Pericardial collagen composite material and preparation method and application thereof

A composite material and collagen technology, applied in prosthetics, tissue regeneration, medical science, etc., can solve the problems of osteoinductivity and bionic bone structure, and achieve sufficient space maintenance ability, good compactness, and biodegradation time prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

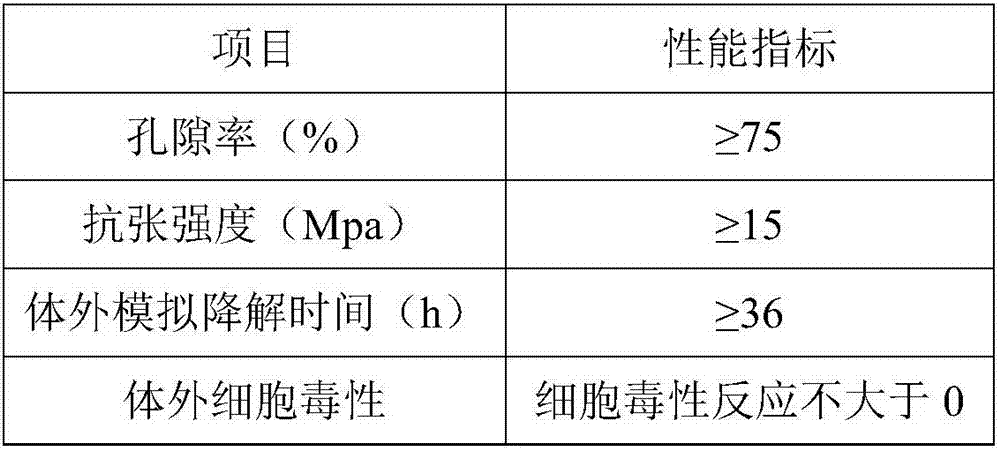

Image

Examples

Embodiment 1

[0027] This embodiment provides a polysaccharide-containing pericardial composite material, which is prepared by the following steps:

[0028] 1. Remove the fat from the pericardium purchased in the market with a glass plate or steel plate, and freeze it in the refrigerator for 24 hours;

[0029] 2. Put the fat-removed pericardium into a beaker and rinse it with deionized water for 3 times, each time for 5 minutes. At this time, if there is any fat tissue, remove it sharply with scissors and tweezers;

[0030] 3. Degreasing: the ratio of solid to liquid is 3:1, the temperature is 40°C, add a degreasing agent with a weight ratio of 0.6% of pig pericardium, and act for 1.5 hours. The ratio of solid to liquid is 4:1, washed twice with water;

[0031] 4. Alkali treatment: the ratio of solid to liquid is 3:1, the temperature is 28°C, add sodium hydroxide with a mass ratio of 0.8% of pig pericardium, and 0.6% degreasing agent, turn for 30 minutes, turn for 10 minutes every 50 minut...

Embodiment 2

[0043] This embodiment provides a pericardial composite material containing bone substitute material or growth factor, which is prepared by the following steps:

[0044] Operate according to example 1

[0045] 7. Compounding: liquid ratio 2.5:1, temperature 35°C, pH value 6.4-6.8, hydroxyapatite 2.0%, react for 90 minutes, wash with PBS;

[0046] 8. Cross-linking: liquid ratio 2.0:1, temperature 30°C, glutaraldehyde 0.2%, add in portions, adjust the pH value to 8, react for 60 minutes, wash with water until the pH value is neutral;

[0047] 9. Washing with PBS: liquid ratio 3:1, temperature 25°C, wash 3 times.

[0048] 10. Disinfection: cobalt 60 irradiation sterilization.

[0049] The pericardial collagen composite material prepared by the above method can be used as a bone repair material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com