A kind of biodegradable modified polylactic acid adhesive tape and preparation method thereof

A polylactic acid and modification technology, applied in the field of modified polylactic acid tape and its preparation, can solve the problems of less degradable tapes and less product launches, and achieve the effects of stable heat resistance, improved related performance, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

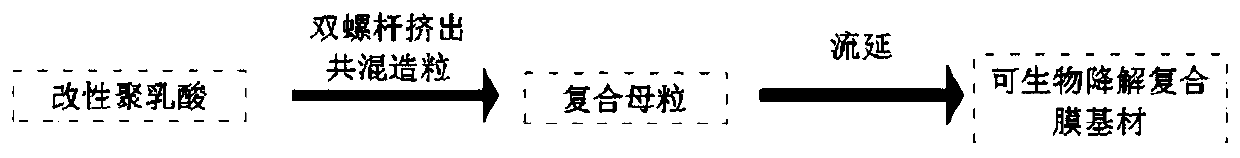

Method used

Image

Examples

Embodiment 1

[0036] Coating modification on the surface of the substrate layer [w (PBSA) = 10%, w (TPS) = 20%, w (nanocellulose) = 1% (all relative to the quality of PLA)] with a film thickness of 20 μm Acrylic pressure-sensitive adhesive, the amount of adhesive is 20g / m2, to obtain a film coated with adhesive.

[0037] In the modified acrylate pressure-sensitive adhesive, w(GH)=0.7%, w(KH-570)=0.2% (all relative to the total monomer mass);

[0038] The film tape coated with the adhesive was baked in an oven at 80°C for 4 minutes to obtain a completely degradable modified polylactic acid tape.

Embodiment 2

[0040] Coating modification on the surface of the substrate layer [w (PBSA) = 10%, w (TPS) = 10%, w (nanocellulose) = 1% (all relative to the quality of PLA)] with a film thickness of 20 μm Acrylic pressure-sensitive adhesive, the amount of adhesive is 40g / m2, to obtain a film coated with adhesive.

[0041] In the modified acrylate pressure-sensitive adhesive, w(GH)=0.7%, w(KH-570)=0.3% (all relative to the total monomer mass);

[0042] The film tape coated with the adhesive was baked in an oven at 80°C for 4 minutes to obtain a completely degradable modified polylactic acid tape.

Embodiment 3

[0044] Coating modification on the surface of the substrate layer [w (PBSA) = 20%, w (TPS) = 20%, w (nanocellulose) = 2% (all relative to the quality of PLA)] with a film thickness of 20 μm Acrylic pressure-sensitive adhesive, the amount of adhesive is 20g / m2, to obtain a film coated with adhesive.

[0045] In the modified acrylate pressure-sensitive adhesive, w(GH)=0.7%, w(KH-570)=0.3% (all relative to the total monomer mass);

[0046] The film tape coated with the adhesive was baked in an oven at 80°C for 4 minutes to obtain a completely degradable modified polylactic acid tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com