Method for producing low-carbon Ni-Mo alloy steel by billet caster

A billet continuous casting and alloy steel technology, which is applied in the field of steelmaking and continuous casting, can solve the problems of steel breakout, internal and surface defects, etc., and achieve the effect of reducing cooling intensity and avoiding billet cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

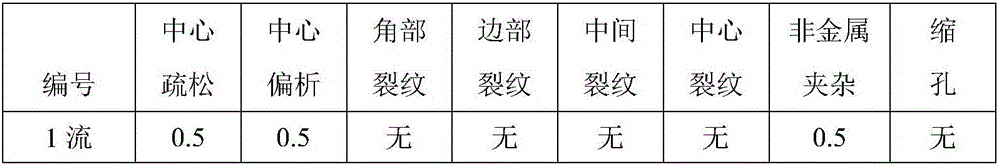

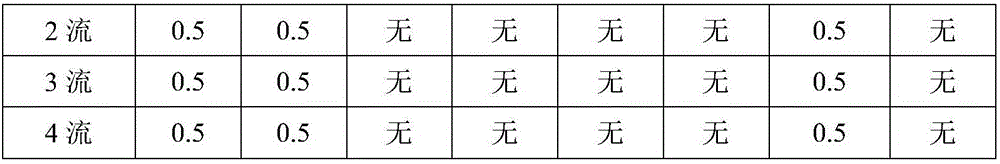

Examples

Embodiment 1

[0023] 1) The industrial production and supply of the low-carbon Ni-Mo alloy steel has been realized in the long steel production line of Shougang. The billet continuous casting machine is a 5-machine, 5-strand full-arc 150mm×150mm billet continuous casting machine. Base arc radius R10m. The main continuous casting process parameters in the production process are as follows: [P] in steel: 0.0130%, [S]: 0.0040%.

[0024] 1. Preparation before pouring:

[0025] (1) The baking temperature of the tundish is 1120°C;

[0026] (2) Both the ladle long nozzle and the crystallizer submerged nozzle are made of aluminum carbon nozzle;

[0027] 2. Protective casting measures:

[0028] (1) The tundish is filled with argon before pouring; the long nozzle is sealed with Ar;

[0029] (2) The tundish adopts carbon-free tundish covering agent; low-carbon steel special mold slag is used; mold mold slag is kept in "black slag" operation; mold slag is added frequently and less to ensure suffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com