Sound absorbing material and preparation method thereof

A technology of sound-absorbing materials and collagen, which is applied in the field of composite materials to achieve the effects of strong durability, low density and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

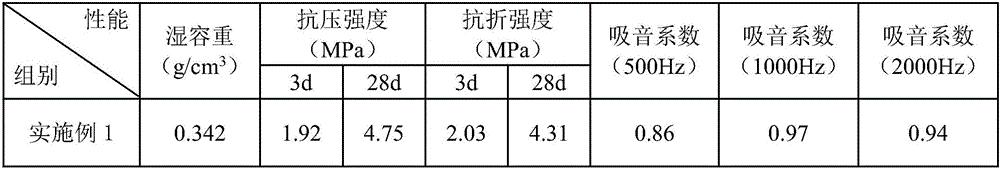

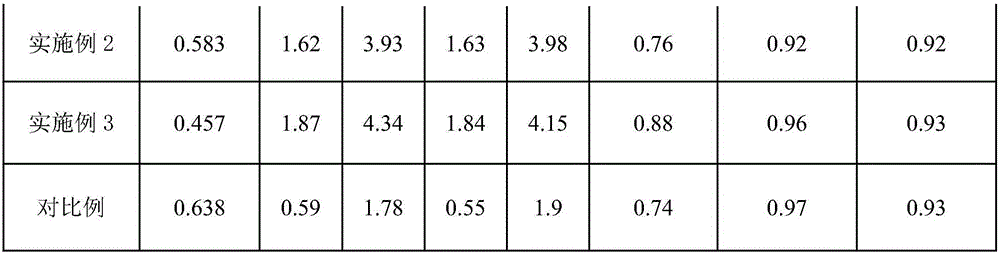

Embodiment 1

[0037] A sound-absorbing material provided in Example 1 is prepared according to the following steps:

[0038] (1) Add calcium hydroxide to the waste water of the trotter processing plant, adjust the pH value to 12, and stir to form a thick paste;

[0039] (2) Add sodium lauryl sulfate and coconut acid diacetamide to the paste described in step (1), the ratio is paste: sodium lauryl sulfate: coconut acid diacetamide The mass ratio=1:1.5:1.5, obtain blowing agent;

[0040] (3) water-quenched copper slag, cement and fly ash are mixed, and the ratio is water-quenched copper slag: cement: the mass ratio of fly ash=0.3:2:1, obtains mixture;

[0041] (4) Add water and foaming agent in the mixture, the ratio is water: foaming agent: the mass ratio of mixture=0.6:0.013:1, stir for 10min, and the rotating speed is 1000r / min to obtain foamed cement slurry;

[0042] (5) The foamed cement slurry was injected into the mold, dried at 110°C for 0.5h, and naturally cured for 72h to obtain t...

Embodiment 2

[0045] A sound-absorbing material provided in Example 2 is prepared according to the following steps:

[0046] (1) Add calcium hydroxide to the waste water of the trotter processing plant, adjust the pH value to 10, and stir to form a thick paste;

[0047](2) Add sodium lauryl sulfate and coconut acid diacetamide to the paste described in step (1), the ratio is paste: sodium lauryl sulfate: coconut acid diacetamide The mass ratio=1:1.5:1.5, obtain blowing agent;

[0048] (3) water-quenched copper slag, cement and fly ash are mixed, and the ratio is water-quenched copper slag: cement: the mass ratio of fly ash=0.05:2:1, obtains mixture;

[0049] (4) Add water and foaming agent in the mixture, the ratio is water: foaming agent: the mass ratio of mixture=0.4:0.0035:1, stir for 5min, and the rotating speed is 1500r / min to obtain foamed cement slurry;

[0050] (5) The foamed cement slurry was injected into the mold, dried at 80°C for 2 hours, and naturally cured for 72 hours to o...

Embodiment 3

[0053] A sound-absorbing material provided in Example 3 is prepared according to the following steps:

[0054] (1) Calcium hydroxide is added to the waste water of the pig's trotter processing plant, and the pH value is adjusted to 11, and stirred to form a thick paste;

[0055] (2) Add sodium lauryl sulfate and coconut acid diacetamide to the paste described in step (1), the ratio is paste: sodium lauryl sulfate: coconut acid diacetamide The mass ratio=1:1.5:1.5, obtain blowing agent;

[0056] (3) water-quenched copper slag, cement and fly ash are mixed, and the ratio is water-quenched copper slag: cement: the mass ratio of fly ash=0.15:2:1, obtains mixture;

[0057] (4) Add water and foaming agent in the mixture, the ratio is water: foaming agent: the mass ratio of mixture=0.5:0.01:1, stir for 7min, and the rotating speed is 1200r / min to obtain foamed cement slurry;

[0058] (5) The foamed cement slurry was injected into the mold, dried at 105°C for 1 hour, and naturally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com