Ultra-low NOx emission submerged combustion type gasification system capable of deeply utilizing waste heat

A technology of submerged combustion and gasification system, applied in general control systems, burners, combustion methods, etc., can solve problems such as polluting the environment and a large amount of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

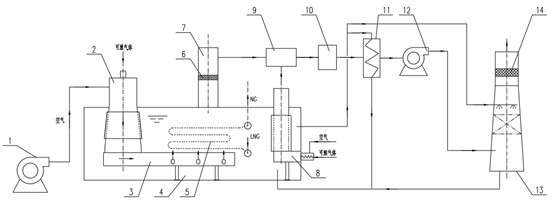

[0024] Such as figure 1 shown.

[0025] 9. An ultra-low NOx emission submerged combustion gasification system for deep utilization of waste heat. It is characterized in that it includes main fan 1, main burner 2, flue gas distributor 3, water tank 4, gasification tube bundle 5, 1# demister 6, chimney 7, auxiliary burner 8, gas mixer 9, denitrification reaction Device 10, heat exchanger 11, induced draft fan 12, scrubber 13, 2# demister 14. The gasification tube bundle 5 can use threaded tubes, internal wave and external threaded tubes, and the material is stainless steel or titanium alloy steel, etc.; the heat exchanger 11 can use special-type tube bundles such as finned tubes. The main fan 1 is connected with the main burner 2 and the auxiliary burner 8, the auxiliary burner 8 is installed in the water tank 4, the main burner 2 is connected with the flue gas distributor 3; the main burner 2, the gasification tube bundle 5, the auxiliary burner 8 is placed in the water tank...

Embodiment 2

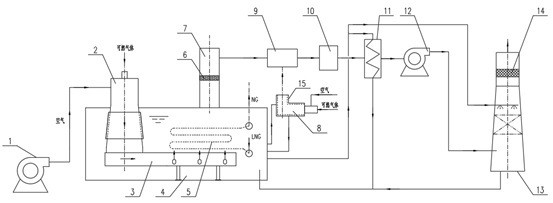

[0031] Such as figure 2 shown.

[0032] The difference between this embodiment and Embodiment 1 is that the auxiliary burner 8 is installed outside the water tank 4. At this time, a water jacket 15 should be provided outside the auxiliary burner 8, and the water from the water tank 4 is circulated in the water jacket 15. , to keep the auxiliary burner 8 cool, so as to avoid setting the refractory material inside the burner 8 . The rest are all the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap