Environment-friendly multifunctional cleaning agent for removing oil and rust and preventing rust and cleaning application method

An environment-friendly cleaning agent technology, which is applied in the field of environment-friendly multifunctional cleaning agents for wax removal, oil removal, rust removal, and anti-rust, can solve the problems of unstable cleaning quality, increased cleaning cost, manual scrubbing, etc., and achieve energy saving and cleaning costs , avoid oxidation or rust, and improve the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Each component is selected according to the following weight content: 0.5-5% of compound organic chelating agent, 5-25% of surfactant, 0.5-6% of stabilizer, 5-15% of cleaning aid, and 49-89% of water. The compound organic chelating agent includes one or more compositions in sodium citrate, sodium gluconate, and potassium phytate; the surfactant includes cocamidopropyl betaine, isooctyl alcohol polyoxyethylene ether mono Phosphate ester, isomeric tridecyl alcohol polyoxyethylene ether, lauryl polyoxyethylene ether, isomeric decanol polyoxyethylene ether, triethanolamine oleic acid soap; the stabilizer includes methyl One or more compositions of benzotriazepine, isononanoic acid, and monoethanolamine; the cleaning aid includes one or more of potassium carbonate, potassium bicarbonate, and sodium dimethylbenzenesulfonate combination.

[0035] The cleaning efficiency under different formulations was tested by changing the ratio of each component within this range, and the ...

Embodiment 2

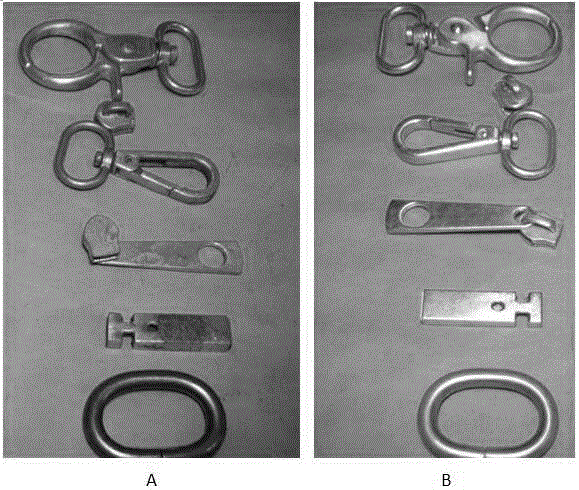

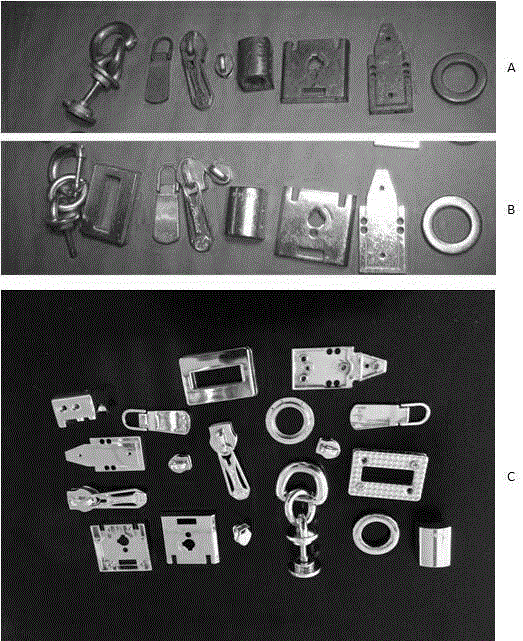

[0047] Based on Example 1, the environment-friendly dewaxing, degreasing, rust and anti-rust multifunctional cleaning agent prepared by formula No. 4, this Example 2 provides a cleaning application method (see figure 1 ), including the following steps: a fully automatic cleaning line consisting of 3 cleaning tanks, 3 rinsing tanks, and an air knife drying system; the parameters involved are as follows: (1) Cleaning: 1#, 2#, 3# are cleaning The tank adopts the continuous cleaning method of three cleaning tanks combining immersion cleaning and ultrasonic cleaning, that is, the 1# cleaning tank adopts immersion cleaning; the 2# and 3# cleaning tanks adopt ultrasonic cleaning. It not only cleans the workpiece efficiently and thoroughly, but also reduces the investment cost of the equipment; (2) Rinsing: 4#, 5#, and 6# are rinsing tanks, using ultrasonic waves, water circulation, and hot water. Three different rinsing methods, that is, 4# rinsing tanks Ultrasonic water is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com