 3

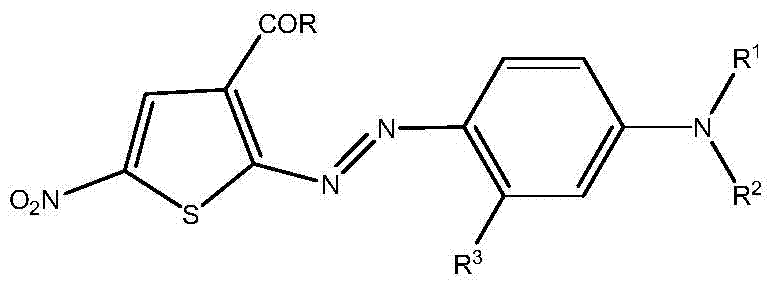

[0054] Example 3: Synthesis of Dye B

[0055] The difference from Example 2 is: 3-methyl-N-ethyl-N-(ethoxycarbonylpropyl) aniline in the above-mentioned coupling solution is replaced by 3-methyl-N-ethyl-N-( Propoxycarbonyl propyl) aniline (M263, 7.57 parts), other charging capacity and operation are constant, obtain dyestuff B (M443, 11.3 parts, yield 90%) structural formula is as follows:

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com