High-temperature-resistant binder

A binder and high-temperature-resistant technology, applied in the direction of adhesives, non-polymer adhesive additives, inorganic adhesives, etc., can solve problems such as low construction efficiency, shortened service life of furnaces, and lack of strength, so as to improve construction Efficiency, high refractory temperature, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

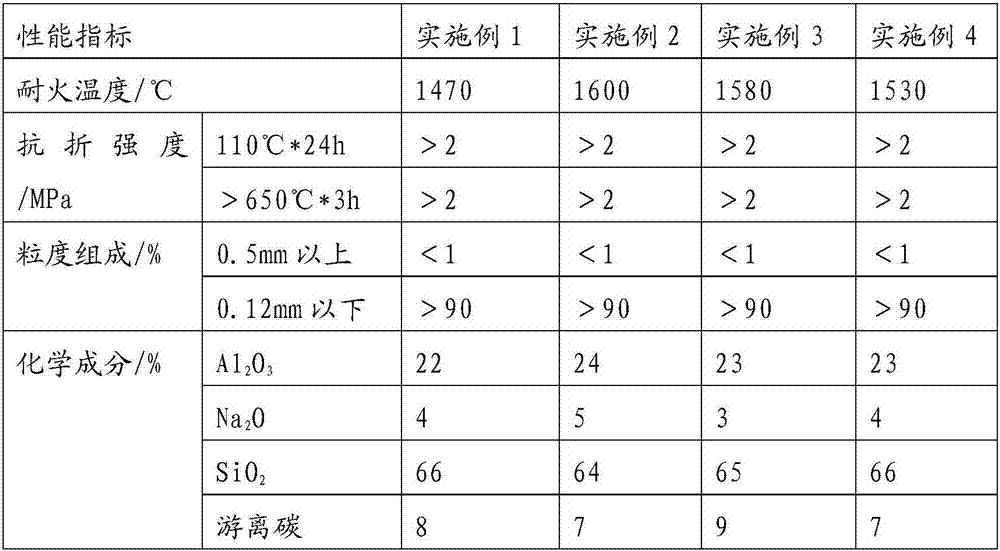

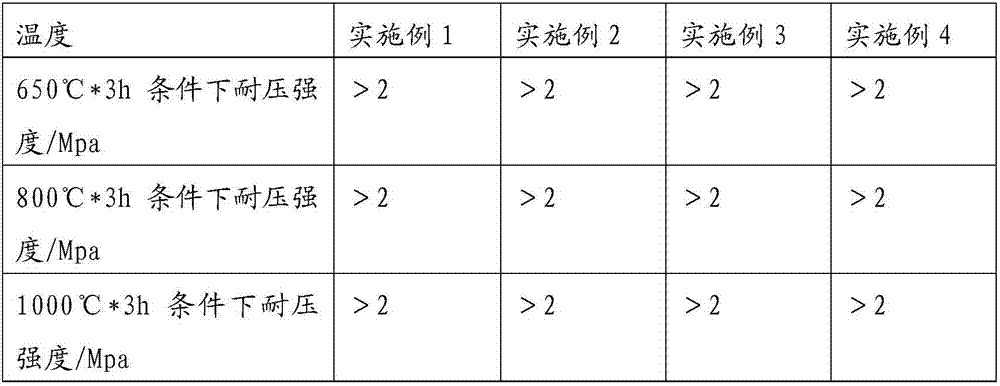

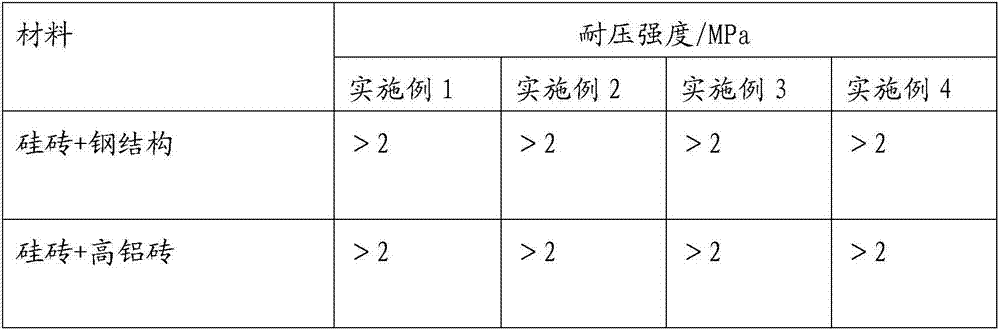

Examples

Embodiment 1

[0042] Raw material composition:

[0043] Percentage by weight: 36% of sodium silicate, 55% of kaolin, 9% of kyanite powder, and the modulus of sodium silicate is 3.55.

[0044] Put sodium silicate and water into a high-speed disperser at a weight ratio of 1:1.3 to disperse for 5 minutes, disperse fully, and become liquid; then add kaolin, disperse at high speed for 10 minutes; finally add kyanite powder, slowly Stir for 1 minute, discharge the ingredients, and seal the package.

Embodiment 2

[0046] Raw material composition:

[0047] Percentage by weight: 40% sodium silicate, 51% kaolin, 9% kyanite powder, and the modulus of sodium silicate is 3.45.

[0048] Put sodium silicate and water into a high-speed disperser at a weight ratio of 1:1.4 to disperse for 5 minutes, disperse fully, and become liquid; then add kaolin, disperse at high speed for 10 minutes; finally add kyanite powder, slowly Stir for 1 minute, discharge the ingredients, and seal the package.

Embodiment 3

[0050] Raw material composition:

[0051] Percentage by weight: 35% of sodium silicate, 57% of kaolin, 8% of kyanite powder, and the modulus of sodium silicate is 3.45.

[0052] Put sodium silicate and water into a high-speed disperser at a weight ratio of 1:1.5 to disperse for 5 minutes, disperse fully, and become liquid; then add kaolin, disperse at high speed for 10 minutes; finally add kyanite powder, slowly Stir for 1 minute, discharge the ingredients, and seal the package.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com