Preparation method of artificial quartz stone composite color plate

A technology of artificial quartz stone and compound color plate, which is applied in the field of artificial quartz stone, can solve the problems of uneven quality of molded products, easy flow of compound color plates, and weak market competitiveness, etc. good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

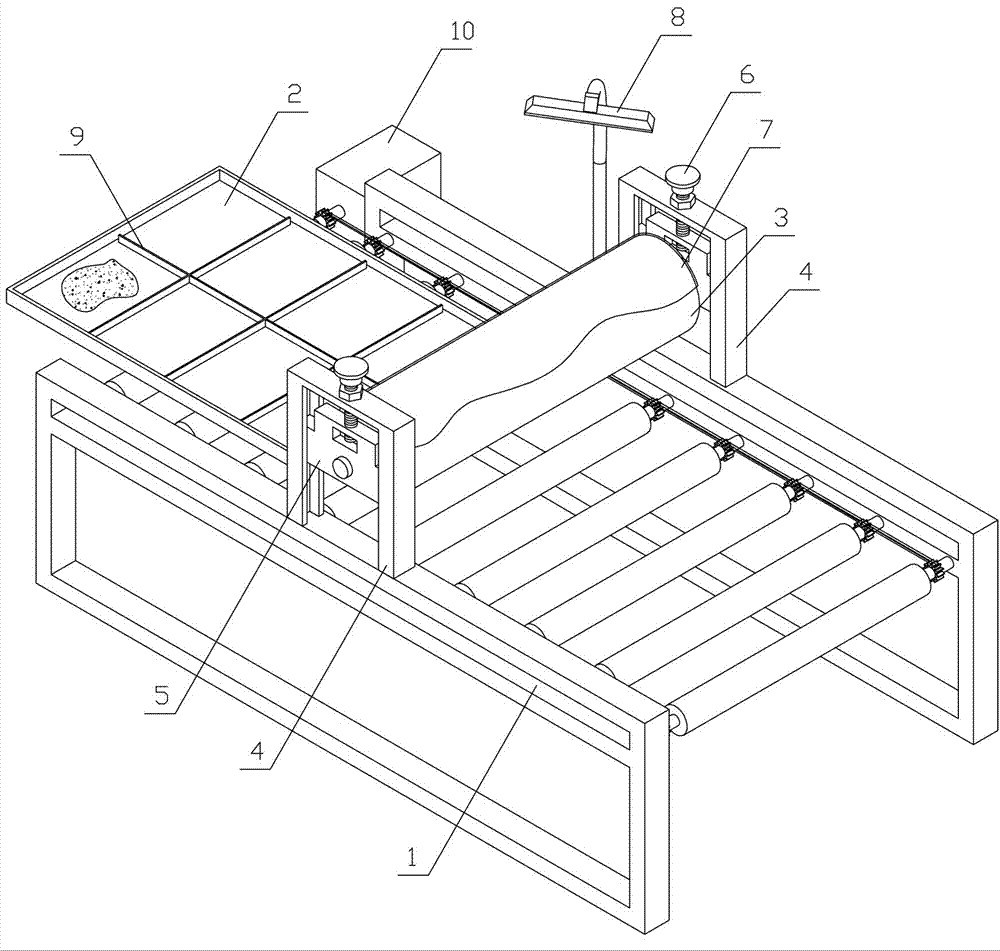

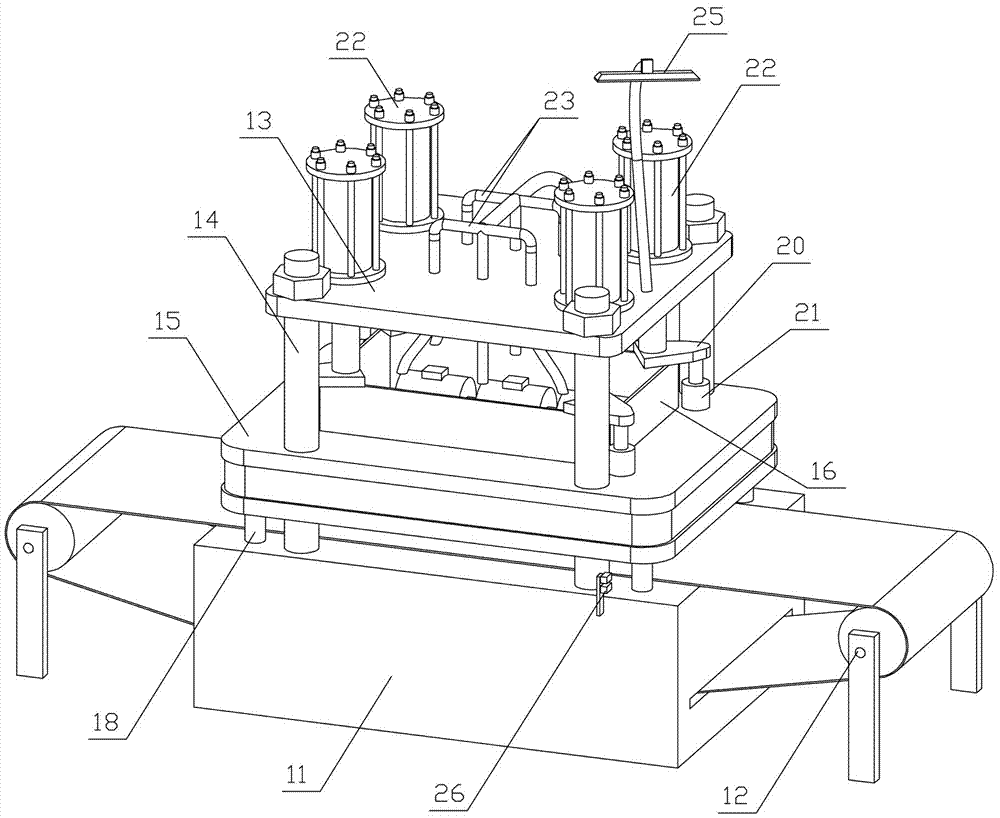

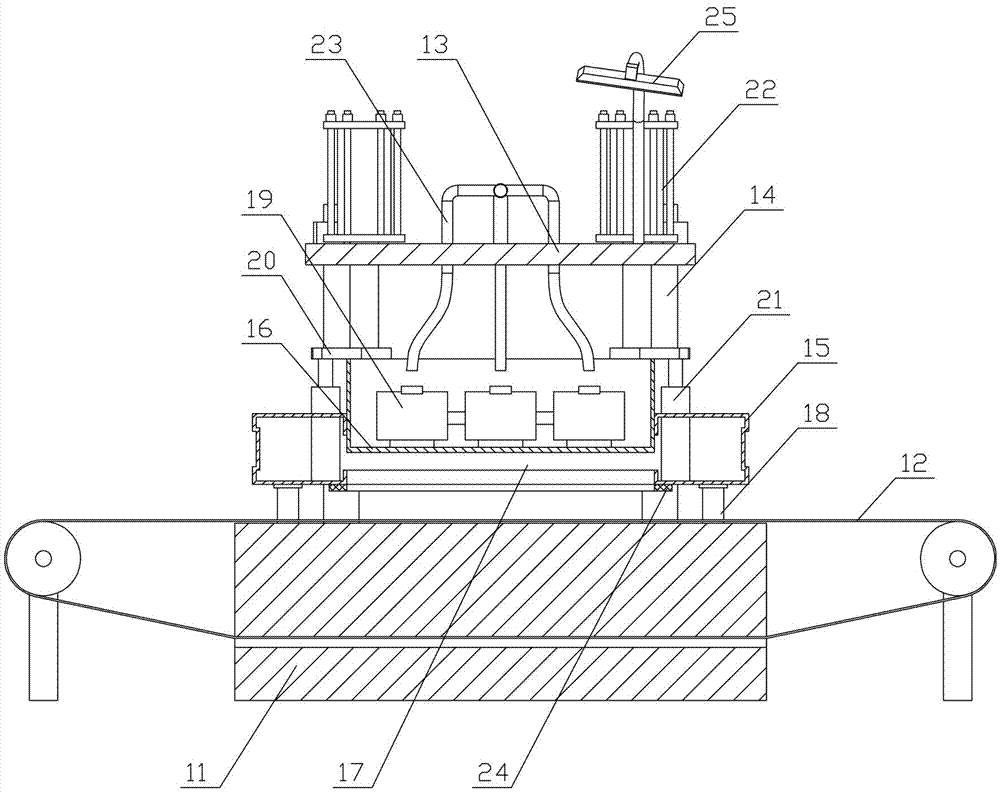

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the artificial quartz stone compound color plate of the present embodiment is made up of following steps successively:

[0040] (1) Preparation of materials First, the raw materials are mixed according to the following parts by weight: 32 parts of 4-16 mesh quartz sand, 38 parts of 40-120 mesh quartz sand, 32 parts of 325-mesh quartz powder, 8 parts of unsaturated polyester resin, silane coupling 0.9 parts of agent, 1.2 parts of methyl ethyl ketone peroxide, 0.05 parts of cobalt isooctanoate, 0.12 parts of pigment, 0.4 parts of modified fumed silica;

