Preparing method of water system capacitor battery negative electrode

A technology for capacitor cells and negative electrode sheets is applied in the field of preparation of negative electrode sheets for water-based capacitor batteries, and can solve the problems of difficulty in meeting the quality requirements of auto parts, low flexibility and gloss of polar sheets, uneven dispersion of water-based mixed emulsions, and the like. It is suitable for large-scale promotion and application, omitting the pulping process, and improving the effect of the operating environment of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

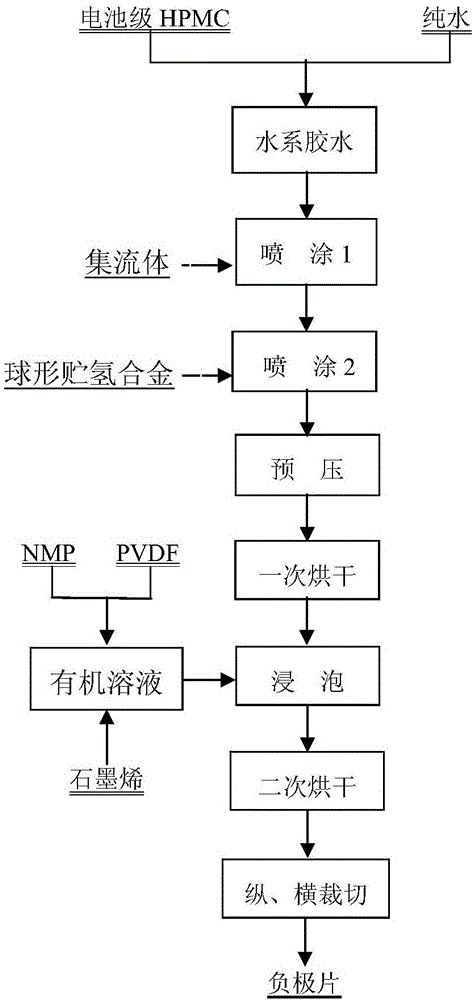

[0029] A kind of preparation method of water-system capacitance battery negative plate, such as figure 1 As shown, specifically:

[0030] a. Use HPMC and pure water to configure water-based glue, and use NMP, graphene and PVDF to configure organic solutions;

[0031] Preparation of water-based glue: Add battery-grade HPMC into pure water, stir for 2 hours under normal pressure, and then leave it statically at room temperature for 1 hour. 1%.

[0032] Preparation of organic solution: Add battery-grade PVDF into NMP liquid, stir at normal pressure for 3 hours, detect that PVDF is completely dissolved, and after there is no visible white powder, add graphene, and stir at normal pressure for 3 hours. Before use, vacuum defoaming was carried out 0.5h in advance to prepare an organic solution, wherein the content of graphene was 0.1%, and the content of PVDF was 1%.

[0033] b. The copper mesh current collector used for the negative electrode is pre-sprayed with water-based glue,...

Embodiment 2

[0036] A kind of preparation method of water-system capacitance battery negative plate, such as figure 1 As shown, specifically:

[0037] a. Use HPMC and pure water to configure water-based glue, and use NMP, graphene and PVDF to configure organic solutions;

[0038] Preparation of water-based glue: Add battery-grade HPMC into pure water, stir for 4 hours under normal pressure, and then leave it statically at room temperature for 2 hours. %.

[0039] Preparation of organic solution: Add battery-grade PVDF into NMP liquid, stir at normal pressure for 6 hours, detect that PVDF is completely dissolved, and after there is no visible white powder, add graphene in batches, stir at normal pressure, and accumulate the stirring time 6h, the stirring is completed, and before formal use, vacuum defoaming is carried out 2 hours in advance to obtain an organic solution, wherein the content of graphene is 1%, and the content of PVDF is 2.5%.

[0040] b. The steel belt current collector use...

Embodiment 3

[0043] A kind of preparation method of water-system capacitance battery negative plate, such as figure 1 As shown, specifically:

[0044] a. Use HPMC and pure water to configure water-based glue, and use NMP, graphene and PVDF to configure organic solutions;

[0045] Preparation of water-based glue: Add battery-grade HPMC into pure water, stir at normal pressure for 3 hours, and then leave it statically at room temperature for 1.5 hours. 2.5%.

[0046] Preparation of organic solution: Add battery-grade PVDF into NMP liquid, stir at normal pressure for 4 hours, detect that PVDF is completely dissolved, and after there is no visible white powder, add graphene in batches, stir at normal pressure, and accumulate the stirring time 5h, the stirring is completed, and before formal use, vacuum defoaming is carried out 1h in advance to obtain an organic solution, wherein the content of graphene is 0.5%, and the content of PVDF is 1.5%.

[0047] b. The nickel foam current collector u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com