Two-dimensional layered lithium nickel phosphate positive electrode material and preparation method

A two-dimensional layered, positive electrode material technology, applied in battery electrodes, secondary batteries, electrical components, etc., can solve the problems of low ion diffusion rate and electronic conductivity, unsatisfactory effect, etc., and achieves simple preparation process and electrical conductivity. Improved, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

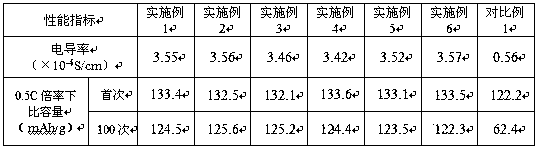

Examples

Embodiment 1

[0037](1) Use biomass resources as raw materials and ionic liquid as template agent. After mixing, heat it in a water bath at 55°C while stirring with a glass rod for 20 minutes, then transfer it to a polytetrafluoroethylene-lined reactor and pour it into the Ionized water and mixed evenly, then put the reaction kettle into the muffle furnace, heated to 185°C, and reacted at constant temperature for 7 hours. After the reaction, the reaction kettle was cooled to room temperature, and finally filtered, washed and dried to obtain a dark brown carbon product; The biomass resource is glucose; the ionic liquid is 1-butyl-3-methylimidazolium chloride;

[0038] Among them, the mass ratio of biomass resource, ionic liquid and deionized water is 1:4.5:9;

[0039] (2) Put the dark brown carbon product obtained in step (1) into a tubular calcination furnace, and calcine it under an argon atmosphere, remove the template agent, and obtain a carbon material with a two-dimensional layered str...

Embodiment 2

[0046] (1) Using biomass resources as raw materials and ionic liquid as a template, after mixing, heat it in a water bath at 63°C while stirring with a glass rod for 20 minutes, then transfer it to a polytetrafluoroethylene-lined reactor and pour it into Ionized water and mixed evenly, then put the reaction kettle into the muffle furnace, heated to 195°C, and reacted at a constant temperature for 5 hours. After the reaction, the reaction kettle was cooled to room temperature, and finally filtered, washed and dried to obtain a dark brown carbon product; The biomass resource is chitosan; the ionic liquid is l-butyl-3-methylimidazolium hexafluorophosphate;

[0047] Among them, the mass ratio of biomass resource, ionic liquid and deionized water is 1:5.5:11;

[0048] (2) Put the dark brown carbon product obtained in step (1) into a tubular calcination furnace, and calcine it under an argon atmosphere, remove the template agent, and obtain a carbon material with a two-dimensional l...

Embodiment 3

[0055] (1) Use biomass resources as raw materials and ionic liquid as template agent. After mixing, heat it in a water bath at 57°C while stirring with a glass rod for 20 minutes, then transfer it to a polytetrafluoroethylene-lined reactor and pour it into Ionized water and mixed evenly, then put the reaction kettle into the muffle furnace, heated to 188°C, and reacted at constant temperature for 7 hours. After the reaction, the reaction kettle was cooled to room temperature, and finally filtered, washed and dried to obtain a dark brown carbon product; The biomass resource is straw; the ionic liquid is 1-butyl-3-methylimidazolium chloride;

[0056] Among them, the mass ratio of biomass resource, ionic liquid and deionized water is 1:5:11;

[0057] (2) Put the dark brown carbon product obtained in step (1) into a tubular calcination furnace, and calcine it under an argon atmosphere, remove the template agent, and obtain a carbon material with a two-dimensional layered structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com