Fixture for ensuring accuracy of tests on chip-type ultra-low resistance product

A technology for product testing and accuracy, applied in the parts of electrical measuring instruments, measuring devices, measuring electrical variables, etc., can solve problems such as test inaccuracy, increase repeated measurement accuracy, improve test accuracy, and reduce scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

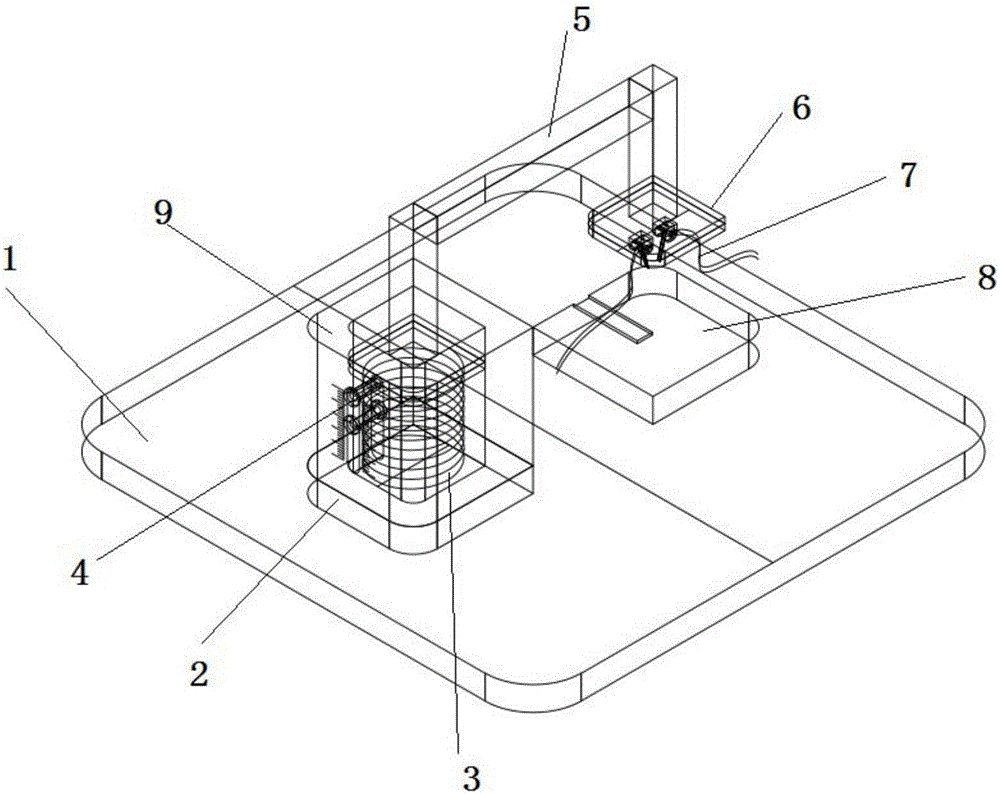

[0018] Such as figure 1 As shown, a fixture for testing the accuracy of chip-type ultra-low resistance products, including base 1, limit table 2, spring 3, upper and lower limit bolts 4, connecting arm 5, probe plate 6, four-wire probe 7 and a bearing platform 8, the base 1 is provided with a limiting platform 2 and a bearing platform is arranged side by side with the limiting platform 2, the bearing platform is provided with a groove, and the limiting platform 2 is provided with a 2 bearing platforms 8 of equal size; the inside of the bearing platform 8 is hollow, one side of the bearing platform 8 is provided with upper and lower limit bolts 4, and a spring 3 is arranged inside; the top of the bearing platform 8 is provided with a connecting arm 5, One end of the connecting arm 5 penetrates into the inside of the carrying platform 8 and is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com