SCR denitration catalyst for tail gas treatment of marine diesel engine

A technology for denitrification catalysts and marine diesel engines, which is applied in the direction of physical/chemical process catalysts, mechanical equipment, combustion engines, etc., can solve the problems of the decrease of specific surface area and the influence of catalyst denitrification activity, improve the mechanical strength, solve the problem of tail gas denitration Effect of lowering molding and calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

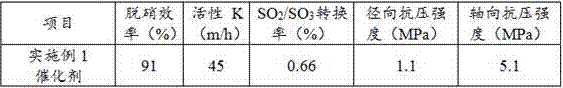

Embodiment 1

[0026] The embodiment of the SCR denitrification catalyst for denitrification of marine diesel engine tail gas is:

[0027] Step 1: Prepare polyacrylamide into an acidic aqueous solution with a mass concentration of 0.5% and PH=3, and mix the diatomite with a particle size of 1000 mesh and the acidic aqueous solution of polyacrylamide under the action of ultrasound in a mass ratio of 1.2:1. , standing in a closed environment for 4 hours to obtain refined diatomite;

[0028] Step 2: Mix butyl titanate sol (with TiO 2 ) and the refined diatomite obtained in step 1 were quickly mixed evenly under ultrasonic conditions, and dried at 105°C after standing for 6 hours;

[0029] Step 3: Calcining the mixture obtained in Step 2 at 650° C. for 4 hours to obtain an SCR catalyst carrier;

[0030] Step 4: Anatase TiO 2 The common carrier composed of refined diatomite accounts for 85% of the mass fraction, and the product is obtained after mixing with active components, additives and mol...

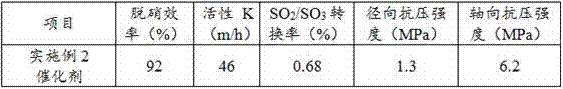

Embodiment 2

[0035] The embodiment of the SCR denitrification catalyst for denitrification of marine diesel engine tail gas is:

[0036] Step 1: Prepare polyacrylamide into an acidic aqueous solution with a mass concentration of 0.3% and PH=4, and mix the diatomite with a particle size of 1500 mesh and the acidic aqueous solution of polyacrylamide under the action of ultrasound at a mass ratio of 1.5:1. , standing in a closed environment for 4 hours to obtain refined diatomite;

[0037] Step 2: Mix butyl titanate sol (with TiO 2 ) and the refined diatomite obtained in step 1 were quickly mixed evenly under ultrasonic conditions, and dried at 105°C after standing for 6 hours;

[0038] Step 3: Calcining the mixture obtained in Step 2 at 650° C. for 4 hours to obtain an SCR catalyst carrier;

[0039] Step 4: Anatase TiO 2 The common carrier composed of refined diatomite accounts for 80% of the mass fraction, and the product is obtained after mixing with active components, additives and mol...

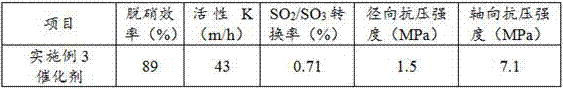

Embodiment 3

[0044] The embodiment of the SCR denitrification catalyst for denitrification of marine diesel engine tail gas is:

[0045] Step 1: Prepare the cellulose into an acidic aqueous solution with a mass concentration of 0.5% and PH=3, and fully stir and mix the diatomite with a particle size of 2000 mesh and polyacrylamide acidic aqueous solution under the action of ultrasound at a mass ratio of 1.5:1. Stand still for 4 hours in a closed environment to obtain refined diatomite;

[0046] Step 2: Mix butyl titanate sol (with TiO 2 ) and the refined diatomite obtained in step 1 were quickly mixed evenly under ultrasonic conditions, and dried at 105°C after standing for 6 hours;

[0047] Step 3: Calcining the mixture obtained in Step 2 at 620° C. for 4 hours to obtain an SCR catalyst carrier;

[0048] Step 4: Anatase TiO 2 The common carrier composed of refined diatomite accounts for 85% of the mass fraction, and the product is obtained after mixing with active components, additives a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com