Corrugated paper cross cutting machine knife roller

A cross-cutting machine and corrugated paper technology, applied in metal processing, etc., can solve the problems of unsatisfactory mechanical performance improvement, lower quality of paper cutting by knife roller, energy consumption, serious consumables, etc., achieve high specific elastic modulus, improve paper cutting Quality, the effect of reducing the overall moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

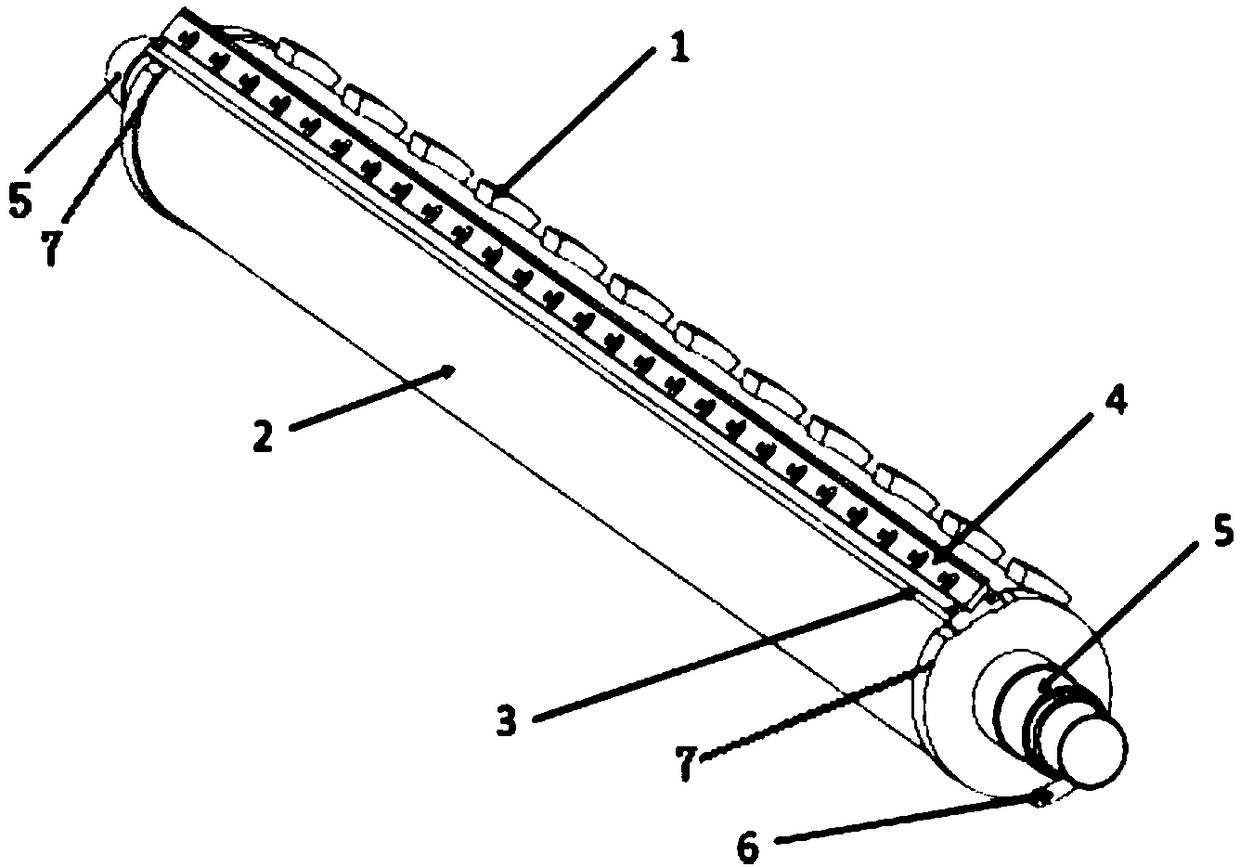

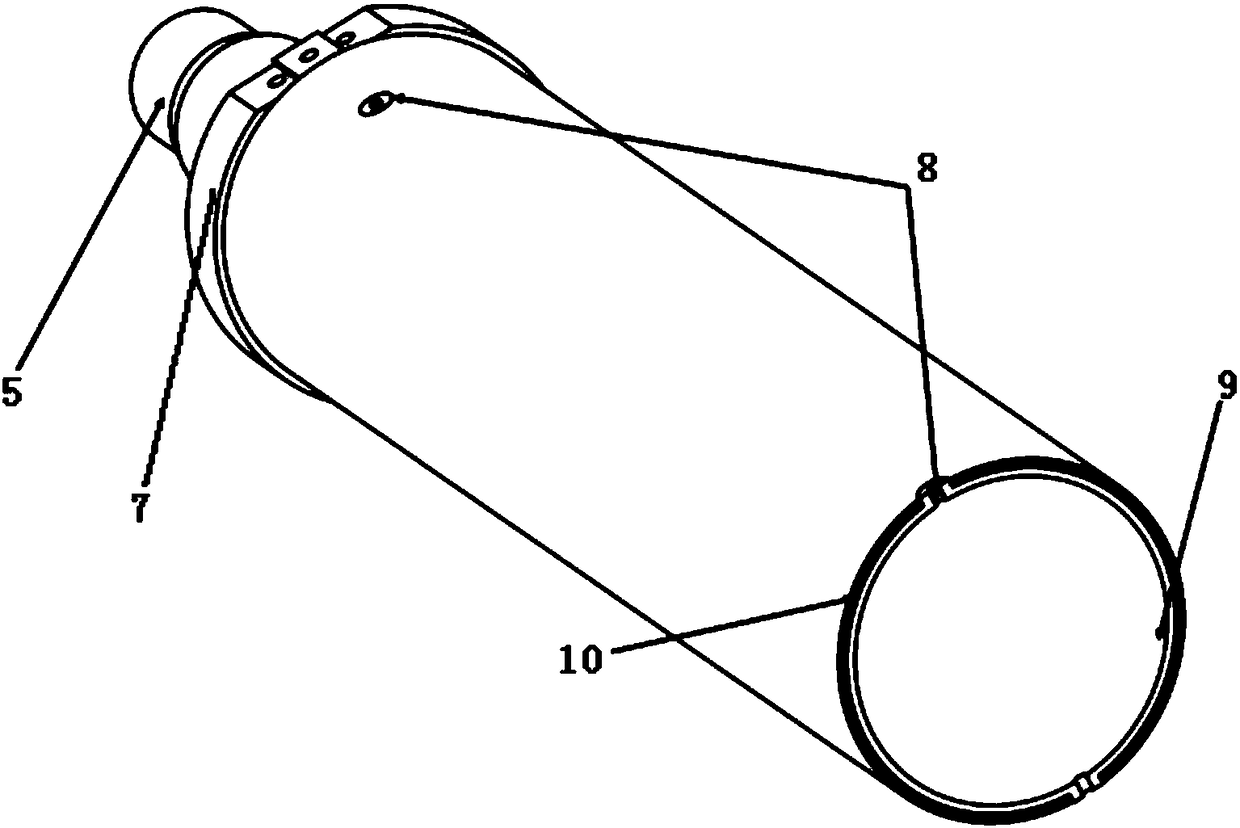

[0034] Such as Figure 1 to Figure 3 As shown, a corrugated cardboard cross-cutting machine knife roll includes a roll body 2 and a shaft head 5 arranged at both ends of the roll body 2 for supporting and transmitting power (the shaft head 5 is equipped with a tapered roller bearing for support and gear for transmission), the roller body 2 includes a steel inner liner 9 and a layer 10 with a certain thickness formed on the outer circle of the inner liner 9 by winding and solidifying carbon fibers. The weight bar 6 and the paper guide ring 1 (the knife rest 3 is installed on the layer 10 with a certain helix angle), the knife rest 3 and the counterweight bar 6 are symmetrical about the axis (the counterweight bar 6 is installed to balance the knife rest 3 and The effect of cutter 4), the paper guide ring 1 is located near the knife holder 3 (the paper g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com