Austenitic stainless steel for low temperature, casting of austenitic stainless steel and manufacturing method of casting

An austenitic stainless steel, low temperature technology, applied in the field of austenitic stainless steel, can solve the problems of low thermal conductivity, no low temperature brittleness, etc., and achieve the effect of good welding performance, good low temperature impact toughness, and excellent low temperature impact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

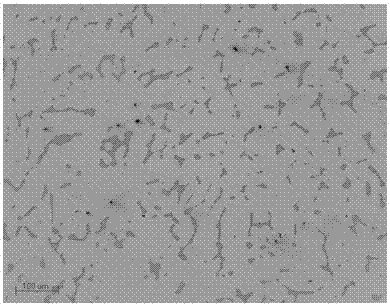

[0041] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0042]The embodiment of the present invention adopts, but is not limited to, austenitic stainless steel F316, which is generally used at low temperature. By increasing the nickel content and ensuring a certain content of nitrogen, the transformation point of martensite is reduced, and the austenite in the alloy is more stable. The specific plan is: an austenitic stainless steel for low temperature, which contains carbon (C): 0.08% or less, manganese (Mn): 1.0-1.6%, silicon (Si): 0.6-1.2%, chromium ( Cr): 17.0-20.0%, nickel (Ni): 10.0-13.0%, molybdenum (Mo): 2.0-3.0%, nitrogen (N): 0.04-0.12%, the rest is iron (Fe) and unavoidable impurities; Phosphorus (P) ≤ 0.04% in impurities, sulfur (S) ≤ 0.02%, tin (Sn) ≤ 0.015%, arsenic (As) ≤ 0.01%, lead (Pb) ≤ 0.01%, ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com