Crystallizer with changeable cooling intensity in semicontinuous casting of aluminum alloy

A cooling intensity, semi-continuous technology, applied in the crystallizer field, can solve problems such as surface cracks, ingot cooling unevenness, etc., to achieve the effect of reducing pressure, increasing turbulent flow, and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

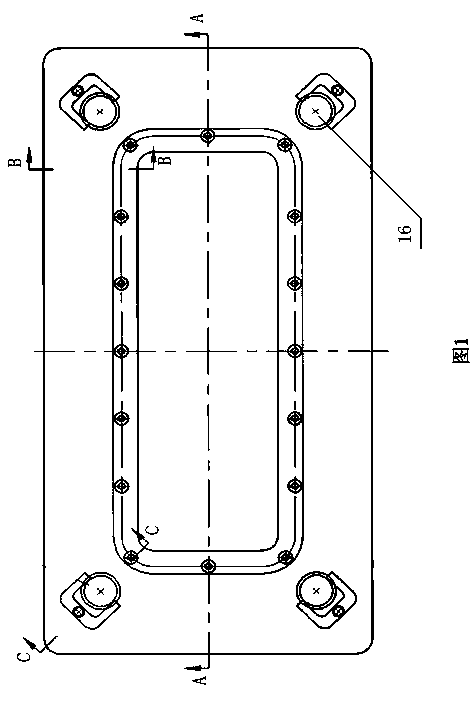

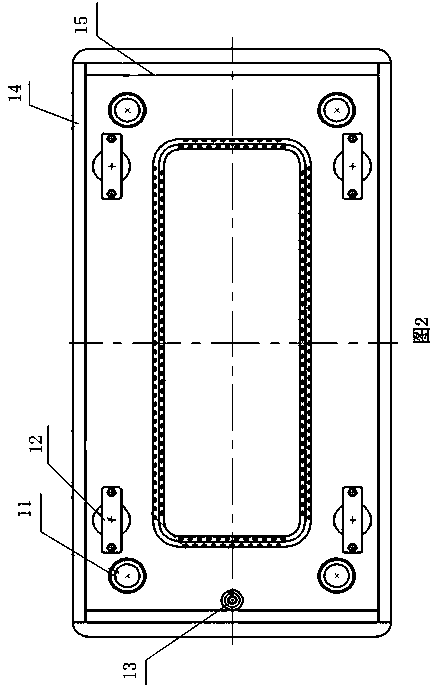

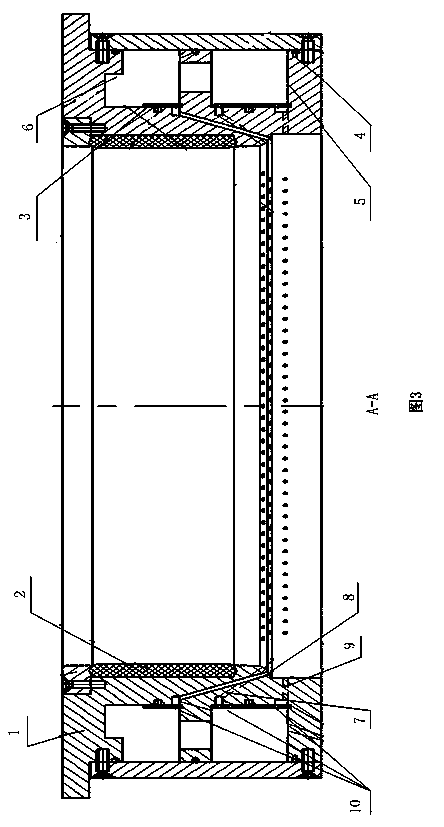

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a crystallizer with variable cooling intensity for aluminum alloy semi-continuous casting, the crystallizer 1 is provided with an upper water chamber 6 and a lower water chamber 5, the bottom of the upper water chamber 6 is provided with a decompression chamber 10, the top of the lower water chamber 5 and The bottom is provided with a decompression chamber 10, the bottom of the upper water chamber 6 is separated from the decompression chamber 10 by installing a water diversion plate 3, the top and bottom of the lower water chamber 5 are separated from the decompression chamber 10 by installing a water diversion plate 3, and the upper water chamber 6 The decompression chamber 10 of the decompression chamber 10 is provided with a third group of cooling water holes 8, the decompression chamber 10 at the top of the lower water chamber 5 is provided with a first group of cooling water holes 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com