An open-frame fluorine-based solid-state electrolyte material and its preparation method

An electrolyte material and solid electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc., can solve the problems of limited electrochemical stability window, instability, complex phase diagram, etc. The effect of improving intrinsic ionic conductivity, inhibiting battery performance degradation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

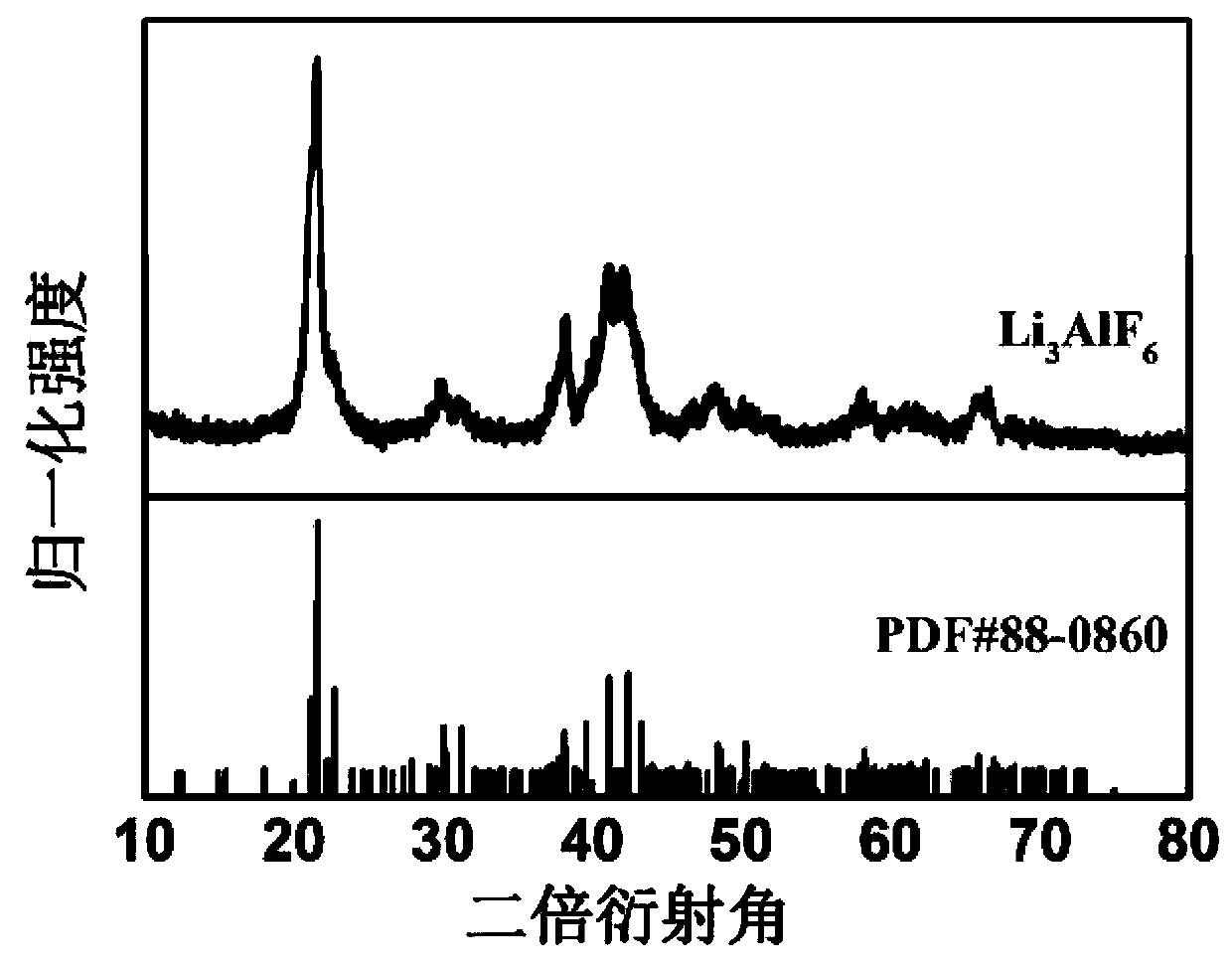

[0054] 1) Li 3 AlF 6 Ionic Liquid-Based Preparation of Solid Electrolyte Nanoparticles:

[0055] Weigh 0.3g of Li 2 CO 3 Added to 10 mL of 1-butyl-3-methylimidazolium tetrafluoroborate (BmimBF 4 ) in the ionic liquid, stirred at room temperature for 6 hours to obtain a uniform cloudy solution. Then, while stirring, slowly add 1 g of Al(NO 3 ) 3 9H 2 O, stirring continued for 12 hours to obtain a cloudy solution from which a precipitate could precipitate. The reaction precipitate was repeatedly centrifuged and washed with anhydrous acetone, and vacuum-dried at 80° C. to obtain the solid electrolyte material. Li 3 AlF 6 SEM of solid electrolyte nanoparticles as attached figure 1 Shown, illustrate that embodiment (1) can successfully prepare the nanoscale solid electrolyte material of 20-50nm scale, and because potential surface modification (being the conformal coating of ionic liquid positive group), can reduce particle surface energy, It is conducive to uniform dis...

