Method for eliminating ammonia inhibition in anaerobic fermentation process of livestock and poultry excrement

A technology of anaerobic fermentation and livestock and poultry manure is applied in the field of agricultural waste resource utilization, which can solve problems such as technical difficulties, and achieve the effects of rapid reaction and reduction of alkali consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

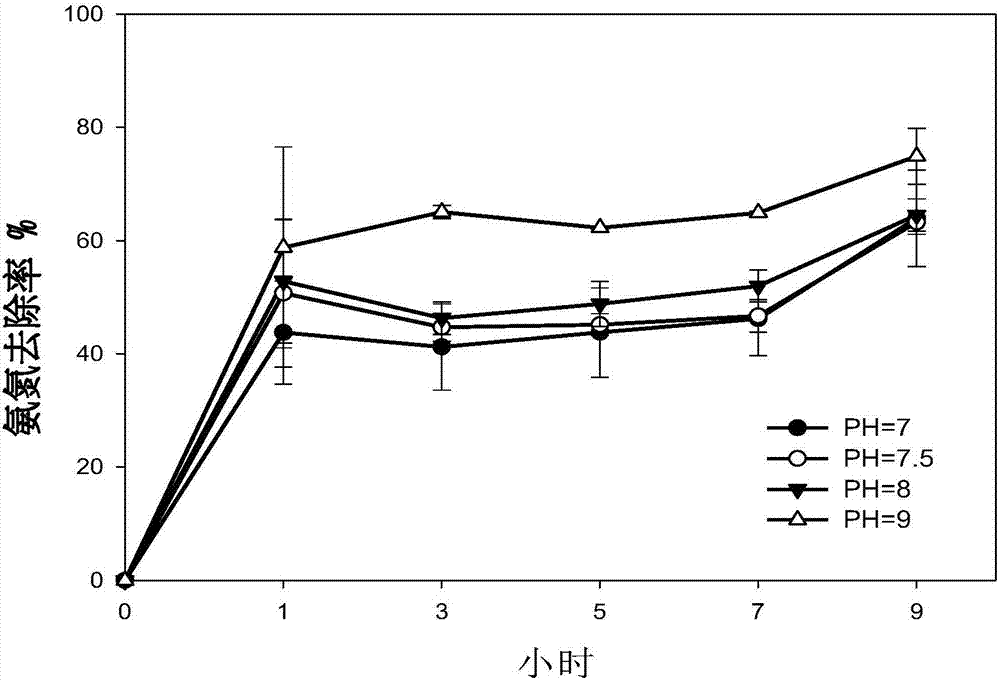

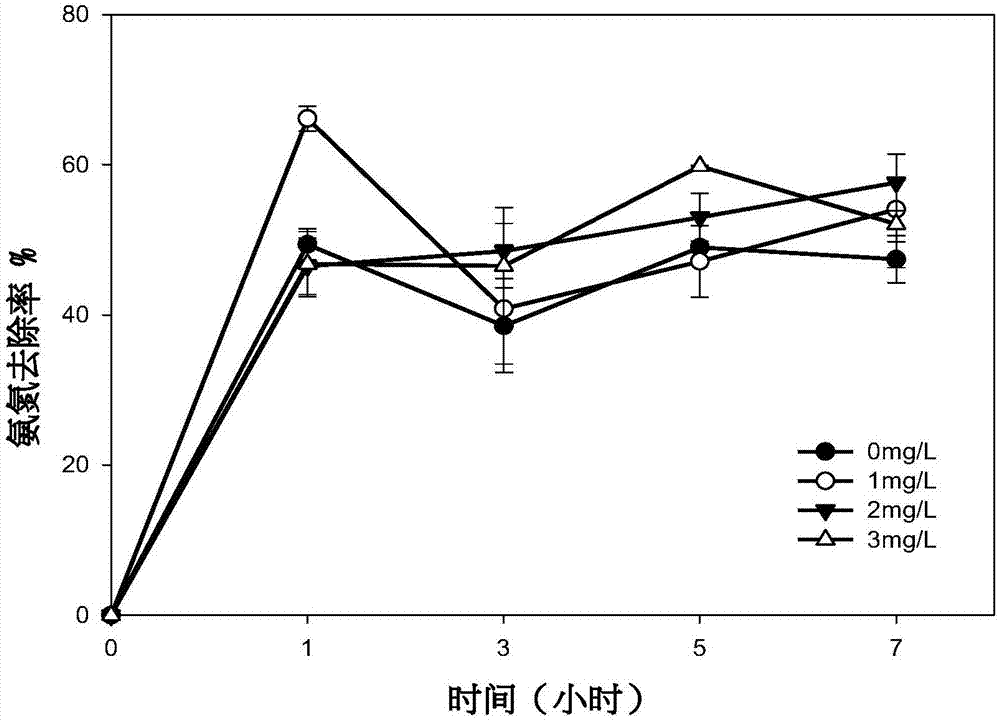

[0031] Embodiment 1 sequencing batch experiment

[0032] The raw materials are taken from the fermented pig manure that has been in stable operation for 200 days, and the fermentation method is a conventional method. The medium temperature R1 (37°C) and high temperature R2 (55°C) CSTR reactors were tested in a water bath shaker at 37 and 55°C. The effects of temperature, pH, organic acid and initial ammonia nitrogen concentration on the removal efficiency of ammonia nitrogen by MAP reaction were studied before and after. The specific treatment conditions of the experiment are shown in Table 1. In the exploratory experiments on the influence of the following 4 conditions, the VS in the total mixture was all in the range of 65% to 70%.

[0033] Table 1. Exploration experiment settings of 4 conditions influencing factors

[0034]

[0035] Specific implementation: (Taking the influence of temperature variables on MAP reaction in anaerobic fermentation broth as an example) tak...

Embodiment 2

[0041] Embodiment 2 semi-continuous anaerobic fermentation experiment

[0042] Take the crushed pig manure for 350 days of anaerobic fermentation. The first stage is the start-up stage. Both R1 and R2 start to operate at OLR1g.VS / L.d and 37°C. According to the gas production, pH and other indicators to observe the stability of the reactor, raise the temperature of the high-temperature reaction tank (37-55°C) and increase the load at the same time

[0043] (1-3g.vs / L.d). After ramping up to target temperature and load and reactor stabilization for a period of time

[0044] (0-183 days) start adding ammonium salt (NH 4 Cl), so that the total ammonia nitrogen (TAN) concentration is 1000, 2000, 3000, 4000mg / L until obvious ammonia suppression occurs. Observe that the measured indicators such as pH, VFA / TIC, methane yield, biogas composition, etc. have decreased or changed significantly, and magnesium salt (Mg 2 Cl 6H 2 O), phosphorus salt (Na 2 HPO 4 12H 2 O, K 2 HPO 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com