Device for simultaneously desulfurizing and denitrating smoke gas through multi-stage turbocharging turbulence wet process and application method

A technology of turbocharging, desulfurization and denitrification, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of only desulfurization, high temperature, and only denitrification, and achieves the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

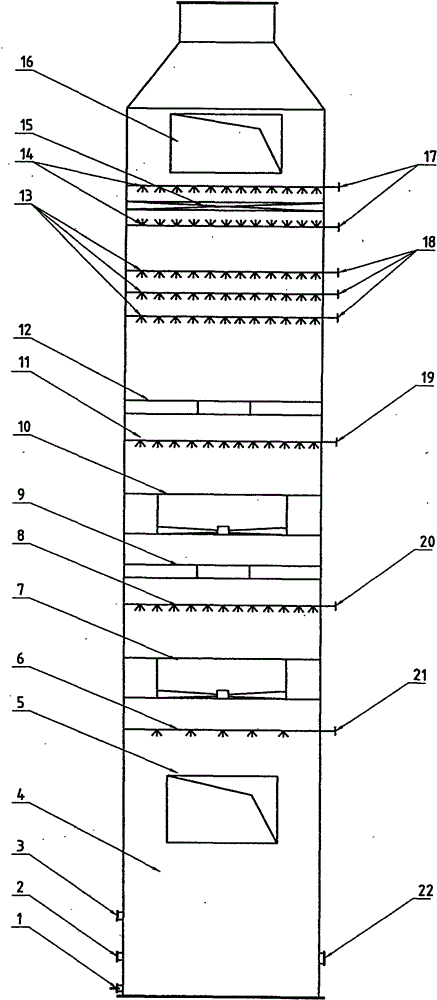

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 2 Shown:

[0058] A flue gas multi-stage turbocharged turbulent wet simultaneous desulfurization and denitrification device, consisting of a sewage pipe 1, a desulfurizer inlet pipe 2, a water pipe 3, a body 4, a flue gas inlet 5, a desulfurization A nozzle 6, and a first-stage turbocharged turbulent flow 7, desulfurization B nozzle 8, lower receiving tank 9, two-stage turbocharger turbulence device 10, denitration C nozzle 11, upper receiving tank 12, denitration D nozzle 13, water nozzle 14, mist eliminator 15, flue gas outlet 16, inlet Water pipe 17, denitrification D pipe 18, denitration C pipe 19, desulfurization B pipe 20, desulfurization A pipe 21, desulfurization agent outlet pipe 22, primary turbocharger turbulence device;

[0059] The flue gas multi-stage turbocharged turbulent wet simultaneous desulfurization and denitrifi...

specific Embodiment approach 2

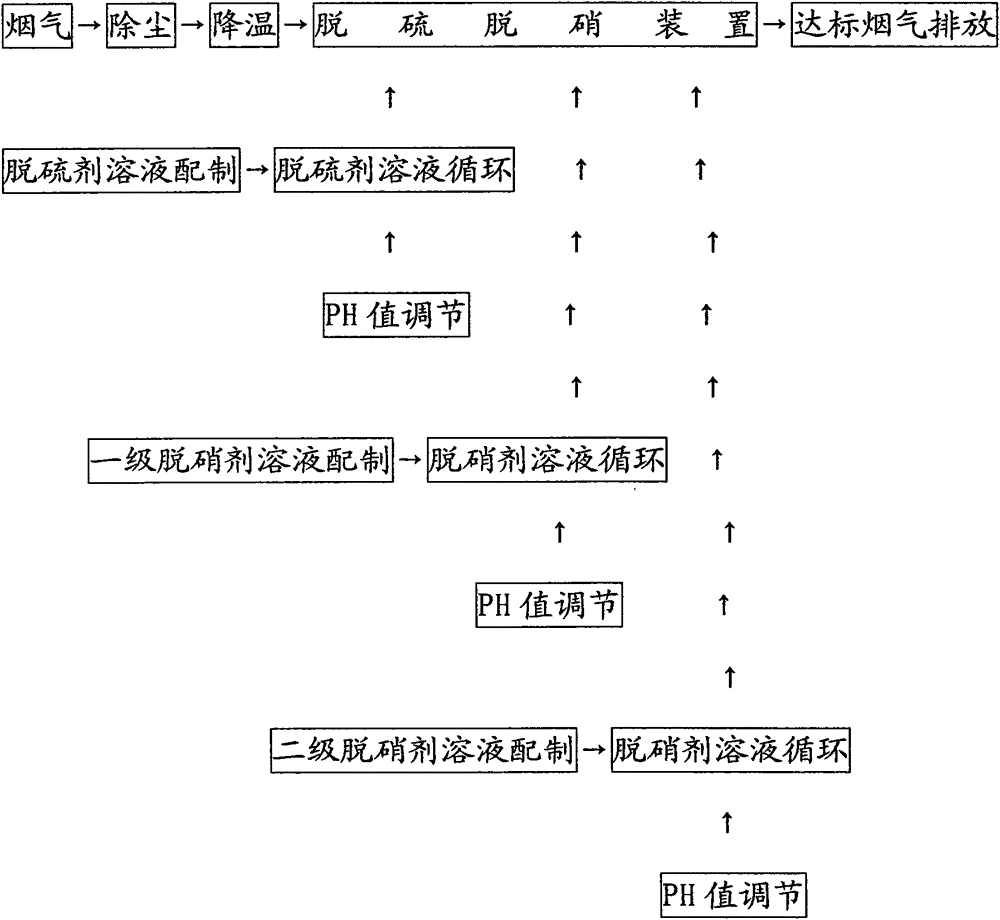

[0064] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , figure 2 Shown:

[0065] A method for using a flue gas multi-stage turbocharged turbulent wet simultaneous desulfurization and denitrification device, using the flue gas multistage turbocharged turbulent wet simultaneous desulfurization and denitrification device, the operation steps:

[0066] (1) Preparation: firstly close the sewage pipe, desulfurizer inlet pipe and water pipe, open the desulfurization pipe A, desulfurization pipe B, denitration pipe C, and denitration pipe D so that their respective nozzles can be sprayed, thus making preparations for use;

[0067] (2) Flue gas desulfurization and denitrification: During the process of flue gas entering the body from the flue gas inlet and then rising until it is discharged from the flue gas outlet:

[0068] ①, flue gas desulfurization: the desulfurization agent used in flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com