Low-foam dispersant, preparation method and application thereof

A dispersant and initiator technology, which is applied in the synthesis of polymer compounds and low-foaming dispersants. It can solve the problems of uneven spray liquid, easy overflow of liquid medicine, and poor foam suppression ability, so as to achieve less foam and less foam. The effect of strong lipophilicity and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

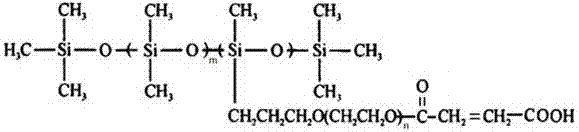

[0035] Preparation of Monomer A:

[0036] In a four-neck flask with 100g of toluene, add 61.8g of polyether-modified silicone oil (m is 4, n is 15, molecular weight is 1236) and 5.90g of maleic anhydride, after all dissolved, stir the reaction at 40°C After 5h, the heating was stopped, toluene and residual maleic anhydride were removed, the temperature was lowered and the material was discharged to obtain a liquid product, monomer A.

[0037] The preparation method of low foam dispersant:

[0038] (1) In the reactor, add 30g of monomer A prepared above, 20.6g of monomer B (sodium styrene sulfonate), 1g of sodium lauryl sulfate, 80g of water, stir and heat to 70°C;

[0039] (2) Add 9.68g monomer C (methyl acrylate) and initiator aqueous solution (a mixture of 0.3g ammonium persulfate and 15g water) dropwise into the reactor at the same time, and the dropping time is 2h;

[0040] (3) After reacting for 3 hours, cool down to normal temperature, adjust the pH to 5.0 with 30% sod...

Embodiment 2

[0042] Preparation of Monomer A:

[0043] In a four-neck flask with 100g of toluene, add 67.04g of polyether-modified silicone oil (m is 10, n is 53, molecular weight is 3352) and 2.36g of maleic anhydride, after they are all dissolved, stir the reaction at 45°C After 7h, the heating was stopped, toluene and residual maleic anhydride were removed, the temperature was lowered and the material was discharged to obtain a liquid product, monomer A.

[0044] The preparation method of low foam dispersant:

[0045] (1) In the reactor, add 30g of monomer A prepared above, 13.76g of monomer B (sodium methacrylate), 0.7g of sodium dodecyl sulfate, and 90g of water, stir and heat to 80°C;

[0046] (2) Add 7.49g of monomer C (styrene) and initiator aqueous solution (a mixture of 1.58g of sodium persulfate and 15g of water) dropwise into the reactor at the same time, and the dropping time is 2.5h;

[0047] (3) After reacting for 5 hours, cool down to normal temperature, adjust the pH to ...

Embodiment 3

[0049] Preparation of Monomer A:

[0050] In a four-neck flask with 100g of toluene, add 72.40g of polyether modified silicone oil (m is 7, n is 23, molecular weight is 1810) and 4.71g of maleic anhydride, after all dissolved, stir the reaction at 35°C After 9h, the heating was stopped, toluene and residual maleic anhydride were removed, the temperature was lowered and the material was discharged to obtain a liquid product, monomer A.

[0051] The preparation method of low foam dispersant:

[0052] (1) In the reactor, add 30g of monomer A prepared above, 13.03g of monomer B (2-acrylamide-2-methylpropanesulfonic acid), 1.2g of sodium lauryl sulfate, 90g of water, and stir Heating to 85°C;

[0053] (2) Add 24.94g monomer C (isooctyl methacrylate) and initiator aqueous solution (a mixture of 1.02g sodium persulfate and 15g water) dropwise into the reactor at the same time, and the dropping time is 3h;

[0054] (3) After reacting for 6 hours, cool down to normal temperature, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com