Stuffing device and method capable of eliminating air in stuffed food

A technology for stuffing and food, which is applied in food science, dough processing, baking, etc. It can solve the problems of large size, high cost, product cavitation, etc., and achieve the effect of simple structure and principle, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

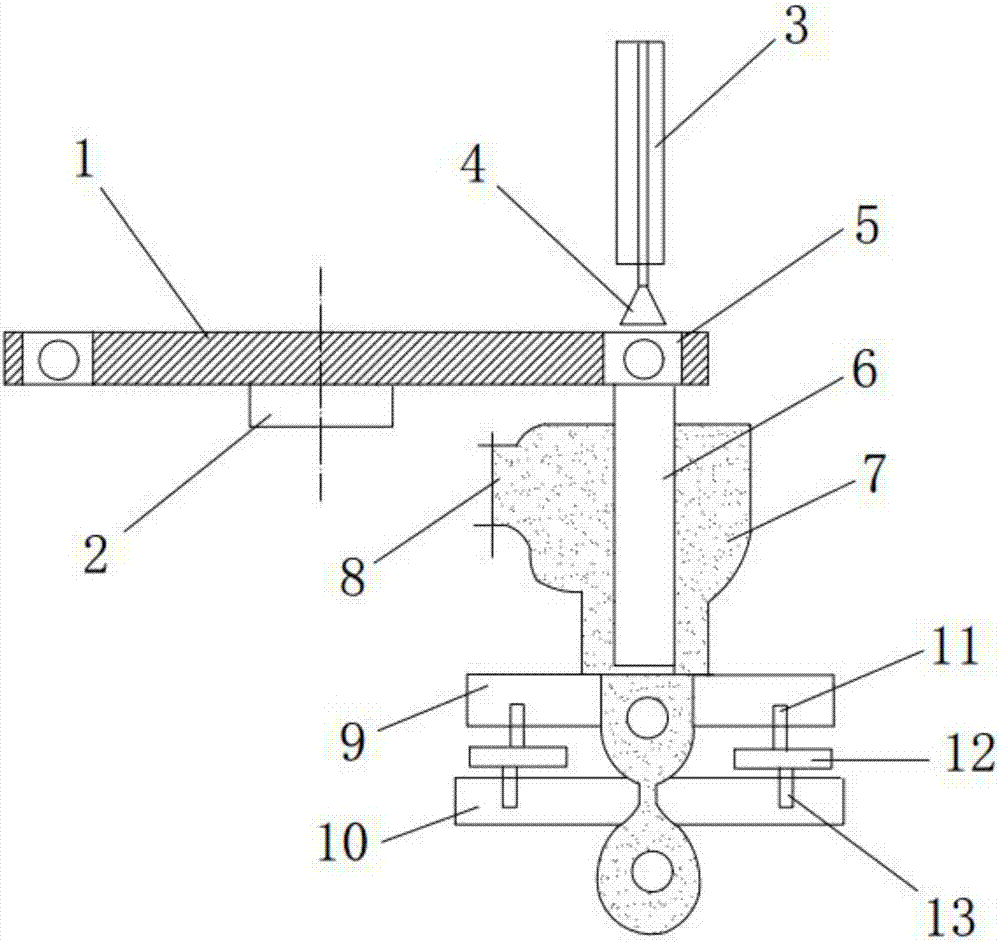

Embodiment 1

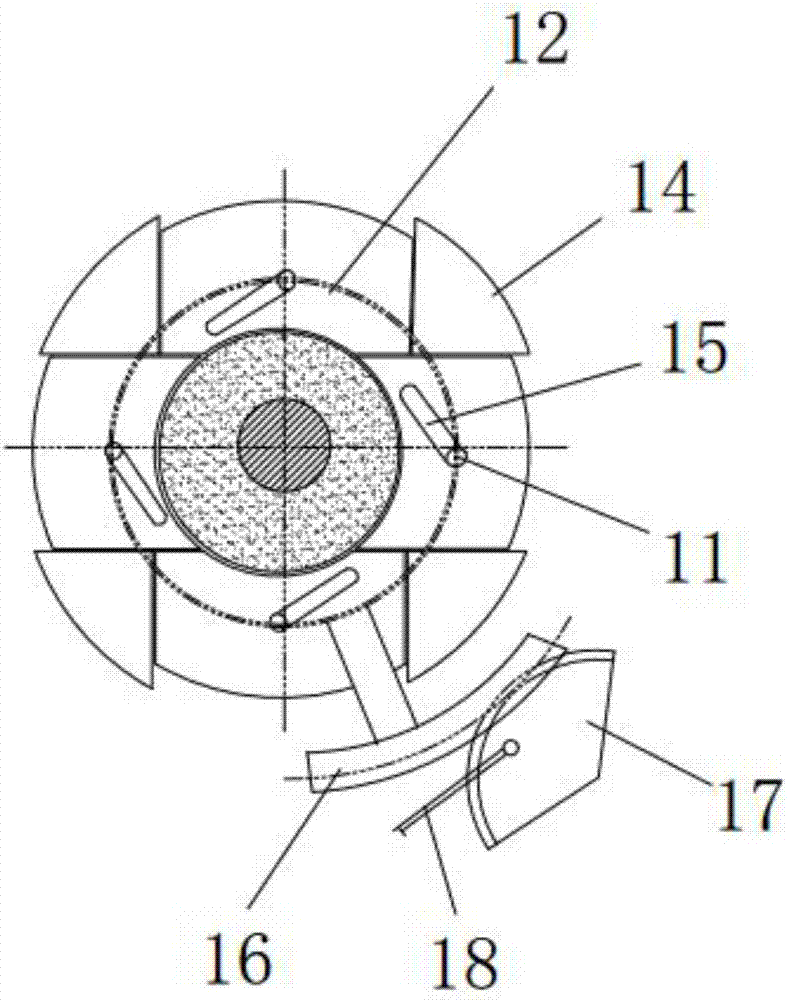

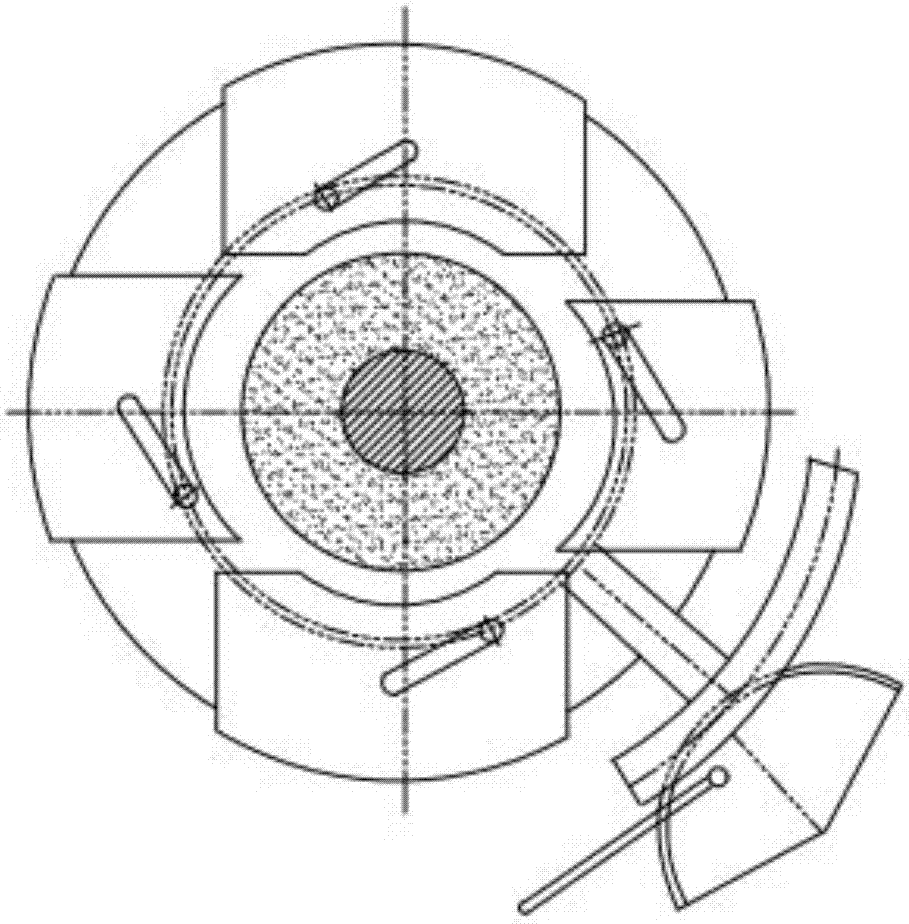

[0042] Such as figure 2 , image 3As shown, the extrusion die is composed of four square sliders, and the inner walls of the sliders are arcs that cooperate with each other. When the sliders slide inward, the inner walls can be connected to each other and form a circle, which is convenient for extruding the material into a cylinder. shape.

[0043] When the driving ring rotates to the pole ( figure 2 ), the four sliders are all close to the center to form a circular closed space, the air is discharged after the stuffing is squeezed, and it becomes a semi-finished product waiting to be cut and formed;

[0044] When the driving ring reverses to the pole ( image 3 ), the four sliders all slide outwards, the middle of the extrusion die is vacant, and the columnar material containing egg yolk passes therethrough.

Embodiment 2

[0046] Such as Figure 4 , Figure 5 As shown, the extrusion die is composed of six trapezoidal sliders; when the drive ring rotates to the pole ( Figure 4 ), the six sliders are all close to the center to form a hexagonal closed space, the air is discharged after the filling is squeezed, and it becomes a semi-finished product waiting to be cut and formed;

[0047] When the driving ring reverses to the pole ( Figure 5 ), the six sliders all slide outwards, the middle of the extrusion die is vacant, and the columnar material containing egg yolk passes therethrough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com