Austenitic stainless steel cladding tube for lead-bismuth fast reactor and preparation method thereof

A technology of austenitic stainless steel and cladding tubes, applied in the field of nuclear materials, can solve the problems of large cladding tubes and increased difficulty in manufacturing austenitic stainless steel cladding tubes, so as to avoid corrosion, reduce thermal processing defects, The effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

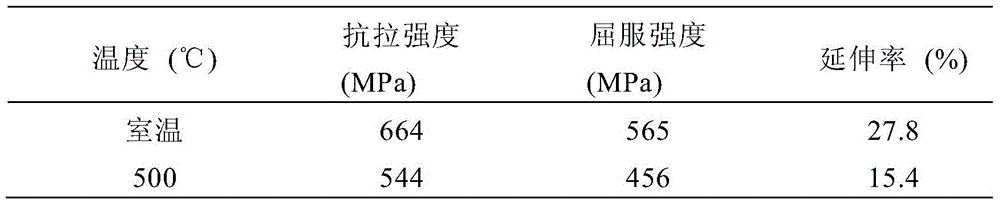

Embodiment 1

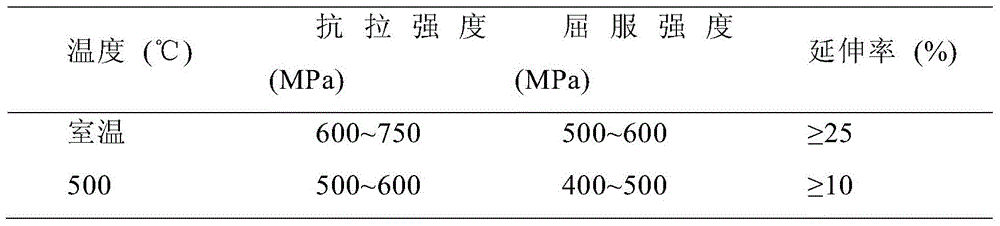

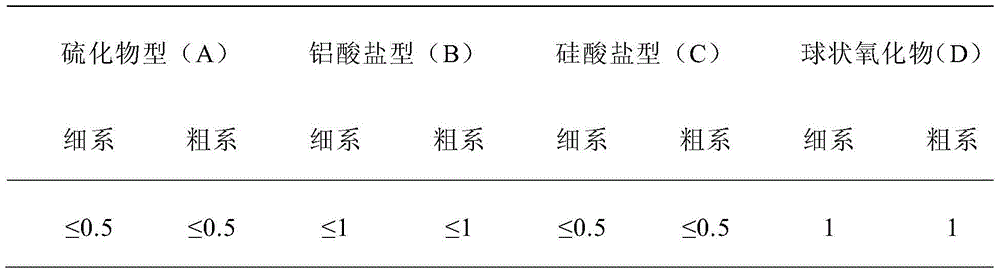

[0063] The specification of the lead-bismuth fast stack austenitic stainless steel cladding tube in this embodiment is Φ15×0.7 mm. The weight percentage of the chemical composition of the austenitic stainless steel cladding tube is:

[0064] C: 0.093%; Si: 0.64%; Ni: 15.46%; Cr: 14.90%; Ti: 0.38%; Mn: 1.68%; Mo: 1.28%; P: 0.02%; N: 0.01%; Avoid impurities.

[0065] The main preparation process is as follows:

[0066] (1) Vacuum induction smelting + vacuum consumable arc smelting is used to carry out double vacuum smelting, and the composition weight percentage of molten steel reaches the above ratio to tap out and cast ingots;

[0067] (2) Use a forging machine to forge an alloy ingot to obtain a billet, and finally obtain a round billet of Φ220 mm; after heating and insulating the billet, use a hot extrusion machine to extrude the billet with an extrusion ratio of 17.5 to obtain the specification It is a tube blank of Φ73×11mm; the tube blank is then subjected to solution ...

Embodiment 2

[0079] The specification of the lead-bismuth fast stack austenitic stainless steel cladding tube in this embodiment is Φ12×0.4 mm. The weight percentage of the chemical composition of the austenitic stainless steel cladding tube is:

[0080] C: 0.09%; Si: 0.56%; Ni: 15.05%; Cr: 15.10%; Ti: 0.41%; Mn: 1.90%; Mo: 1.34%; P: 0.02%; N: 0.01%; Avoid impurities.

[0081] The main preparation process is as follows:

[0082] (1) Vacuum induction smelting + vacuum consumable arc smelting is used to carry out double vacuum smelting, and the composition weight percentage of molten steel reaches the above ratio to tap out and cast ingots;

[0083] (2) Use a forging machine to forge an alloy ingot to obtain a billet, and finally obtain a round billet of Φ180 mm; after heating and insulating the billet, use a hot extrusion machine to extrude the billet with an extrusion ratio of 17.8 to obtain the specification It is a tube blank of Φ58×10mm; the tube blank is then subjected to solution t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com