Adhesive lining cloth for coated fabric

A technology of bonding interlining and coating, applied in textile and papermaking, fiber processing, fiber repelling to liquid, etc., can solve the problems of poor adhesion of coated fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

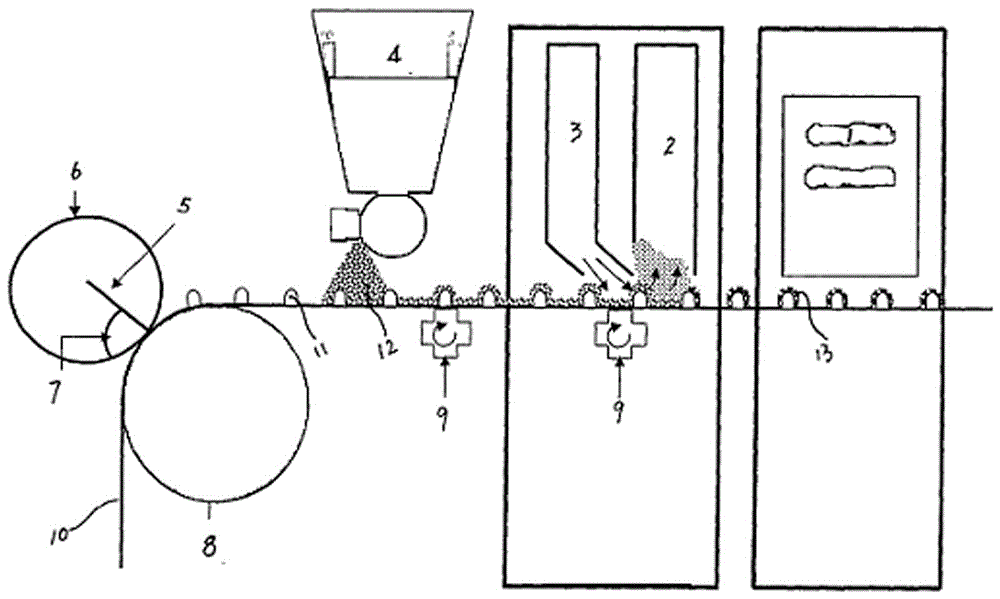

Method used

Image

Examples

Embodiment Construction

[0040] The invention provides a fusible interlining for coated fabrics, comprising base fabric and double-point coating, wherein:

[0041] The base fabric adopts 30D or 50D woven polyester plain weave;

[0042] The two-point coating adopts a thermoplastic adhesive resin;

[0043] The base fabric is pretreated, and the double-point coating is formed on the surface of the base fabric in a point-like distribution manner, finally forming the fusible interlining fabric for the coated fabric.

[0044] In one embodiment, the base cloth is made of polyester low elastic yarn.

[0045] In one embodiment, the thermoplastic adhesive resin is selected from TPU (polyurethane), PES (polyester), PVC or PA (polyamide). Specifically, 90% TPU rubber powder + 10% PA hot melt rubber powder is used for PU coated fabrics; PVC rubber powder is used for PVC coated fabrics; PES rubber powder is used for PE coating.

[0046] In one embodiment, the pretreatment of the base cloth includes scouring and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com