Crack preventing reinforced concrete wall structure and construction method thereof

A reinforced concrete wall and reinforced concrete technology, applied to walls, building components, building structures, etc., can solve problems such as ineffective anti-cracking effects, avoid curing temperature changes, improve lateral stiffness and crack resistance, and early high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

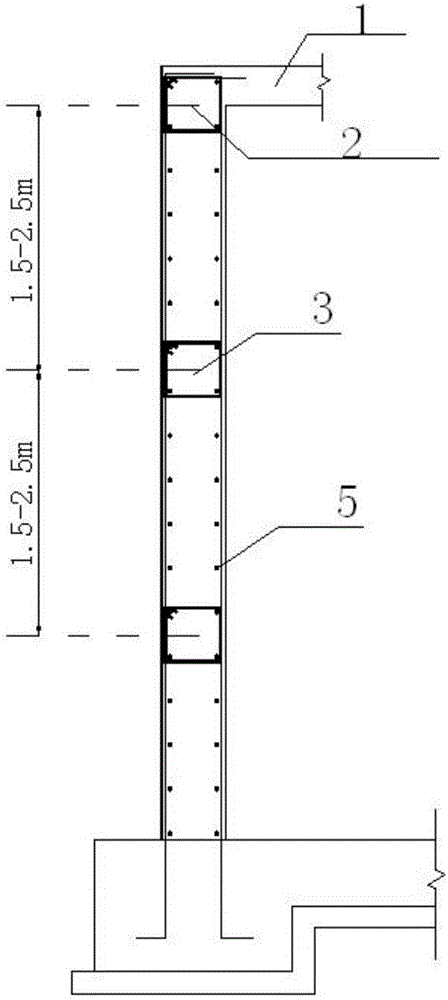

[0023] A reinforced concrete wall structure for preventing cracking. The reinforced concrete wall is a vertical cantilever structure, and double rows of steel mesh sheets 5 are arranged inside.

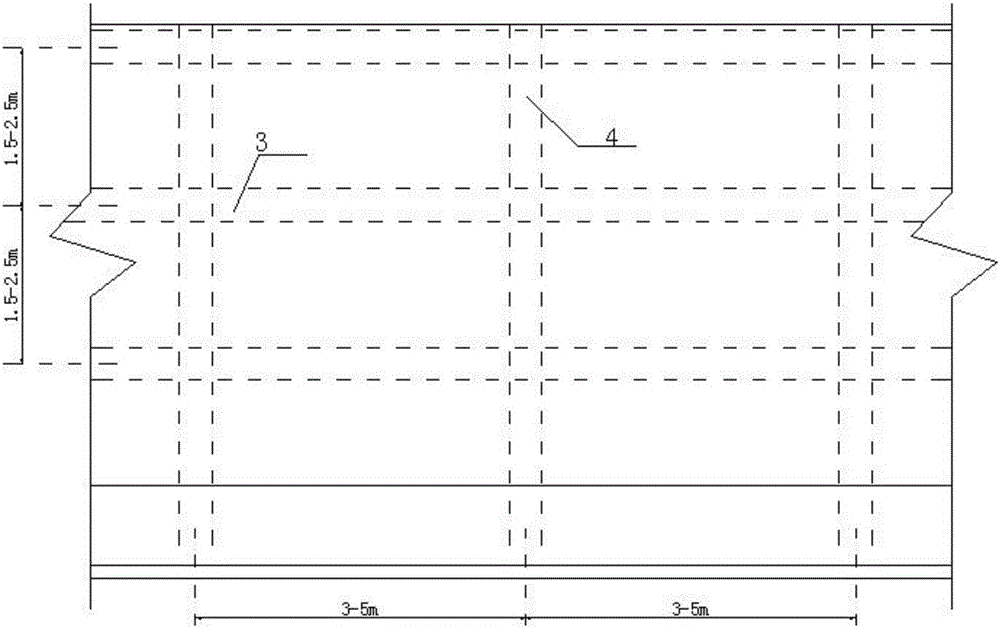

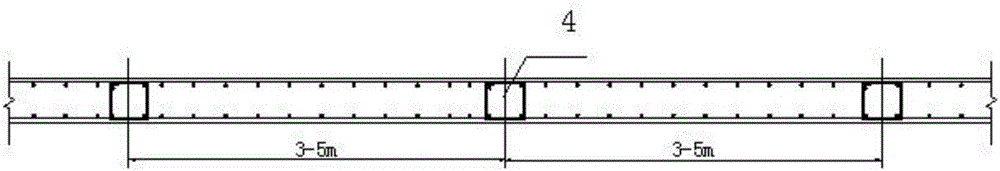

[0024] When the wall is a vertical cantilever structure and only connected to the beam 1, set a hidden beam 2 on the top of the wall, and install the hidden beams at a distance of 1.5m to 2.5m along the vertical direction, and at a distance of 3.0m to 5.0m along the vertical direction Set dark column 4. When the top of the wall is in contact with the slab, there is no need to install concealed beams 2 on the top of the wall, only concealed beams 3 are installed at intervals of 1.5m to 2.5m along the vertical direction, and concealed columns 4 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com