Method for recycling copper from copper smelting slag

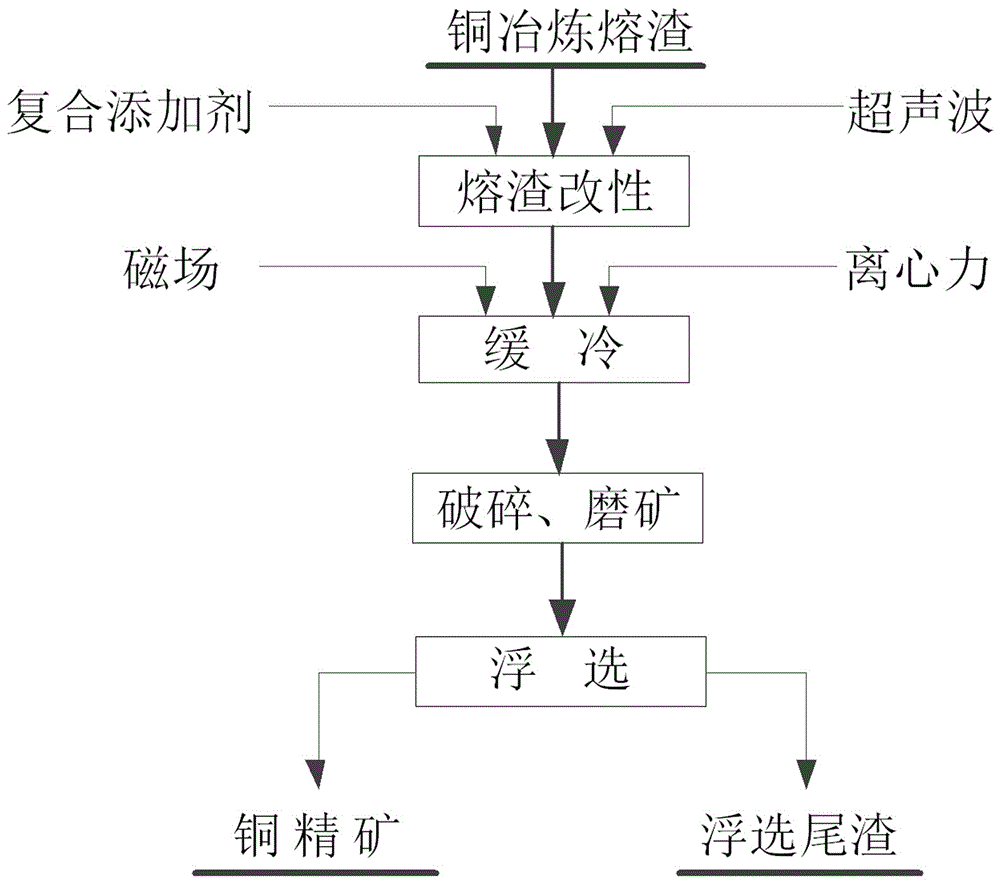

A technology for copper smelting slag and copper recovery, which is applied to the improvement of process efficiency, flotation, solid separation, etc. The effect of small fluctuation of selection index, improvement of flotation, and improvement of flotation recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The composite additive used in the present invention adopts the following preparation method: weighing and mixing pyrite, chalcopyrite, coke powder and sodium humate according to the mass ratio, adding an appropriate amount of water, and then making pellets on a disc The 3-5mm pellets are made in the machine, and finally the pellets are dried until the water content is less than 2%, that is, the composite additive is obtained.

[0031] In the following examples, crushing and grinding are performed by coarsely crushing the modified slag to -5 mm, then crushing to -1 mm by high-pressure roller mill, and then finely grinding in a ball mill.

Embodiment 1

[0035] For the copper grade in the copper smelting slag of electric furnace depletion of 0.60%, add compound additives according to 3% of the mass of copper smelting slag (45% of pyrite, 5% of chalcopyrite, 40% of coke powder, 10% of sodium humate ) for slag modification, fully mixed and melted under the action of ultrasonic field, the modified slag undergoes slow cooling (under the action of centrifugal force and magnetic field, speed 10r / min, magnetic field strength 0.2T), crushing, grinding Finally, copper concentrate is obtained by flotation. The modification is carried out under the conditions of melting temperature 1250°C, cooling rate 1.5°C / min, and cooling end temperature 900°C. Conditions of modified slag in copper flotation: grinding fineness -0.045mm 90%; butyl xanthate 80g / t , after three times of beneficiation and three times of sweeping, the copper rough concentrate grade was 20.56%, and the copper recovery rate was 74.45%.

Embodiment 2

[0037] For the copper grade of 0.60% in the copper smelting slag of electric furnace depletion, add compound additives according to 4% of the mass of copper smelting slag (40% pyrite, 10% chalcopyrite, 45% coke powder, 5% sodium humate) The slag is modified, fully mixed and melted under the action of the ultrasonic field, and the modified slag is slowly cooled (under the action of centrifugal force and magnetic field, the speed is 15r / min, and the magnetic field strength is 0.25T), crushed and ground. , flotation to get copper concentrate. The modification is carried out under the conditions of melting temperature 1300°C, cooling rate 1.5°C / min, and cooling end temperature 900°C. Conditions of modified slag in copper flotation: grinding fineness -0.045mm 90%; butyl xanthate 80g / t , after three times of beneficiation and three times of sweeping, the copper rough concentrate grade was 21.34%, and the copper recovery rate was 76.57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com