Rodenticide

A rodenticide and excipient technology, used in biocides, rodenticides, biocides, etc., can solve the problems of increasing conversion costs, low biogas output, and high input costs, reducing environmental pressure and reducing The effect of food use and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Base material 3kg (including protein content 21%, starch content 45%, oil content 5%, moisture 8%), bromadiolone 0.2g, auxiliary materials 1360g (industrial paraffin 600g, maltodextrin 110g, polyvinyl alcohol 80g, isinglass 40g, anhydrous calcium chloride 100g, sorbitol ester 70g, benzoic acid 85g, tartrazine 1g, indigo 5g, sucrose 20g, salt 4g, ethylene glycol 230g, water 15g).

[0070] The above raw materials in parts by weight are fully mixed, dried, and finally granulated to make a blue cylinder with a particle diameter of 1-2 cm.

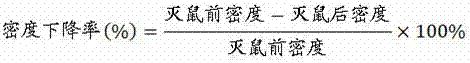

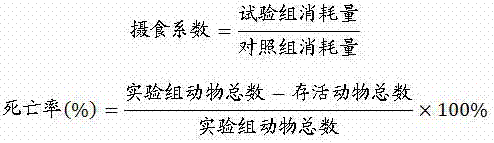

[0071] The palatability test was carried out in the laboratory, and the ingestion coefficient was 0.87 after 4 days, which indicated good palatability; all the test mice died after 5 days. (For the specific method, refer to the above-mentioned rodenticide palatability determination method).

Embodiment 2

[0073] Base material 4kg (including protein content 22%, starch content 47%, oil content 5%, moisture 7%), warfarin 0.2g, auxiliary materials 1655g (industrial paraffin 800g, trehalose 80g, carboxymethyl cellulose 80g, poly Vinyl alcohol 80g, anhydrous calcium chloride 130g, sorbitol ester 80g, sodium dodecylbenzenesulfonate 70g, sodium diacetate 30g, ethyl p-hydroxybenzoate 20g, benzoic acid 35g, potassium sorbate 10g, indigo 3g , sucrose 20g, salt 7g, ethylene glycol 140g, water 70g).

[0074] The above-mentioned raw materials in parts by weight are fully mixed, dried, and finally granulated to make blue granules with a particle diameter of 1-2 cm.

[0075] The palatability test was carried out in the laboratory, and the ingestion coefficient was 0.85 after 4 days, indicating good palatability; all died after 5 days.

Embodiment 3

[0077] Base material 5kg (including protein content 25%, starch content 50%, oil content 5%, moisture 6%), coumateral 0.2g, auxiliary materials 1580g (industrial paraffin 900g, maltodextrin 80g, polyvinyl alcohol 80g, gum arabic 30g, anhydrous copper sulfate 80g, alkylphenol polyoxyethylene ether 75g, ethyl p-hydroxybenzoate 45g, brilliant blue 3g, stevioside 30g, salt 5g, sodium glutamate 2g, ethylene glycol 170g, water 80g) .

[0078] The above raw materials in parts by weight are fully mixed, dried, and finally granulated to make blue walnuts with particle diameters of 1-4 cm.

[0079] The palatability test was carried out in the laboratory. After 4 days, the ingestion coefficient was 1.05, and the palatability was good; all died after 5 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com