Preparation method of multiplex self-repair polyurethane blended material

A self-healing, polyurethane technology, applied in the field of polyurethane material crack repair, can solve the problems of not being able to repair repeatedly, affecting normal use, and obvious bonding parts, and achieving the effects of good material performance, improved bonding ability, and high repair efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

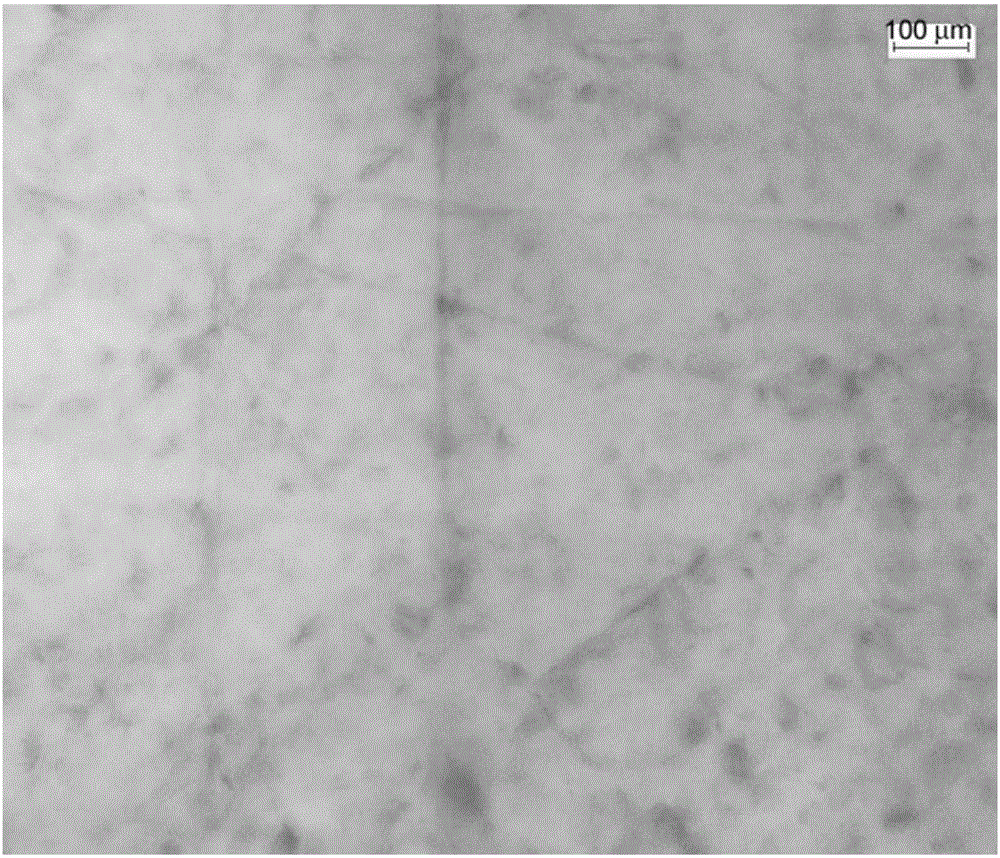

Image

Examples

preparation example Construction

[0022] The preparation method of the multiple self-healing polyurethane blend material proposed by the present invention comprises the following steps:

[0023] (1) The following monomers, initiators, polyurethane resins and solvents are mixed in mass fractions to obtain mixtures:

[0024] Monomer 10-150 parts,

[0025] Initiator 1-10 parts,

[0026] 325-500 parts of polyurethane resin;

[0027] Solvent 2400-3200 parts

[0028] Wherein the monomer is dopamine methacrylamide or dopamine acrylamide, or two kinds are mixed in any proportion; the initiator is azobisisobutyronitrile, dimethyl azobisisobutyrate, One of azodiisovaleronitrile, azobiscyclohexylcarbonitrile or benzoyl peroxide, and the solvent is N,N-dimethylformamide;

[0029] (2) Stir and mix the mixture in step (1) evenly, and carry out solution radical polymerization reaction under the protection of an inert gas, the reaction temperature is 60-70° C., and the reaction time is 20-28 hours to obtain the reactant; ...

Embodiment 1

[0037] (1) The following monomers, initiators, polyurethane resins and solvents are mixed in mass fractions to obtain mixtures:

[0038] Monomer (dopamine methacrylamide) 0.175g

[0039] Initiator (azobisisobutyronitrile) 9.0mg

[0040] Polyurethane resin 3.325g

[0041] N,N-Dimethylformamide (DMF) 17g

[0042] (2) Stir and mix the mixture in step (1) evenly, and carry out solution radical polymerization reaction under the protection of an inert gas, the reaction temperature is 60-70° C., and the reaction time is 20-28 hours to obtain the reactant;

[0043] (3) Pour the reactants of step (2) into a mold, and dry at 68°C in an inert gas environment for 40 hours until the quality remains unchanged, and a multi-self- Repair the polyurethane blend material Poly(DMA) / PU blend film, and then cut the polyurethane blend film into specifications of 50mm in length and 6mm in width.

[0044] An electronic universal testing machine was used to test the tensile strength of the sample a...

Embodiment 2

[0047] (1) The following monomers, initiators, polyurethane resins and solvents are mixed in mass fractions to obtain mixtures:

[0048] Monomer (dopamine methacrylamide) 0.35g

[0049] Initiator (azobisisobutyronitrile) 18.0mg

[0050] Polyurethane resin 3.15g

[0051] N,N-Dimethylformamide (DMF) 20g

[0052] (2) Stir and mix the mixture in step (1) evenly, carry out solution radical polymerization reaction under the protection of inert gas, the reaction temperature is 70° C., and the reaction time is 28 hours to obtain the reactant;

[0053] (3) Pour the reactants of step (2) into a mold, and dry at 68°C in an inert gas environment for 44 hours until the quality remains unchanged, and a multi-self- Repair the polyurethane blend material Poly(DMA) / PU blend film, and then cut the polyurethane blend film into specifications of 50mm in length and 6mm in width.

[0054] According to the method of Example 1, heat it in an oven at 90°C for 40 minutes or place it under an infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com