Ultrathick large low-temperature ductile cast iron and preparation method thereof

A nodular cast iron, low-temperature technology, which is applied in the field of ultra-thick and large low-temperature nodular cast iron and its preparation, can solve the problems of less research on low-temperature nodular cast iron, achieve the effects of shortening the trial production cycle, good core structure, and improving the efficiency of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

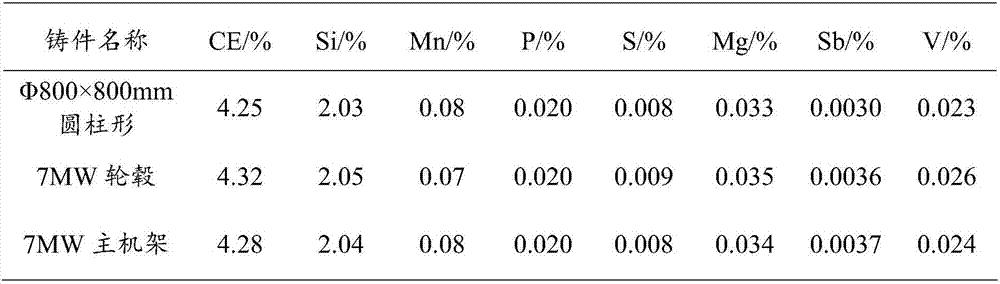

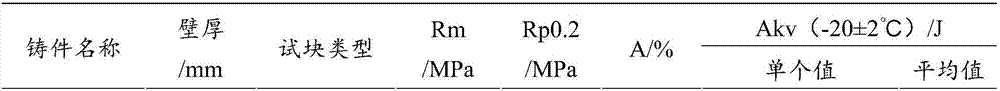

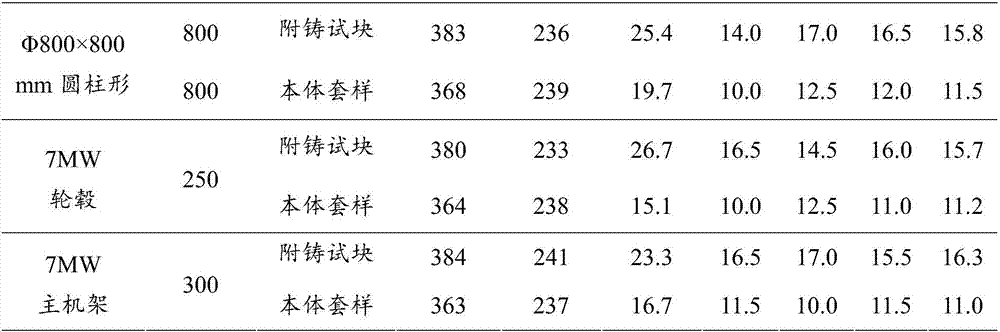

Embodiment 1~3

[0051] (1) Preparation materials

[0052] The smelting materials include 60wt% of pig iron, 25wt% of returned material and 15wt% of steel scrap. The pig iron is high-purity pig iron, wherein C: ≥ 4.0wt%, Mn: ≤ 0.10wt%, P: ≤ 0.025wt%, S: ≤ 0.015wt%, and the sum of anti-spheroidizing harmful alloy elements ≤ 0.08wt%. Thin flake carbon steel scrap is selected as steel scrap, wherein C: ≤0.15wt%, Mn: ≤0.40wt%, P: ≤0.03wt%, S: ≤0.03wt%.

[0053] Nodulizers include new rare earth ferrosilicon magnesium alloy nodulizers and yttrium nodulizers. The composition of the rare earth magnesium alloy nodulizers is: Mg: 4-6wt%, Re: 0.2-0.3wt%, Si: 40 ~45wt%, the rest is iron; the composition formula of yttrium nodulizer is: Mg: 4~6wt%, Re: 0.4~0.6wt%, Si: 40~45wt%, Y: 0.5%~0.7%, the rest is iron .

[0054] The composition of the pretreatment agent is as follows: Si: 60-67wt%, Ba: 7-14wt%, Ca: 0.4-2.0wt%, Al: 0.5-1.7wt%, and the rest is iron.

[0055] The inoculant in the special package i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com