Conductive ink composition with self-repair functions, method for preparing conductive ink composition and application thereof

A conductive ink, self-healing technology, used in applications, inks, household appliances, etc., can solve problems such as property loss, shortening service life, waste of resources, etc., and achieve the effect of increasing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a conductive ink composition with self-repair function, the steps comprising:

[0029] 1) Heat 1g of polytetrahydrofuran (PTMEG2000) to 80°C, keep the vacuum below 0.1 MPa, dehydrate for 1h, cool down to 50°C, add 0.222g of isophorone diisocyanate and 10g of N,N-dimethylformamide , stirred at 100 °C for 6 h, then cooled to 50 °C;

[0030] 2) Add 0.115g of 4,4-diaminodiphenyl disulfide and 0.009g of hyperbranched polyamidoamine to the system in step 1), and react at 100 °C for 5 h to obtain self-sustainable polyamide containing disulfide bonds and hyperbranched structure. repaired polymers;

[0031] 3) The polymer in step 2) was uniformly mixed with 2.6 g of a 50% silver trifluoroacetate solution in N,N-dimethylformamide to obtain a conductive ink composition with a self-healing function.

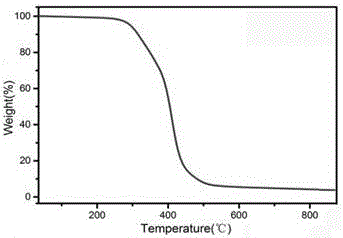

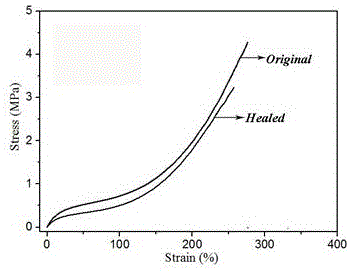

[0032] Example 1 Self-healing polymer TGA curve such as figure 1 Shown; Conductive ink composition stress-strain curve such as figure 2 shown.

[0033] A...

Embodiment 2

[0035] 1) Heat 1g polytetrahydrofuran (PTMEG2000) to 80°C, keep the vacuum below 0.1 MPa, dehydrate for 1h, cool down to 50°C, add 0.111g isophorone diisocyanate, 0.125g diphenylmethylene diisocyanate and 10g Dimethylformamide, stirred and reacted at 100°C for 6 h, cooled to 50°C;

[0036] 2) Add 0.120g of 4,4-diaminodiphenyl disulfide and 0.005g of hyperbranched polyamidoamine to the system in step 1), and continue to react at 100 °C for 5 h to obtain a polyamide containing disulfide bond and hyperbranched structure. self-healing polymers;

[0037] 3) The polymer in step 2) was uniformly mixed with 1.4 g of a 50% silver trifluoroacetate solution in N,N-dimethylformamide to obtain a conductive ink composition with self-healing function.

[0038] Application: The conductive ink composition of Example 2 was written on paper with a brush, and reduced by 50 mL / L formaldehyde solution at room temperature for 20 minutes to obtain a conductive line with a conductivity of 140 S cm -...

Embodiment 3

[0040] 1) Mix 1g polyethylene glycol (M w 2000) heated to 80°C, kept the vacuum below 0.1 MPa, dehydrated for 1h, cooled to 50°C, added 0.250g of diphenylmethylene diisocyanate and 15g of N,N-dimethylformamide, stirred and reacted at 120°C 4 h, cool down to 50 ℃;

[0041] 2) Add 0.058g dithiodiethanol and 0.005g hyperbranched polyamidoamine to the system in step 1), and react at 120 °C for 4 hours to obtain a self-healing polymer containing disulfide bonds and hyperbranched structures;

[0042] 3) The polymer in step 2) was uniformly mixed with 1.4 g of a 30% silver trifluoroacetate solution in N,N-dimethylformamide to obtain a conductive ink composition with a self-healing function.

[0043] Application: The conductive ink composition of Example 3 was written on glass by a brush, and reduced by 50 mL / L formaldehyde solution at room temperature for 20 minutes to obtain a conductive circuit with a conductivity of 80 S cm -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com