Embodiment 2

[0057] 1)Na 3 AlF 6 Ionic Liquid-Based Preparation of Solid Electrolytes:

[0058] Weigh 0.424g of Na 2 CO 3 Added to 10 mL of 1-butyl-3-methylimidazolium tetrafluoroborate (BmimBF 4 ) in the ionic liquid, stirred at room temperature for 6 hours to obtain a uniform cloudy solution. Then, while stirring, slowly add 1 g of Al(NO 3 ) 3 9H 2 O, stirring continued for 12 hours to obtain a cloudy solution from which a precipitate could precipitate. Wash the reaction precipitate by repeated centrifugation with anhydrous acetone, and vacuum-dry it at 80°C to obtain Na 3 AlF 6 A solid electrolyte material for the main phase. XRD attached image 3 As shown, a sharper main phase Na can be found 3 AlF 6 The diffraction peak pattern is doped with a broad heterophase Na 5 Al 3 f 14 diffraction peaks.

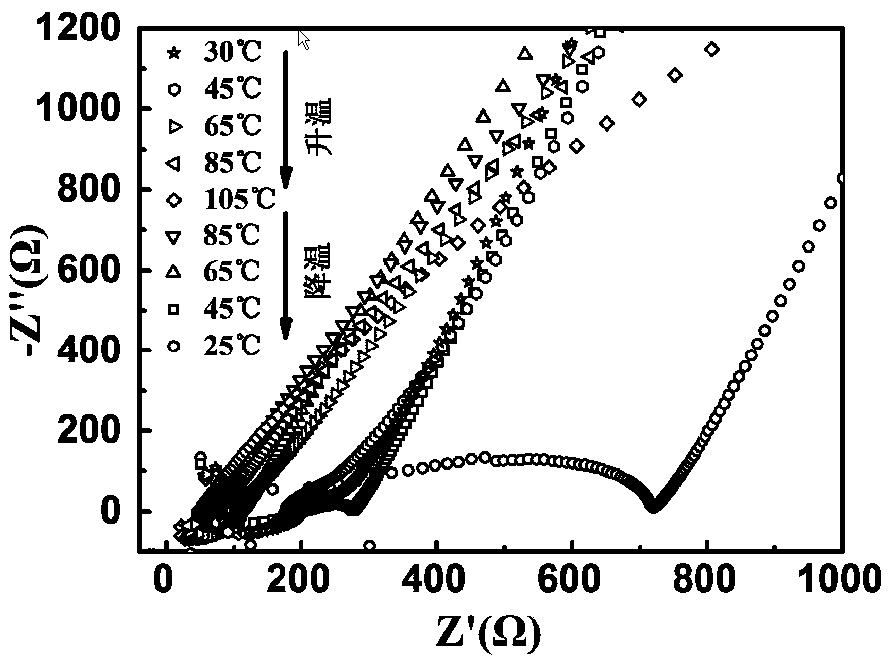

[0059]2) Conductivity test of solid electrolyte sheet:

[0060] Na prepared by embodiment 2 3 AlF 6 The solid electrolyte powder is pressed into a disk with a thickness of...

Embodiment 3

[0062] 1)Na 3 Li 3 al 2 f 12 High-temperature solid-state reaction preparation of solid electrolytes:

[0063] Weigh 0.5g of NaF, 0.31g of LiF and 0.67g of AlF 3 , grind uniformly in the agate grinding body, press the mixture into a disc with a diameter of 10mm under a pressure of 15MPa, and then seal it in a stainless steel reaction kettle filled with an Ar atmosphere, and perform a solid-state reaction at 700°C for 10 hours, and the pressed tablet Crush and grind evenly again to get the desired product. Its XRD is attached Figure 5 As shown, the sharp Na 3 Li 3 al 2 f 12 Diffraction peaks confirm the phase-pure nature of the material.

[0064] 2) Conductivity test of solid electrolyte sheet:

[0065] Na prepared by embodiment 3 3 Li 3 al 2 f 12 The solid electrolyte powder is pressed into a disk with a thickness of 1mm and a diameter of 10mm, and the pressure of the tablet is 15MPa. Au electrodes with a diameter of 8mm were vapor-deposited on both sides of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com