Early-strength type mining sealing material

A sealing material and early-strength technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems that the early strength is difficult to meet the use requirements, the length of the sealing hole is difficult to control, and the setting time is long, etc., to achieve faster The process of hydration reaction, gas drainage is durable and stable, and the effect of early strength is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

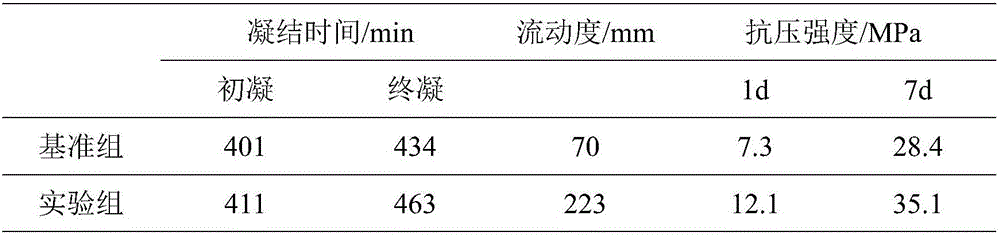

[0026] Water: 40%, calcium thiocyanate: 0.2%, triethanolamine: 0.03%, polycarboxylate superplasticizer: 0.1%. Mix the above materials and stir well before use. When in use, the prepared material is mixed with Portland cement clinker to form a slurry. The experimental results are shown in Table 1.

[0027] Table 1 Experimental results of sealing material properties

[0028]

[0029] It can be seen from Table 1 that compared with the reference group, the fluidity of the experimental group has been greatly improved, which can perfectly meet the needs of long-distance sealing; the setting time is slightly longer than that of the reference group; the 1-day compressive strength is higher than that of the reference group 66% improvement and 24% improvement in 7-day compressive strength. Its various performance indicators can fully meet the requirements for the use of sealing materials.

Embodiment 2

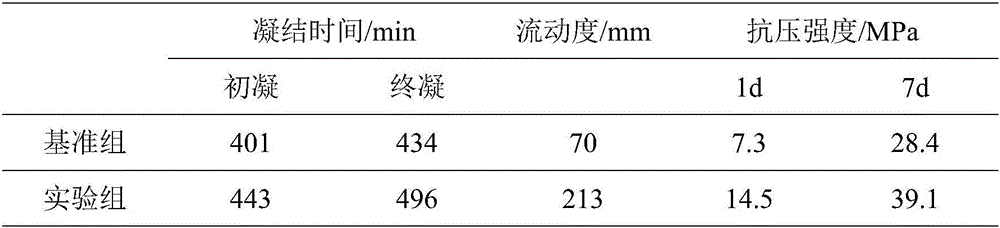

[0031] Water: 40%, calcium thiocyanate: 0.1%, calcium fluoroaluminate: 4%, triethanolamine: 0.02%, polycarboxylate superplasticizer: 0.1%. Mix the above materials and stir well before use. When in use, the prepared material is mixed with Portland cement clinker to form a slurry. The test results are shown in Table 2.

[0032] Table 2 Experimental results of sealing material properties

[0033]

[0034] It can be seen from Table 2 that the initial setting time of the experimental group is 443min, the final setting time is 496min; the fluidity is 213mm; the 1-day compressive strength is 14.5MPa, the 7-day compressive strength is 39.1MPa, and the 1-day compressive strength is higher than that of the reference group 99%, 7-day compressive strength increased by 38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com