Tung oil coated degradable mulching film

A technology for degrading mulch and tung oil, which can be used in coatings, plant protection, applications, etc. It can solve the problems of oxygen deficiency, water vapor accumulation, and difficulty in recycling, and achieve the effects of reducing recycling costs, improving water storage capacity, and preventing water mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Polypropylene 10g / m 2 , 2 coats of tung oil.

[0044] For the cultivation of flue-cured tobacco

[0045] Steps: (1) raising seedlings; (2) transplanting; transplanting into the soil, using a single ridge planting; (3) fertilizing and watering; (4) pest control; (5) topping and wiping; (6) mature picking ;

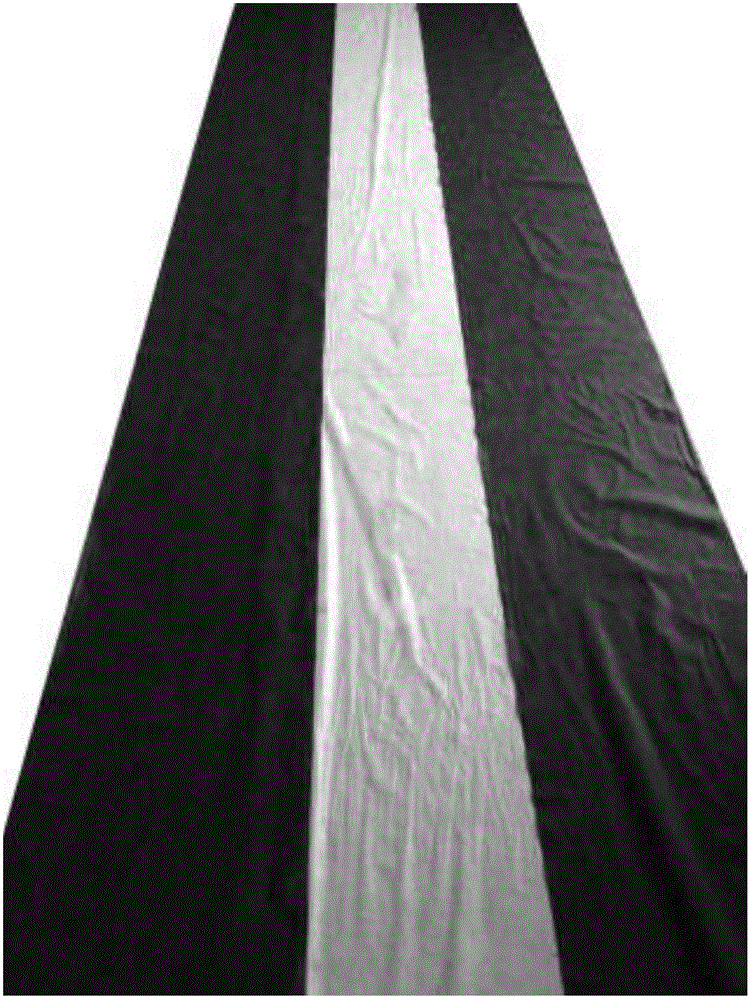

[0046]Transplanting under the film is adopted, in which, the white shell degradable plastic film is covered on the growth area of the tobacco plant, and the black new degradable plastic film is covered on both sides of the growth area to prevent the growth of weeds.

[0047] The steps of raising seedlings, transplanting, fertilizing and watering, controlling diseases and insect pests, topping and wiping branches, and mature picking are carried out according to the general agricultural work.

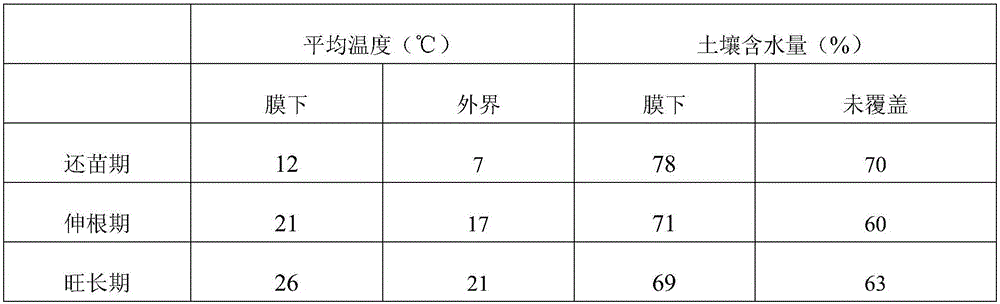

[0048] The heat preservation and water retention effects are tested in the following table:

[0049]

[0050] After the product is covered, the tobacco plant has been b...

Embodiment 2

[0058] Plastic film cultivation for peanuts, polypropylene 10g / m 2 , 2 layers of tung oil coating, calcium carbonate 2g / m 2 .

[0059] It is very important to grasp the sowing time. Peanuts are sown from May 15th to 25th, and mulched peanuts can be sown from May 10th to 15th. Within 5 days, the daily average ground temperature of the 5-10 cm plow layer is stable and exceeds 12°C before sowing, and the plastic film peanut can increase the ground temperature; the sowing is uniform, and the plastic film is close to the ridge surface. Throw two shovels of soil every 2-3 meters to prevent the wind from lifting the membrane. Film-mulched peanuts cannot be intertilled, and weeding must be sprayed before covering the film.

[0060] Others are the same as ordinary planting methods.

[0061] Peanut mulching can regain the effective accumulated temperature of 230-270°C. According to the above method, the yield of peanuts per hectare is 1000-2000 kg, that is, the mulching peanuts are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com