Efficient thermoelectric conversion characteristic ZnSb based thin film and preparing method thereof

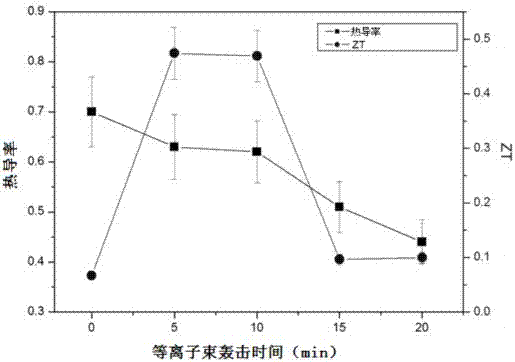

A thermoelectric conversion and thin film technology, applied in vacuum evaporation coating, coating, sputtering coating and other directions, can solve the problem of low thermoelectric characteristics of ZnSb-based thin films, and achieve the effect of improving thermoelectric characteristics and optimizing film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

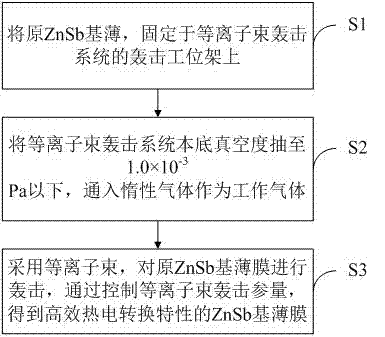

Method used

Image

Examples

Embodiment 1

[0038] The ZnSb-based thin film was prepared by magnetron co-sputtering technology. First, the Sb and Zn targets with a purity of 99.99% were respectively fixed on the two station target racks of the sputtering system; BK7 optical glass was used as the substrate, and the BK7 The optical glass is placed in a container and ultrasonically cleaned with acetone, alcohol and deionized water in sequence; the background vacuum of the sputtering system is pumped to 6.0×10 -4 Pa, the inlet flow rate is 6sccm high-purity Ar gas, and the working pressure is controlled at 6.0×10 -2 Pa; increase the power of the magnetron sputtering system to deposit Sb and Zn on the BK7 optical glass, and the co-sputtering deposition time is 30min.

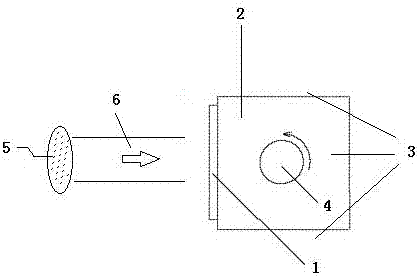

[0039] After the deposition is completed, the ZnSb-based thin film sample is fixed on the bombardment station frame of the plasma beam bombardment system; the vacuum degree of the plasma beam bombardment system is pumped to 6.0×10 -4 Pa, the flow rate is 10 s...

Embodiment 2

[0042] The difference from Example 1 is that the plasma beam is replaced by nitrogen gas.

Embodiment 3

[0044] The difference from Example 1 is that the plasma beam energy is changed to 0.1 KeV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com