High-property graphene/nylon 6 nanometer composite material and preparation method thereof

A nano-composite material, graphene technology, applied in the field of high-performance graphene/nylon 6 nano-composite material and its preparation, to achieve the effect of comprehensive performance improvement, less dosage and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of graphene / nylon 6 nanocomposite material, carry out as follows:

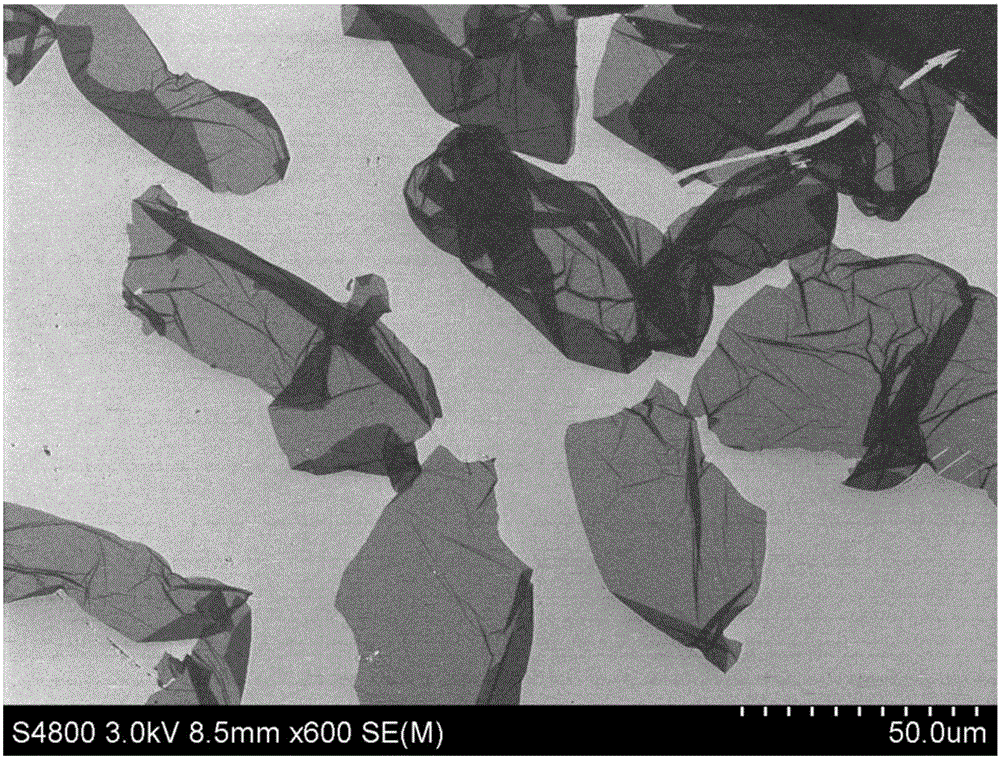

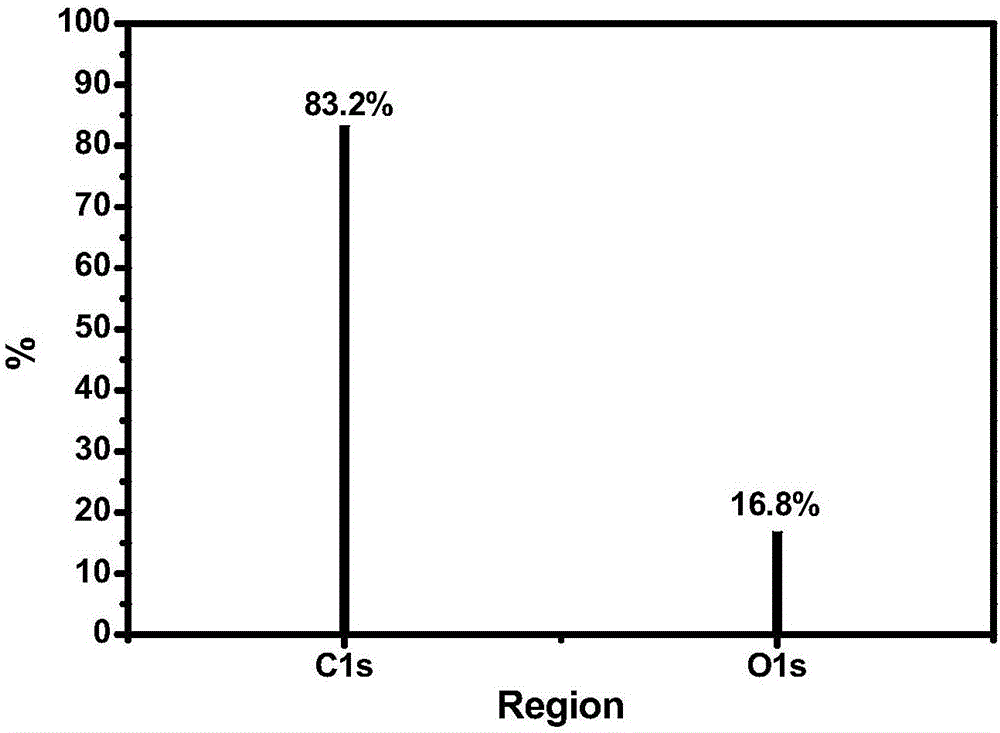

[0023] (1) Add 0.5 parts by mass of a single-layer modified graphene sheet with a lateral dimension of 3 microns and a carbon-to-oxygen ratio of 2.5 and 10 parts by mass of deionized water into the caprolactam melt of 100 parts by mass, and at 80 ° C at a high speed (300 ~500rpm) stirring and mixing to form a dispersion. The modified graphene is a single-layer graphene sheet with oxygen-containing functional groups such as carboxyl groups and hydroxyl groups on the surface.

[0024] (2) Under the protection of nitrogen, the above dispersion liquid is heated to 250-270°C in the polycondensation reactor, and reacted at 0.5-1MPa for 3 hours; then reacted under vacuum for 4 hours to obtain a polymer melt; The melted material was water-cooled and granulated to obtain a graphene / nylon 6 nanocomposite material.

[0025] The properties of the resulting graphene / nylon 6 nanocomposite are...

Embodiment 2

[0027] The preparation method of graphene / nylon 6 nanocomposite material, carry out as follows:

