Coke oven combustion emission denitration apparatus and method

A technology for combustion waste gas and denitrification, which is applied in coking ovens, separation methods, chemical instruments and methods, etc., can solve problems such as infeasibility, damage to heat storage bricks, shortened coke oven life, etc., and achieve good denitrification effect, long spraying distance, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

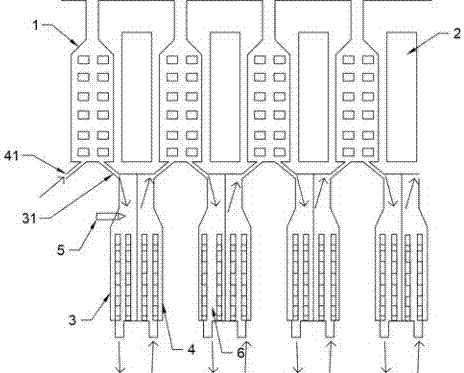

[0035] Such as figure 1 As shown, a coke oven combustion exhaust gas denitrification device includes a plurality of combustion chambers 1 and carbonization chambers 2 connected in phases, and two adjacently connected left and right regenerators are arranged in sequence below the plurality of carbonization chambers 2, which are respectively left and right storage chambers. The heat storage chamber 31 and the right heat storage chamber 32, the heat storage chamber 3 is provided with a number of heat storage bricks from bottom to top, and a heat exchange channel 6 is formed between the heat storage bricks, the heat storage chamber 3 and the combustion chamber 1 is provided with a gas channel 4, above the regenerator brick, on the side of the regenerator 3, and at a position where the temperature is 1100°C<t≤1300°C, there is a nozzle for spraying neutral or near-neutral, liquid denitrification agent Injector 5.

[0036]Among them, the injector 5 chooses the injector whose injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com