Nondestructive testing method for texture quality in processes of turbot frying, water boiling, steaming and water-resisting cooking

A technology for non-destructive testing and turbot, which is applied in the field of non-destructive testing of texture quality in the process of frying, steaming, boiling, and boiling of turbot, can solve the problem of excessive hardening of turbot, poor taste, etc. There are problems such as raw fishy flavor, which can improve the detection speed, the value is accurate, and the original shape can be maintained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

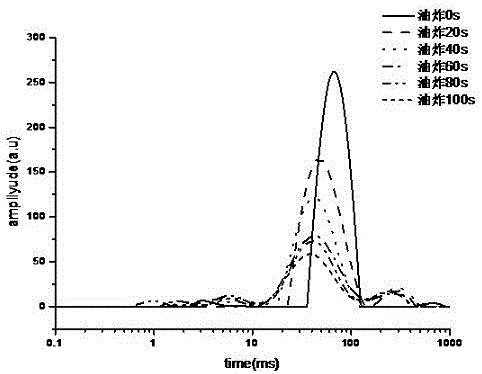

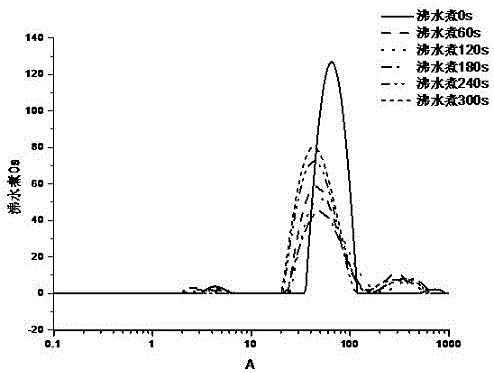

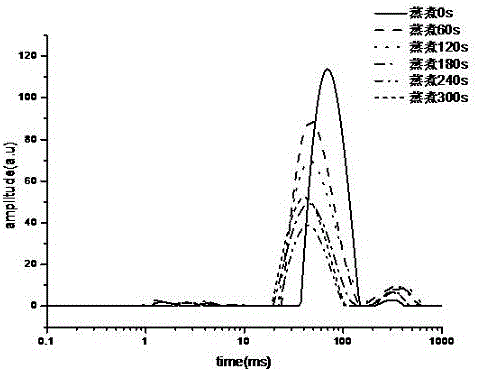

[0030] Embodiment 1, such as Figure 1 to Figure 4 As shown in Table 1 to Table 4, remove the head, skin, viscera and scales of the fresh turbot, and clean the blood and mucus, and fry the turbot at different time points, boil, steam, There are four processes of boiling in water. The time points selected for recording in this embodiment are frying: 0s, 20s, 40s, 60s, 80s, 100s; boiling, steaming, boiling in water: 0s, 60s, 120s, 180s, 240s, 300s, in actual application, the time interval can be adjusted according to the needs, and the transverse relaxation map data of more time points can be measured to improve the accuracy of the estimated value in the later stage; Low-field nuclear magnetic resonance detection was carried out on the turbot obtained from the four processes of making and boiling in water. The detection parameters were set as: 90-degree pulse width P1: 13 μs, 180-degree pulse width P2: 26 μs, and repeated sampling waiting time Tw: 1600ms- 2000ms, analog gain RG...

Embodiment approach 2

[0032] Embodiment 2, such as Figure 5 , as shown in Table 13, remove the head, skin, viscera and scales of fresh and live turbot, and clean the blood and mucus, heat commercially available quality sunflower oil until the oil temperature reaches 180°C, and wait until the oil temperature is stable Finally, fry the turbot for 50s; use low-field nuclear magnetic equipment (NMI20-030H-I) to detect the processed turbot samples, and the detection parameters are set as: 90-degree pulse width P1: 13μs, 180-degree pulse width P2: 26μs, resampling waiting time Tw: 1600ms-2000ms, analog gain RG1: [10 to 20, all integers], digital gain DRG1: [2 to 5, all integers], Preamplifier gain PRG: [1, 2, 3], NS: 4, 8, 16, NECH: 1000, receiver bandwidth SW: 200-500KHz, control parameter RFD of start sampling time: 0.02-0.05ms, time delay DL1: 0.1-0.5ms, and then use the one-dimensional inverse Laplace algorithm as the transverse relaxation time T2 inversion algorithm, the number of iterations: betw...

Embodiment approach 3

[0033] Embodiment 3: Remove the head, skin, viscera and scales of fresh turbot, clean the blood and mucus, heat the tap water to boiling, the water temperature is about 99-101°C, and treat the turbot after the water temperature is stable. Boil in water for 150s; use low-field NMR equipment (Shanghai Numei Electronic Technology, NMI20-030H-I) to detect the processed turbot samples, and the detection parameters are set as: 90 degrees pulse width P1: 13μs, 180 degrees Pulse width P2: 26μs, re-sampling waiting time Tw: 1600ms-2000ms, analog gain RG1: [10 to 20, all integers], digital gain DRG1: [2 to 5, all integers], preamplifier gain PRG: [1, 2, 3], NS: 4, 8, 16, NECH: 1000, receiver bandwidth SW: 200-500KHz, control parameter RFD of start sampling time: 0.02-0.05ms, delay DL1: 0.1-0.5ms , and then use the one-dimensional inverse Laplace algorithm as the transverse relaxation time T2 inversion algorithm, the number of iterations: between 100,000 and 10 million times, preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com