[0028] (1) The lateral dimension of 0.3 mass parts is 10 microns, the monolayer modified graphene sheet of carbon-to-oxygen ratio 3 and 8 mass parts deionized water are added in the caprolactam melt of 100 mass parts, under 80 ℃ high-speed (300 ~500rpm) stirring and mixing to form a dispersion. The modified graphene is a single-layer graphene sheet with oxygen-containing functional groups such as carboxyl groups and hydroxyl groups on the surface.

[0029] (2) Under the protection of nitrogen, the above dispersion liquid is heated to 250-270°C in the polycondensation reactor, and reacted at 0.5-1MPa for 3 hours; then reacted under vacuum for 4 hours to obtain a polymer melt; finally polymerized The melted material was water-cooled and granulated to obtain a graphene / nylon 6 nanocomposite material.

[0030] The properties of the resulting graphene / nylon 6 nanocomposite are shown ...

Embodiment 3

[0032] The preparation method of graphene / nylon 6 nanocomposite material, carry out as follows:

[0033](1) The lateral dimension of 0.2 mass parts is 15 microns, the monolayer modified graphene sheet of carbon-to-oxygen ratio 3.9 and 5 mass parts deionized water are added in the caprolactam melt of 100 mass parts, under 80 ℃ high-speed (300 ~500rpm) stirring and mixing to form a dispersion. The modified graphene is a single-layer graphene sheet with oxygen-containing functional groups such as carboxyl groups and hydroxyl groups on the surface.

[0034] (2) Under the protection of nitrogen, the above dispersion liquid is heated to 250-270°C in the polycondensation reactor, and reacted at 0.5-1MPa for 3 hours; then reacted under vacuum for 4 hours to obtain a polymer melt; The melted material was water-cooled and granulated to obtain a graphene / nylon 6 nanocomposite material.

[0035] The properties of the resulting graphene / nylon 6 nanocomposite are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com