A kind of epoxy resin-graphene interface chemical bonding anticorrosion coating and preparation method

A technology of epoxy resin and interface chemistry, applied in epoxy resin coatings, anti-corrosion coatings, conductive coatings, etc., can solve problems such as large differences in molecular structure, poor interface compatibility, etc. The effect of improving adhesion and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

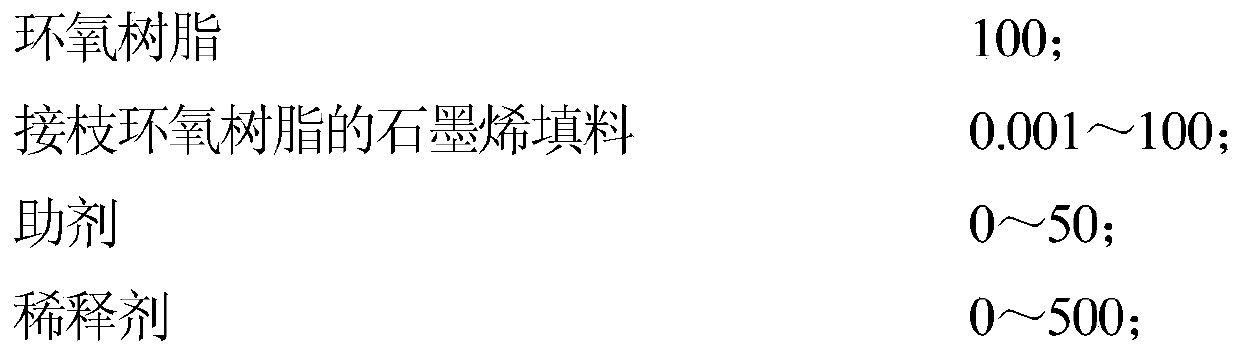

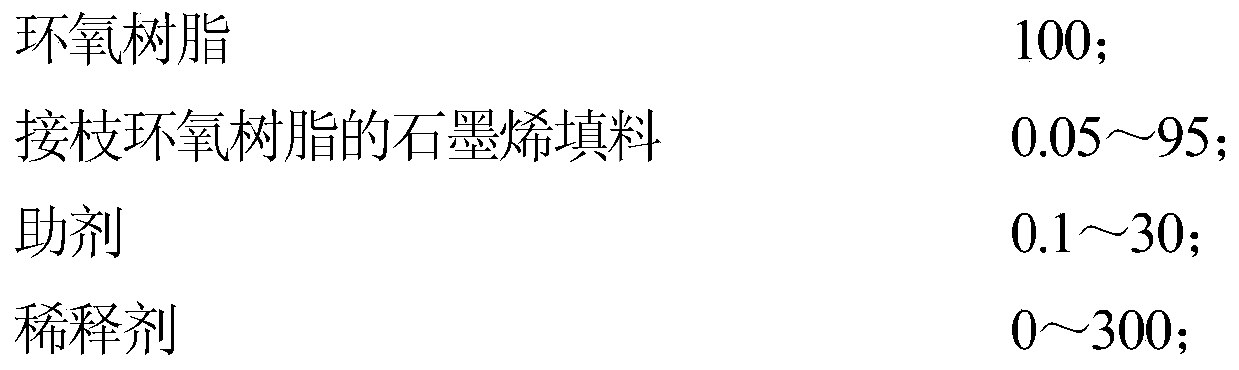

Method used

Image

Examples

Embodiment 1

[0038] First disperse 100 grams of multi-layer graphene in 2000 grams of deionized water to prepare a graphene dispersion under stirring conditions, and at the same time disperse 200 grams of hydrogen peroxide and 200 grams of sodium hydroxide in 1000 grams of deionized water to prepare peroxide Dispersion liquid, then under the condition of stirring, peroxide dispersion liquid is added drop-wise in the graphene dispersion liquid after stirring evenly, with ultrasonic treatment 120 minutes, the product centrifugation of ultrasonic treatment removes deionized water, then adds 180 grams of epoxy equivalent 160~180(g.mol -1 ) of bisphenol F type epoxy resin at 140° C. for 0.5 hours to stop the reaction, and the reaction product was repeatedly washed with acetone, and centrifuged or filtered to remove free compounds to obtain graphene fillers grafted with epoxy resin.

[0039] The preparation method of component A of the paint is as follows: 95 grams of graphene filler grafted wit...

Embodiment 2

[0041] First disperse 100 grams of double-layer graphene in 1000 grams of deionized water under stirring to prepare a graphene dispersion, and disperse 10 grams of sodium peroxide and 5 grams of potassium hydroxide in 100 grams of deionized water to prepare peroxide Dispersion, then under the condition of stirring, the peroxide dispersion is added dropwise to the graphene dispersion and stirred evenly, and treated with ultrasonic wave for 10 minutes, after the product of ultrasonic treatment is centrifuged to remove deionized water, add 1 gram of epoxy equivalent 160 ~180(g.mol -1 ) of bisphenol F epoxy resin at 120° C. for 8 hours to stop the reaction, and the reaction product was repeatedly washed with acetone, and centrifuged or filtered to remove free compounds to obtain graphene fillers grafted with epoxy resin.

[0042] The preparation method of component A of the paint is as follows: 0.05 grams of graphene filler grafted with epoxy resin, 100 grams of epoxy equivalent 1...

Embodiment 3

[0044] First disperse 100 grams of multilayer graphene in 2000 grams of toluene under stirring to prepare a graphene dispersion, and simultaneously disperse 10 grams of dibenzoyl peroxide and 6 grams of sulfuric acid in 100 grams of toluene to prepare a peroxide dispersion , then add the peroxide dispersion liquid dropwise to the graphene dispersion liquid under the condition of stirring, stir evenly, treat with ultrasonic wave for 60 minutes, add 90 grams of epoxy equivalent 200~220 (g.mol -1 ) of aliphatic epoxy resin at 110°C for 24 hours to stop the reaction, and the reaction product was repeatedly washed with acetone, and centrifuged or filtered to remove free compounds to obtain graphene fillers grafted with epoxy resin.

[0045] The preparation method of component A of the paint is: in a clean container, 1 gram of graphene filler grafted with epoxy resin, 100 grams of epoxy equivalent 455-556 (g.mol -1 ) of bisphenol F epoxy resin, 50 grams of toluene, 10 grams of isopr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com