[0041] During preparation, firstly, the quartz sand and quartz powder of different meshes are respectively modified with silane coupling agent, and then the modified quartz sand and quartz powder are put into a mixer and stirred evenly to make a quartz sand powder mixture. Then according to the color of the complex color board to be prepared and the proportion by weight, weigh and distribute the ...

Embodiment 2

[0061] The ratio by weight of the raw material of artificial quartz stone compound color plate in this embodiment is as follows: 25 parts of 4-16 mesh quartz sand, 45 parts of 40-120 mesh quartz sand, 30 parts of 325-mesh quartz powder, 7 parts of unsaturated polyester resin , 0.7 parts of a silane coupling agent, 1.5 parts of a curing agent, 0.02 parts of an accelerator, 0.04 parts of a pigment, and 0.2 parts of a modified fumed silica.

[0062] The preparation method is the same as in Example 1.

Embodiment 3

[0064] In this embodiment, the ratio by weight of the raw materials for the artificial quartz stone compound color plate is as follows: 40 parts of 4-16 mesh quartz sand, 30 parts of 40-120 mesh quartz sand, 35 parts of 325-mesh quartz powder, and 9 parts of unsaturated polyester resin , 1 part of silane coupling agent, 0.8 part of curing agent, 0.08 part of accelerator, 0.2 part of pigment, 0.45 part of modified fumed silica.

[0065] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com